2.2

Section 2

Special Tools

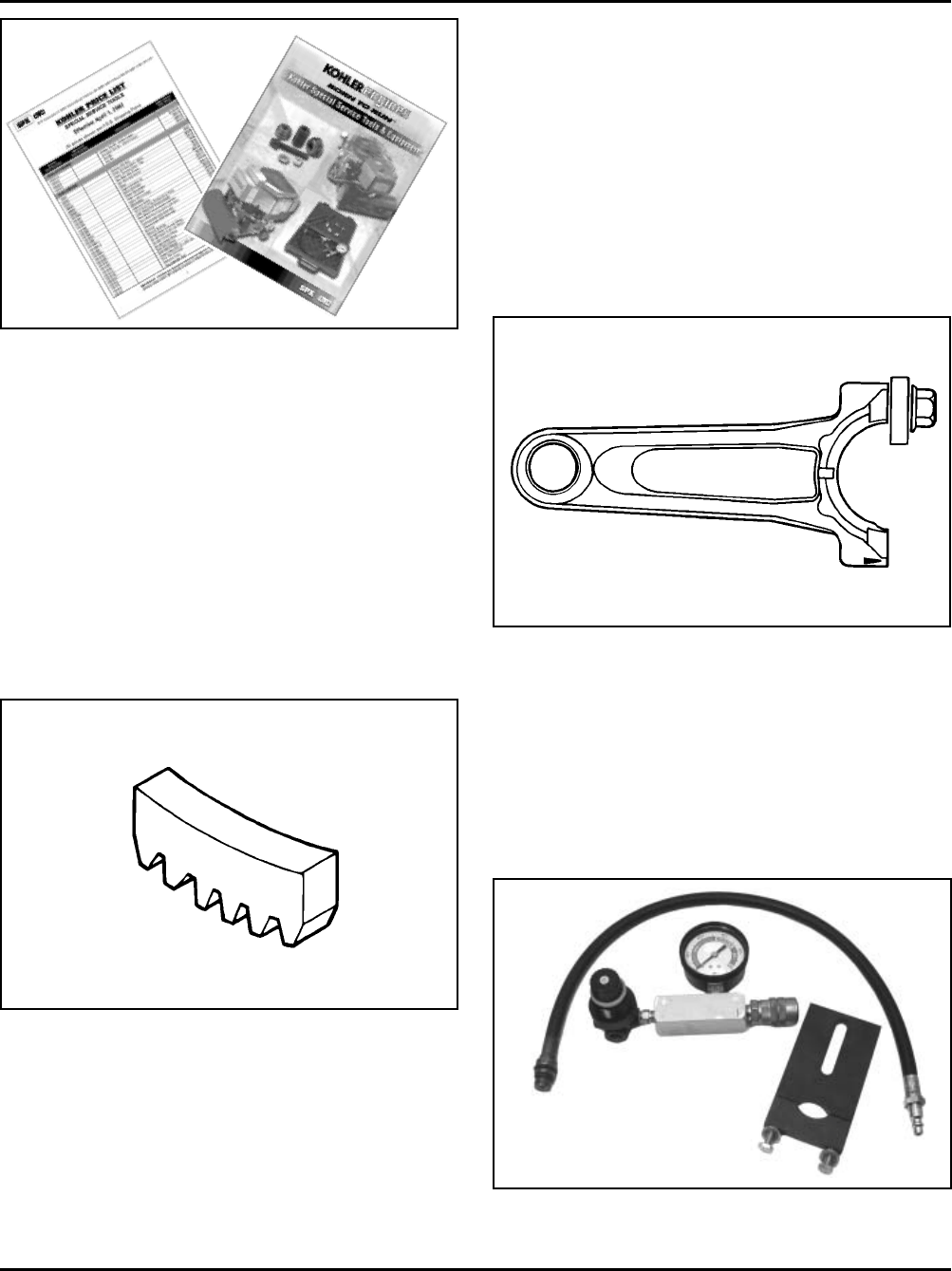

Figure 2-1. Tool Catalog and Price List.

Special Tools You Can Make

Flywheel Holding Tool

Flywheel removal and reinstallation becomes a “snap”

using a handy holding tool which can be made out of an

old “junk” flywheel ring gear as shown in Figure 2-2.

Using an abrasive cut-off wheel, cut out a six tooth

segment of the ring gear as shown. Grind off any burrs

or sharp edges. The segment can be used in place of a

strap wrench. Invert the segment and place it between

the ignition bosses on the crankcase so that the tool

teeth engage the flywheel ring gear teeth. The bosses

will “lock” the tool and flywheel in position for loosening,

tightening or removing with a puller.

Figure 2-2. Flywheel Holding Tool.

Rocker Arm/Crankshaft Tool

If you don’t have a spanner wrench to lift the rocker

arms or turn the crankshaft, you can make a tool for

doing this out of an old junk connecting rod.

Figure 2-3. Rocker Arm/Crankshaft Tool.

Cylinder Leakdown Tester

A Cylinder Leakdown Tester (SPX Part No. KO3219

formerly Kohler 25 761 05-S) is a valuable alternate to a

compression test on these engines. See Figure 2-4. By

pressurizing the combustion chamber from an external

air source, this tool can determine if valves or rings are

leaking. Instructions for using this tester are found in

Section 3 of this manual.

Find a used connecting rod from a 10 HP or larger

engine. Remove and discard the rod cap. If it is a Posi-

Lock rod, you will also need to remove the studs. If it is

a Command rod, you will need to grind off the aligning

steps, so the joint surface is flat. Find a 1 in. long

capscrew with the correct thread size to match the

threads in the connecting rod. Obtain a flat washer

with the correct I.D. to slip on the capscrew and an

O.D. of approximately 1 in. Kohler Part No. 12 468 05-S

can be used if you don’t have the right size on hand.

Assemble the capscrew and washer to the joint

surface of the rod, as shown in Figure 2-3.

Figure 2-4. Cylinder Leakdown Tester.