11. Submerge a new oil pan gasket in transmission

fluid for five minutes. Then place the gasket on

the pan; do not use any substance as a gasket

retainer.

IMPORTANT: Do not use gasket-sealing com-

pounds any place inside the transmission or

where they might get washed into the transmis-

sion. Also, nonsoluble vegetable-based cooking

compounds or fibrous greases must not be used

inside the transmission.

12. Install the oil pan and gasket.

12.1 Guide the pan and gasket carefully into

place. Guard against dirt or foreign mate-

rial entering the pan. Retain the pan with

four 5/16–18 washer-head screws, in-

stalled by hand into the corners of the

pan.

12.2 Install the remaining seventeen washer-

head screws by hand, carefully threading

each through the gasket and into the

transmission. Bottom all of the screws

before tightening any of them.

12.3 Evenly tighten all 21 of the screws 10 to

15 lbf·ft (14 to 20 N·m). Check the gasket

fit while the screws are being tightened.

IMPORTANT: The oil pan bolts must main-

tain a minimum torque of 60 lbf·in (680

N·cm) after the oil pan gasket has taken a

set.

13. Install the fill tube at the side of the pan. Tighten

the tube fitting 90 to 100 lbf·ft (122 to 136 N·m).

14. Install the drain plug and gasket, and tighten the

plug 15 to 20 lbf·ft (20 to 27 N·m).

15. Replace the external (auxiliary) fluid filter.

16. Clean the area around the fill tube and remove

the dipstick. Using a clean funnel in the fill tube,

add transmission fluid. See Table 3 for approved

transmission lubricants, and Table 4 for lubricant

capacities.

17. Check and adjust the fluid level using the proce-

dure under "Checking the Fluid Level."

MD Series

When draining transmission fluid, check for evidence

of dirt or water contamination. A small amount of

condensation will appear in the fluid during operation.

Water contamination is normally characterized as a

milky discoloration of the transmission fluid. Obvious

contamination of the transmission fluid indicates a

leak between the water and fluid areas of the trans-

mission cooler. Inspect and pressure-test the cooler

to confirm the leak; replace leaking transmission

coolers.

CAUTION

To prevent dirt from entering the transmission,

use only clean containers and fillers for the trans-

mission fluid. Do not use fillers or containers that

have been used for water or antifreeze. Dirt, water,

or antifreeze could damage the transmission.

1. Park the vehicle on a level surface and apply the

parking brakes.

2. Operate the vehicle until the transmission

reaches normal operating temperature: 160 to

200°F (71 to 93°C).

3. Clean the area around the drain plug and the

transmission fluid pan. Place a drain pan under

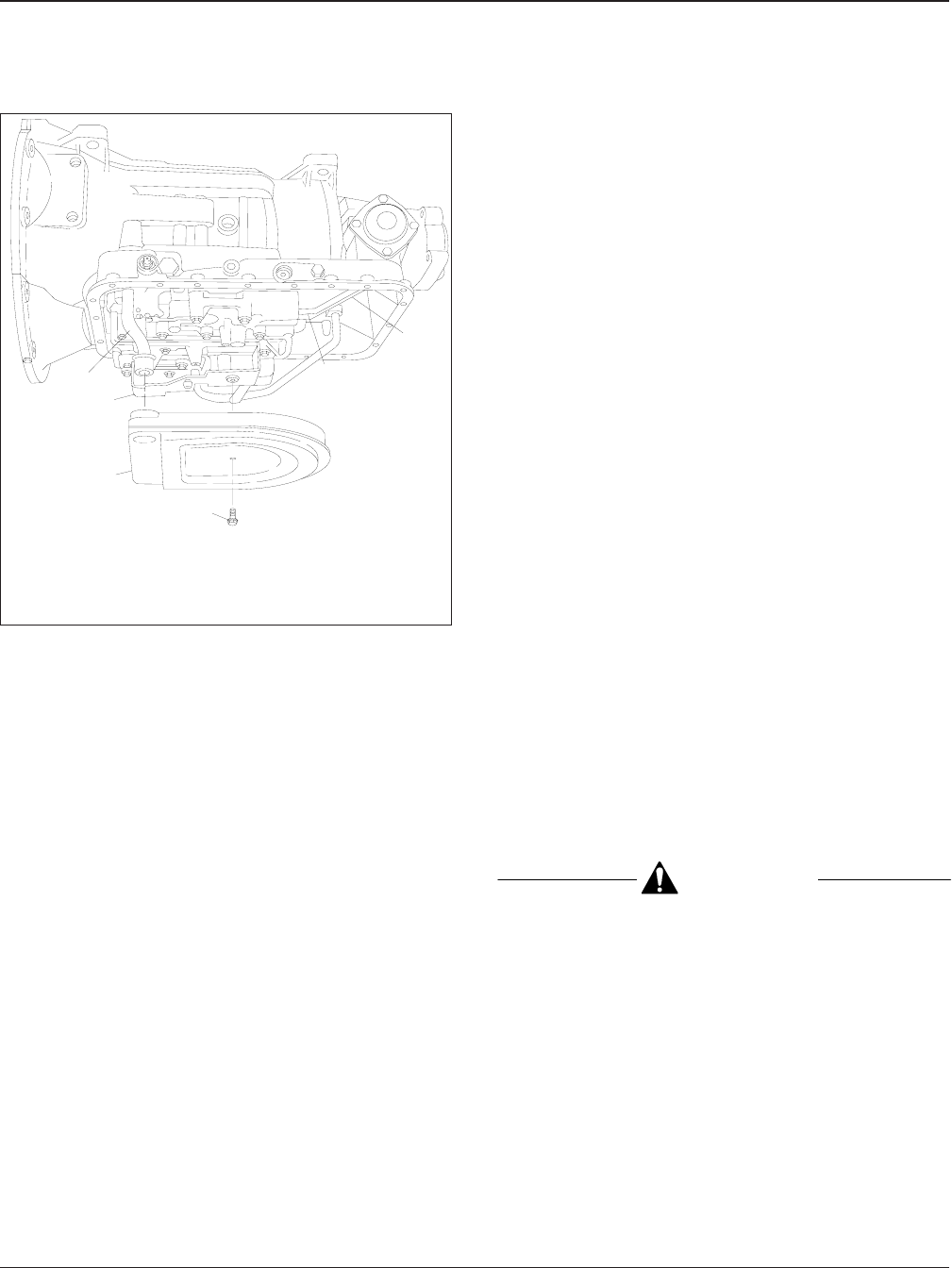

f260133a

1

2

3

4

5

6

10/05/94

1. Fluid Intake Tube

2. Filter Spacer

3. Internal Fluid Filter

4. Washer-Head Screw

5. Governor Pressure

Tube

6. Governor Feed Tube

Fig. 3, Allison AT Series Transmission Filter

Transmission 26

Acterra Maintenance Manual, March 2005 26/5