5B.24

Section 5B

EFI Fuel System

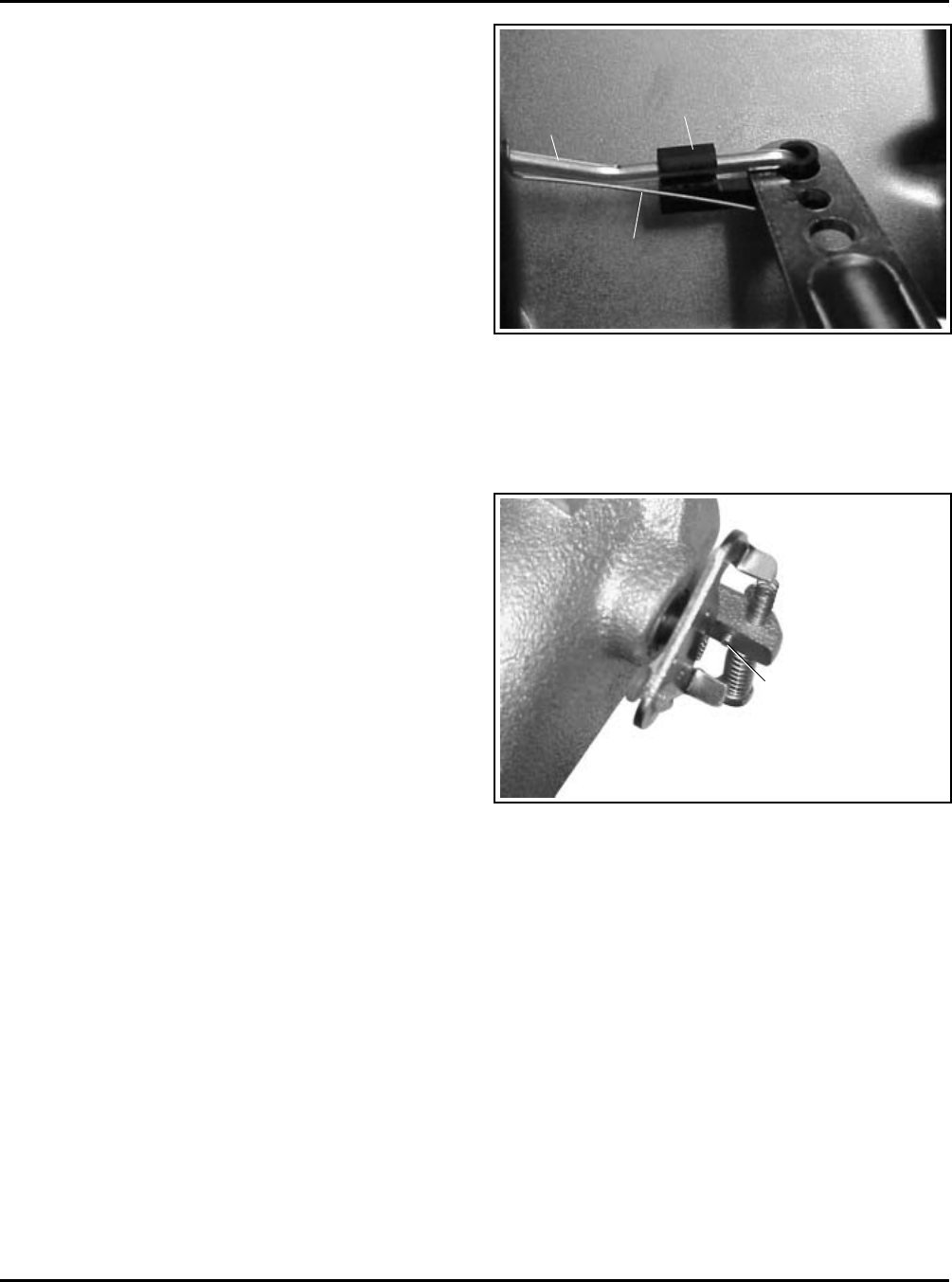

Figure 5B-37. Throttle Linkage/Governor Lever

Connection.

2. Check if the engine has a high-speed throttle stop

screw installed in the manifold casting boss. See

Figure 5B-38.

The idle speed adjustment procedure remains the

same for engines with or without a dampening spring.

Typically, no periodic servicing is necessary in this

area. If however, removal/replacement of the

dampening spring is required, reinstall it as follows:

1. Thread the spring onto the end of idle screw

leaving 1-3 mm (0.039-0.117 in.) of the spring

extending beyond the end of the idle speed screw.

2. Secure spring onto the screw with a small amount

of Permabond

™

LM-737 or equivalent Loctite

®

adhesive. Do not get any adhesive on free coils of

spring.

3. Start the engine and recheck the idle speed

settings, after sufficient warm up. Readjust as

required.

Initial Governor Adjustment

The initial governor adjustment is especially critical on

EFI engines because of the accuracy and sensitivity of

the electronic control system. Incorrect adjustment can

result in overspeed, loss of power, lack of response, or

inadequate load compensation. If you encounter any of

these symptoms and suspect them to be related to the

governor setting, the following should be used to check

and/or adjust the governor and throttle linkage.

If the governor/throttle components are all intact, but

you think there may be a problem with the adjustment,

follow Procedure A to check the setting. If the governor

lever was loosened or removed, go immediately to

Procedure B to perform the initial adjustment.

A. Checking the Initial Adjustment

1. Unsnap the plastic linkage bushing attaching the

throttle linkage to the governor lever. See Figure

5B-37. Unhook the damper spring from the lever,

separate the linkage from the bushing, and

remove the bushing from the lever. Mark the hole

position and unhook the governor spring from the

governor lever.

Linkage

Bushing

Throttle

Linkage

Damper

Spring

High-Speed

Throttle Stop Screw

Figure 5B-38. Throttle Details.

a. On engines without a stop screw, pivot the

throttle shaft and plate assembly into the “Full

Throttle” position. Insert a 1.52 mm (0.060 in.)

feeler gauge between the rear tang of the

throttle shaft plate and the underside of the

manifold boss. Use a locking pliers (needle

nose works best) to temporarily clamp the

parts in this position. See Figure 5B-39.