2. Check each brake chamber for correct installa-

tion.

2.1 Check each mounting stud for the pres-

ence of prevailing torque locknuts and

hardened flatwashers. Make sure that the

hardened flatwashers are installed be-

tween the mounting bracket and the lock-

nuts. Do not install flatwashers touching

the service (non-pressure) chamber.

2.2 If the locknuts are loose, tighten them.

For correct torque values, see the appli-

cable brake chamber section in Group 42

of the

Acterra

®

Workshop Manual

.

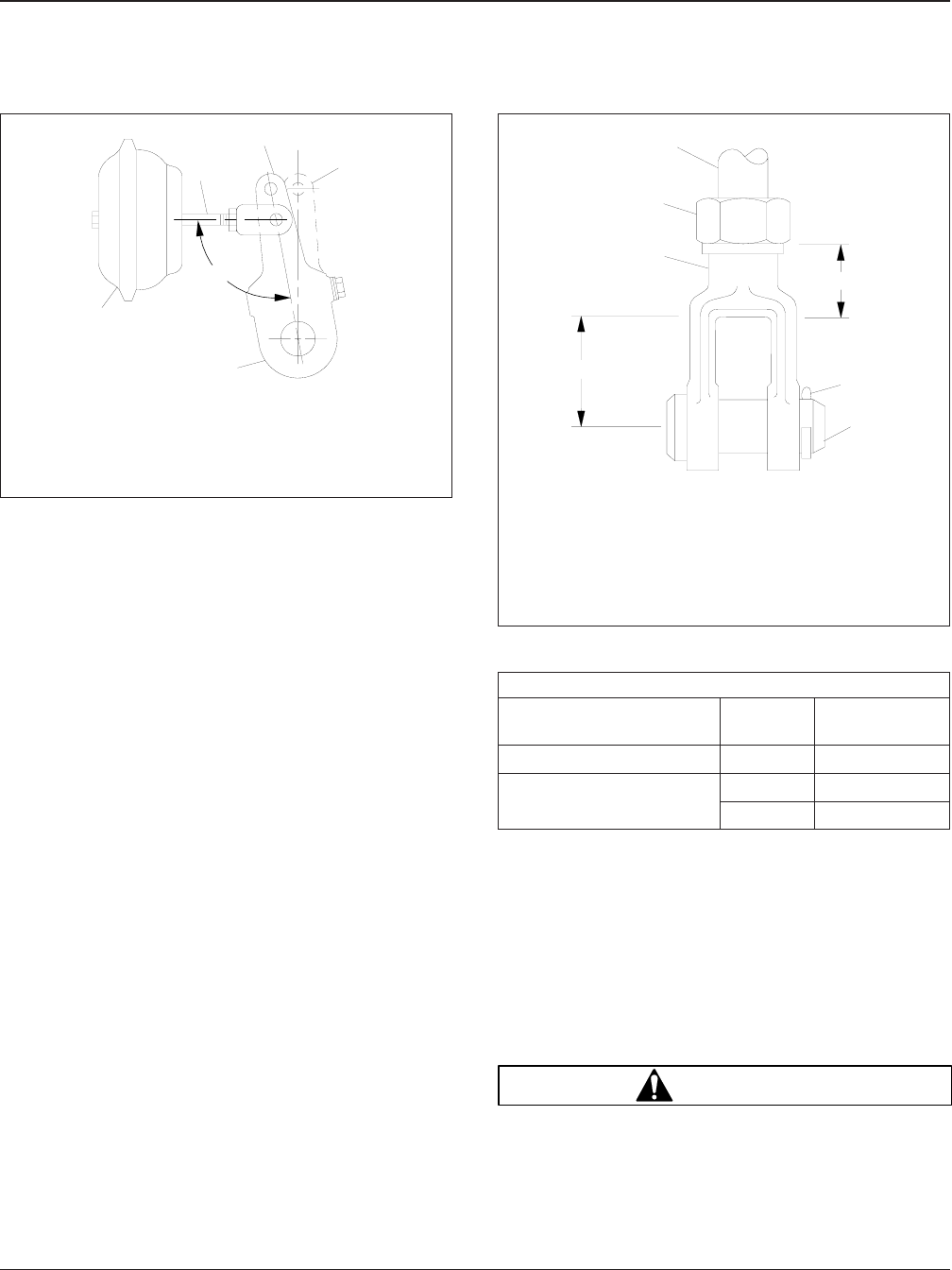

3. Observe the piston rod engagement with the cle-

vis. Engagement of at least 7 threads is required;

there should be 1-inch (25-mm) clearance from

the centerline of the clevis pin hole to the end of

the piston rod. See Fig. 3. Adjust if needed.

4. Check the tightness of the piston rod nut. See

Table 1 for torque values. Tighten if needed.

5. See if the chamber piston rod is in line with the

slack adjuster. Misalignment can cause the pis-

ton rod to rub on the non-pressure chamber and

cause a dragging brake. Reposition the brake

chamber on the mounting bracket, if necessary.

Piston Rod Nut Torque Values

Description

Rod Size:

inch

Torque:

lbf·ft (N·m)

MGM Tandem Chambers All 25–35 (34–47)

Midland Service Chambers

1/2 20–30 (27–41)

5/8 33–90 (45–122)

Table 1, Piston Rod Nut Torque Values

6. Inspect the condition of the hose(s) to the brake

chamber. Check carefully for chafing, restrictions

such as kinking or bending, and make sure the

hoses are properly supported. Replace a dam-

aged hose with the same size hose. With the

service brakes applied, check for leaks at the

hose-to-chamber connections. Any leaks are

probably caused by loose connections or by a

damaged hose fitting. Eliminate all leaks.

WARNING

Read and follow all applicable warnings and in-

structions in Group 42 of the

Acterra

®

Workshop

Manual

for repairs to the service/parking brake

chambers. These chambers contain a power

f420009a

07/27/94

1

3

2

C

B

A

A. Brakes Released

B. Brakes Applied

C. Greater than 90

degree angle

1. Brake Chamber

2. Piston Rod

3. Slack Adjuster

Fig. 2, Angle Between Piston Rod and Slack Adjuster

f420225a

1

2

3

B

A

08/20/93

4

5

A. Minimum of 1-inch (25-mm) clearance between

centerline of clevis pin hole and piston rod end.

B. Minimum of 7 threads engagement.

1. Piston Rod

2. Piston Rod Nut

3. Clevis

4. Cotter Pin

5. Clevis Pin

Fig. 3, Piston Rod Engagement With the Clevis

Brakes 42

Acterra Maintenance Manual, October 2007 42/3