checked, not the pulley, to isolate the area from

outside interference.

8. Inspect all pulleys for foreign objects, oil, or

grease in the grooves.

Belt Tension Inspection

NOTE: If engine drive belts require adjustment,

see Group 01 of the

Acterra

®

Workshop Manual

for instructions.

Threaded-Adjustment Type

1. Apply the parking brakes, and chock the tires to

prevent the vehicle from moving.

2. Install a belt tension gauge at the center of the

belt’s longest free-span. Check belt tension. See

Table 1 for belt tension specifications.

3. If belt tension is not correct, see Group 01 of the

Acterra

®

Workshop Manual

to adjust belt tension.

Spring-Tension Type

On belts equipped with a spring tensioner, the belt

tension is automatically adjusted. Check that the ten-

sioner is holding tension on the belt by inserting the

end of a breaker bar in the 1/2-inch square hole on

the forward face of the tensioner, and rotating the

tensioner down, away from the belt. When the

breaker bar is slowly released, the tensioner should

return to its original position. If not, see Group 01 of

the

Acterra

®

Workshop Manual

for replacement

instructions.

NOTE: Caterpillar engines are provided with

automatic drive belt tensioners. The following

engines, which appear in Table 1, are provided

with automatic tensioners for the fan and alter-

nator belts.

f150010a

A

B

C

D

E

F

11/21/94

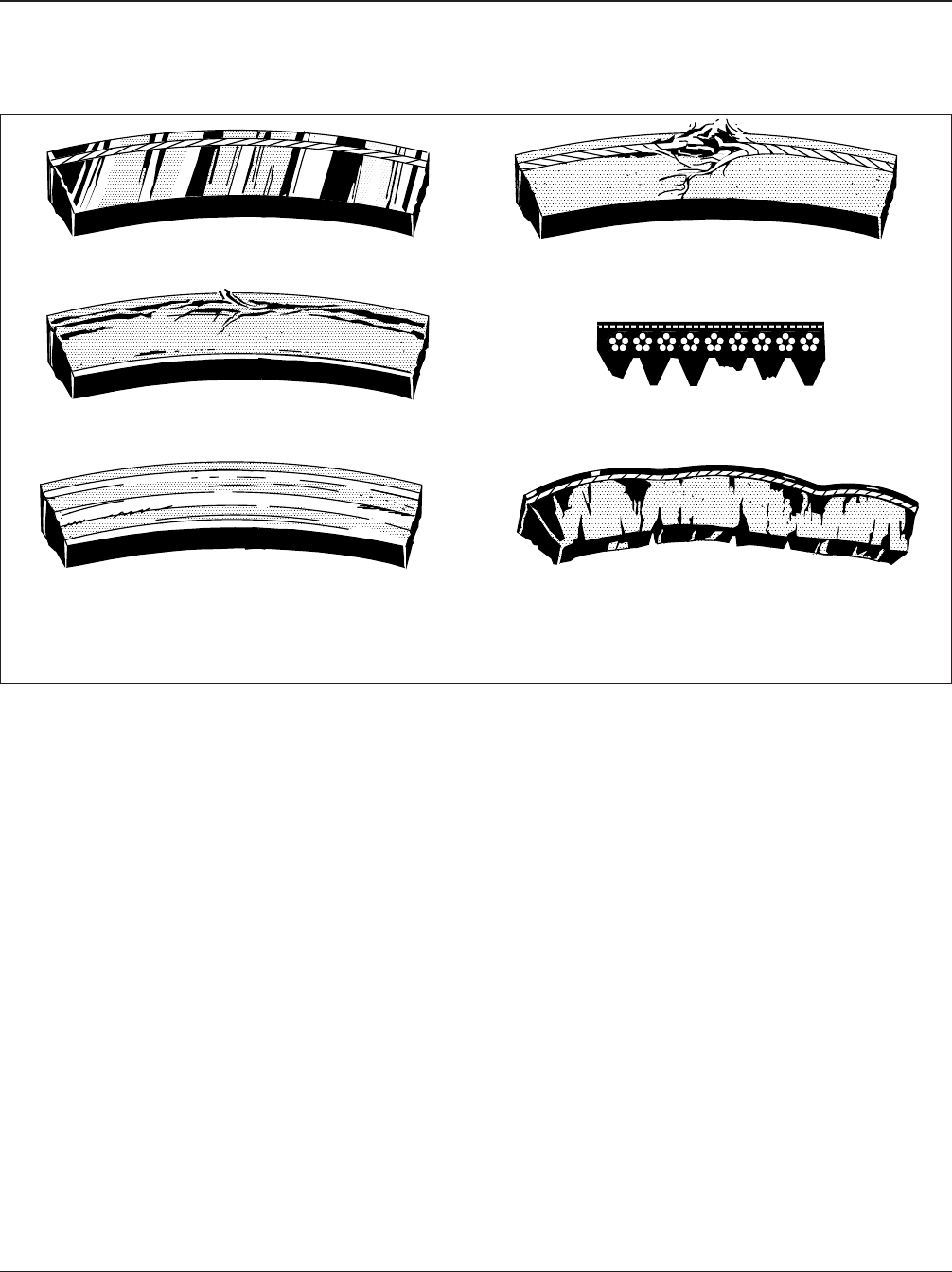

A. Glazing

B. Separating Layers

C. Streaked Sidewalls

D. Tensile Break

E. Uneven Ribs

F. Cracks

Fig. 2, Drive Belt Replacement Conditions

Engine01

Acterra Maintenance Manual, January 200701/2