down, in, and out. If there is any movement, re-

place the torque arm.

2. Inspect the rubber bushing ends. Replace the

torque arm if there are gaps between the rubber

bushing and the pin or the outer steel sleeve, if

either bushing end contacts a torque arm pin

mounting bolt, if there are cracks in the bushing,

or if part of the rubber bushing extends beyond

the outside diameter of the outer bushing sleeve.

Chalmers Suspension Checking

Chock the front wheels to prevent the vehicle from

moving. Place the transmission in neutral, and re-

lease the spring or driveline brakes before inspecting

the rear suspension.

Power wash the Chalmers rear suspension, or clean

it with a hard-bristle brush before performing a visual

inspection.

1. Inspect the rubber bushings for cracks or other

damage.

Try to move the torque rod ends using your

hands only, and check for any free-play. If free-

play is felt, replace the torque rod end bushing.

Do not use a pry bar to check for free-play. Use

of a pry bar may lead to premature bushing re-

placement. See Group 32 of the

Acterra

®

Work-

shop Manual

for replacement instructions.

2. If equipped with optional shock absorbers, check

for worn, broken, or damaged shock bushings,

heavy corrosion on the shock absorber body, or

fluid leaking from the shock absorber. Replace

the shock absorbers if any of these conditions

are found; see Group 32 of the

Acterra

®

Work-

shop Manual

.

3. Lift the rear of the vehicle and support the frame

on jack stands to unload the suspension compo-

nents. The vehicle is lifted high enough when the

beam ends are off of the saddles. All jack stands

must be of sufficient strength and rigidity to

safely support the vehicle. Do not perform any

work on or around a vehicle that is supported

solely by a lifting device.

Visually inspect the walking beam for cracks, or

other damage. If damage is found, see Group

32 of the

Acterra

®

Workshop Manual

for replace-

ment instructions.

Keep the vehicle supported by the jack stands

for the next operation.

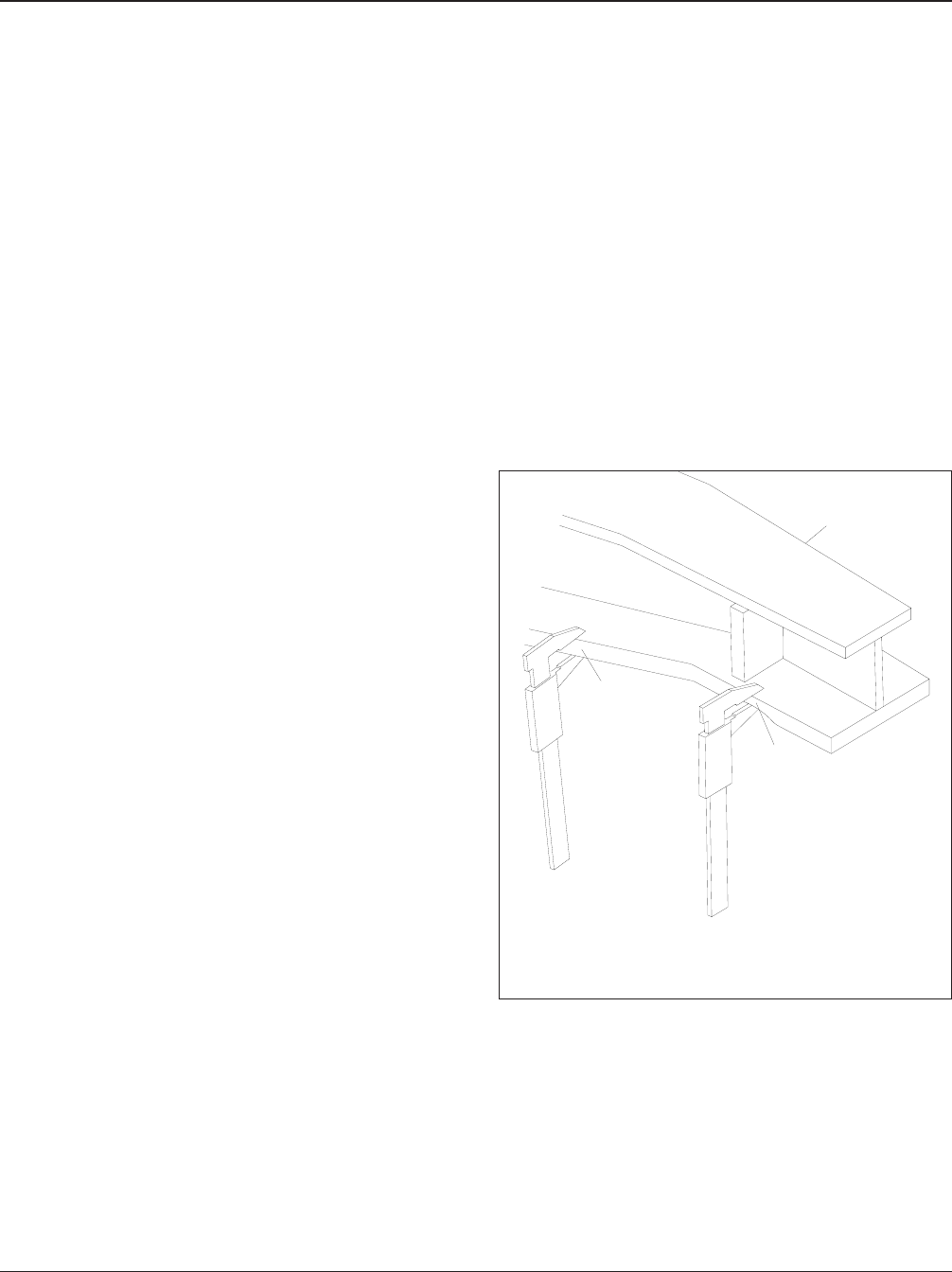

4. Manipulate the walking beam so that a microme-

ter, vernier, or dial caliper can be used to deter-

mine the wear area thickness on the bottom

face. See Fig. 8. Measurements should be taken

a minimum of 1/2 inch (13 mm) from the beam

flange edges to eliminate any edge wear that

may have occurred. Subtract the wear area

thickness (see Fig. 8, Ref. B), from the non-wear

area (see Fig. 8, Ref. A), to determine the

amount of wear.

If the beams show any wear greater than the

allowable 0.062-inch (1.5-mm) wear, a Chalmers

wear plate must be installed, or the walking

beam must be replaced. See Group 32 of the

Acterra

®

Workshop Manual

for repair and re-

placement instructions.

5. Rotate the restrictor cans 360 degrees and in-

spect the cans for cracks, severe corrosion, and

distortion. If any of these conditions are present,

or the restrictor can is missing, replace the re-

strictor can. See Group 32 of the

Acterra

®

Work-

shop Manual

for replacement instructions.

09/27/95

f320432

1

A

B

A. Non-Wear Area

B. Wear Area

1. Walking Beam

Fig. 8, Walking Beam End Wear Thickness

Suspension32

Acterra Maintenance Manual, September 200232/6