3. Use a click-type torque wrench to check that

spring hanger bolts are tightened 190 lbf·ft (258

N·m).

4. Use a click-type torque wrench to check that the

5/8-inch torque rod clamp nuts are tightened 125

to 150 lbf·ft (170 to 203 N·m).

5. Use a click-type torque wrench to check that the

two end-nuts for each torque rod are tightened

400 to 450 lbf·ft (540 to 610 N·m).

6. Use a click-type torque wrench to check that

spring retainer bolts are tightened 60 to 80 lbf·ft

(81 to 109 N·m).

32–02 Suspension Lubricating

Sterling Spring Front Suspension

Wipe all dirt from the grease fittings at the forward

spring pin and the spring shackle pins; then apply

multipurpose chassis grease with a pressure gun

until the old grease is forced out.

Sterling Spring Rear Suspension

Single Axle

Lubricate the spring pin by applying multipurpose

chassis grease at the grease fitting. See Fig. 10. Lu-

bricate with a grease gun until grease appears at the

base of the fitting.

Tandem Axle

CAUTION

If the equalizer cap and tube assembly is

equipped with a nonrelief grease fitting, excessive

lubrication can damage the bushings.

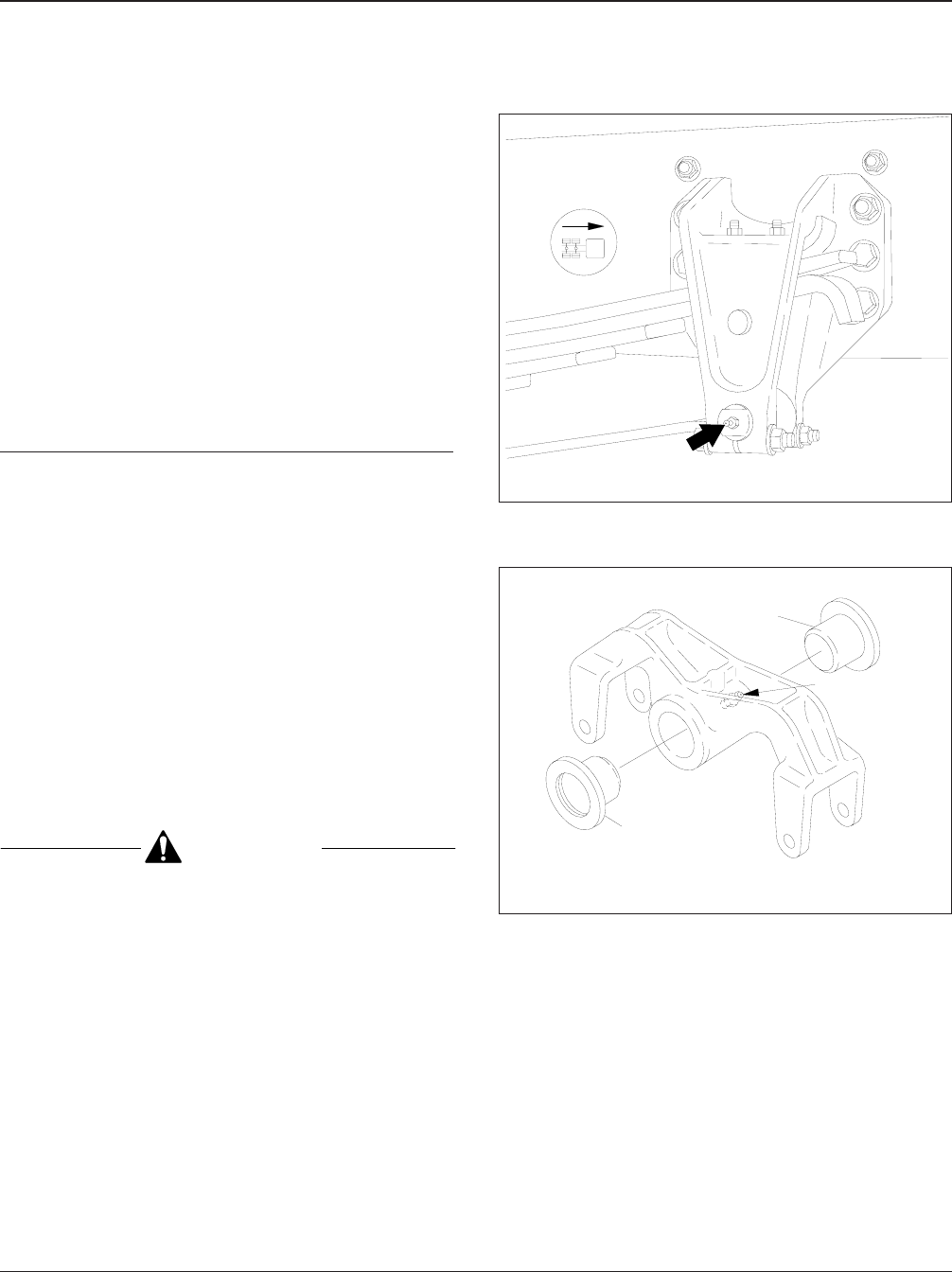

Lubricate the equalizer cap-and-tube assembly bush-

ings by applying multipurpose chassis grease at the

pressure-relief grease fitting. See Fig. 11. Lubricate

with a hand gun or pressure gun until grease is

forced out from the base of the pressure-relief fitting.

Hendrickson Equalizer-Beam

End Bushings and Rubber

Center Bushings

No lubrication is required for the equalizer-beam end

bushings or equalizer-beam rubber center bushings.

f320268a

10/05/94

Fig. 10, Forward Spring Bracket Spring Pin Grease

Fitting (vehicles built before September 15, 2002)

320020a

05/27/93

1

1

A

A. Lubricate here.

1. Cap-and-Tube Assembly Bushing

Fig. 11, Equalizer Assembly Lubrication

Suspension32

Acterra Maintenance Manual, September 200232/8