5B.17

Section 5B

EFI Fuel System

5B

8. Thoroughly clean the area around and including

the throttle body/manifold and the injectors.

9. Disconnect the throttle linkage and damper spring

from the throttle lever. Disconnect the TPS lead

from the harness.

10. Remove the manifold mounting bolts and

separate the throttle body/manifold from the

engine leaving the TPS, fuel rail, air baffle,

injectors and line connections intact. Discard the

old gaskets.

11. Position the manifold assembly over an

appropriate container and turn the key switch

“on” to activate the fuel pump and pressurize the

system. Do not turn switch to “start” position.

12. If either injector exhibits leakage of more than two

to four drops per minute from the tip, or shows

any sign of leakage around the outer shell, turn

the ignition switch off and replace injector as

follows.

13. Depressurize the fuel system following the

procedure in the fuel warning on page 5B.2.

Remove the two fuel rail mounting screws.

14. Clean any dirt accumulation from the sealing/

mounting area of the faulty injector(s) and

disconnect the electrical connector(s).

15. Pull the retaining clip off the top of the injector(s)

and remove from manifold.

16. Reverse the appropriate procedures to install the

new injector(s) and reassemble the engine. Use

new O-Rings any time an injector is removed

(new replacement injectors include new O-Rings).

Lubricate O-Rings lightly with oil. Torque the fuel

rail and blower housing mounting screws to

3.9 N·m (35 in. lb.), and the intake manifold and

air cleaner mounting screws to 9.9 N·m

(88 in. lb.).

Injector problems due to dirt or clogging are generally

unlikely, due to the design of the injectors, the high fuel

pressure, and the detergent additives in the gasoline.

Symptoms that could be caused by dirty/clogged

injectors include rough idle, hesitation/stumble during

acceleration, or triggering of fault codes related to fuel

delivery. Injector clogging is usually caused by a

buildup of deposits on the director plate, restricting the

flow of fuel, resulting in a poor spray pattern. Some

contributing factors to injector clogging include higher

than normal operating temperatures, short operating

intervals, and dirty, incorrect, or poor quality fuel.

Cleaning of clogged injectors is not recommended;

they should be replaced. Additives and higher grades

of fuel can be used as a preventative measure if

clogging has been a problem.

Ignition System

General

A high voltage, solid state, battery ignition system is

used with the EFI system. The ECU controls the

ignition output and timing through transistorized control

of the primary current delivered to the coils. Based on

input from the speed sensor, the ECU determines the

correct firing point for the speed at which the engine is

running. At the proper instant, it releases the flow of

primary current to the coil. The primary current

induces high voltage in the coil secondary, which is

then delivered to the spark plug. Each coil fires every

revolution, but every other spark is “wasted.”

Service

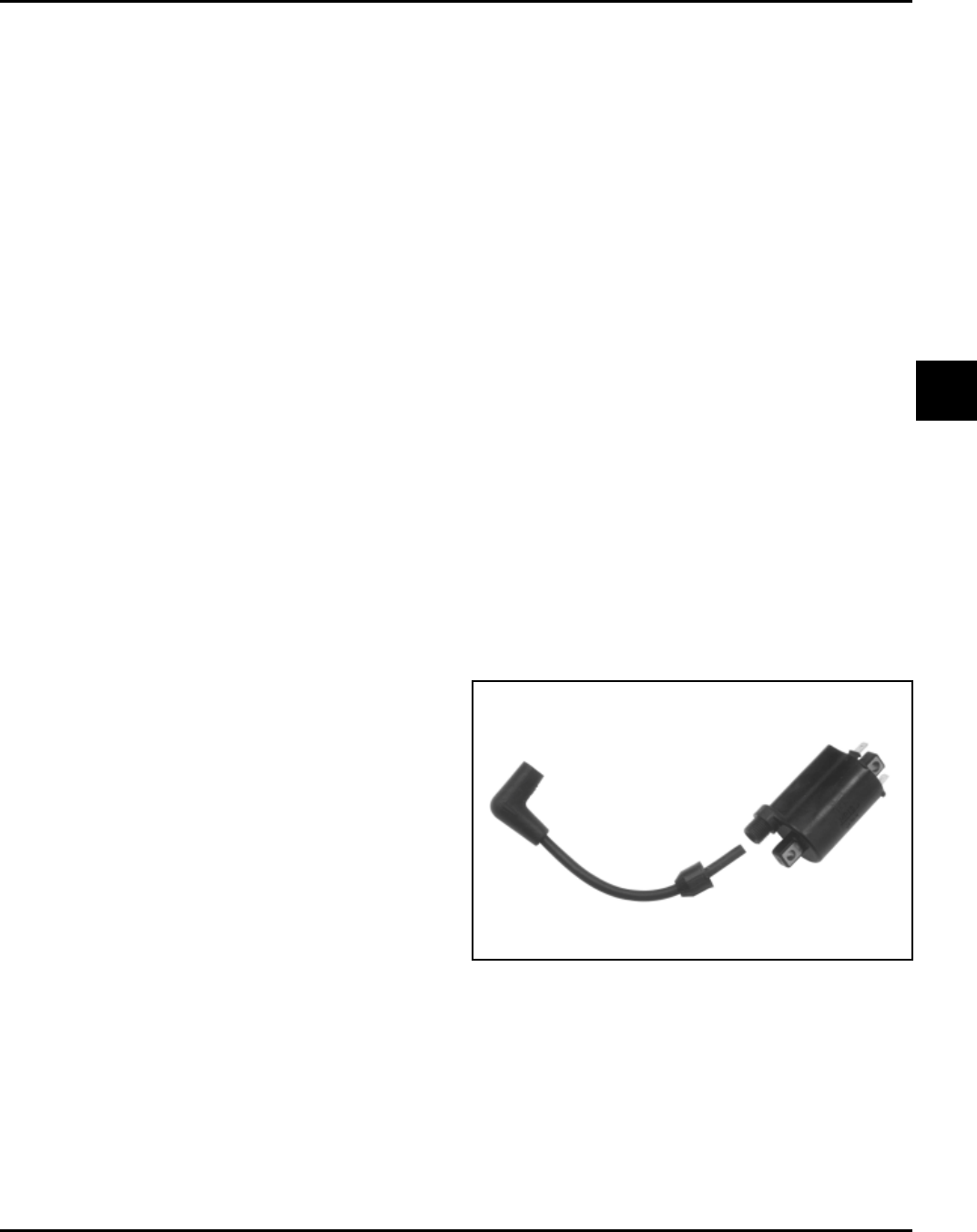

Except for removing the spark plug lead by

unscrewing it from the secondary tower (see Figure

5B-22), no coil servicing is possible. If a coil is

determined to be faulty, replacement is necessary. An

ohmmeter may be used to test the wiring and coil

windings.

Figure 5B-22. Ignition Coil.

NOTE: Do not ground the coils with the ignition ‘‘on,’’

as they may overheat or spark.

Testing

1. Disconnect the main harness connector from

ECU.

“35 Pin” (MA 1.7) Metal-Cased ECU: Locate

pins #1 and #19 in the 35 pin connector. See

page 5B.28.