11.15

Section 11

Reassembly

11

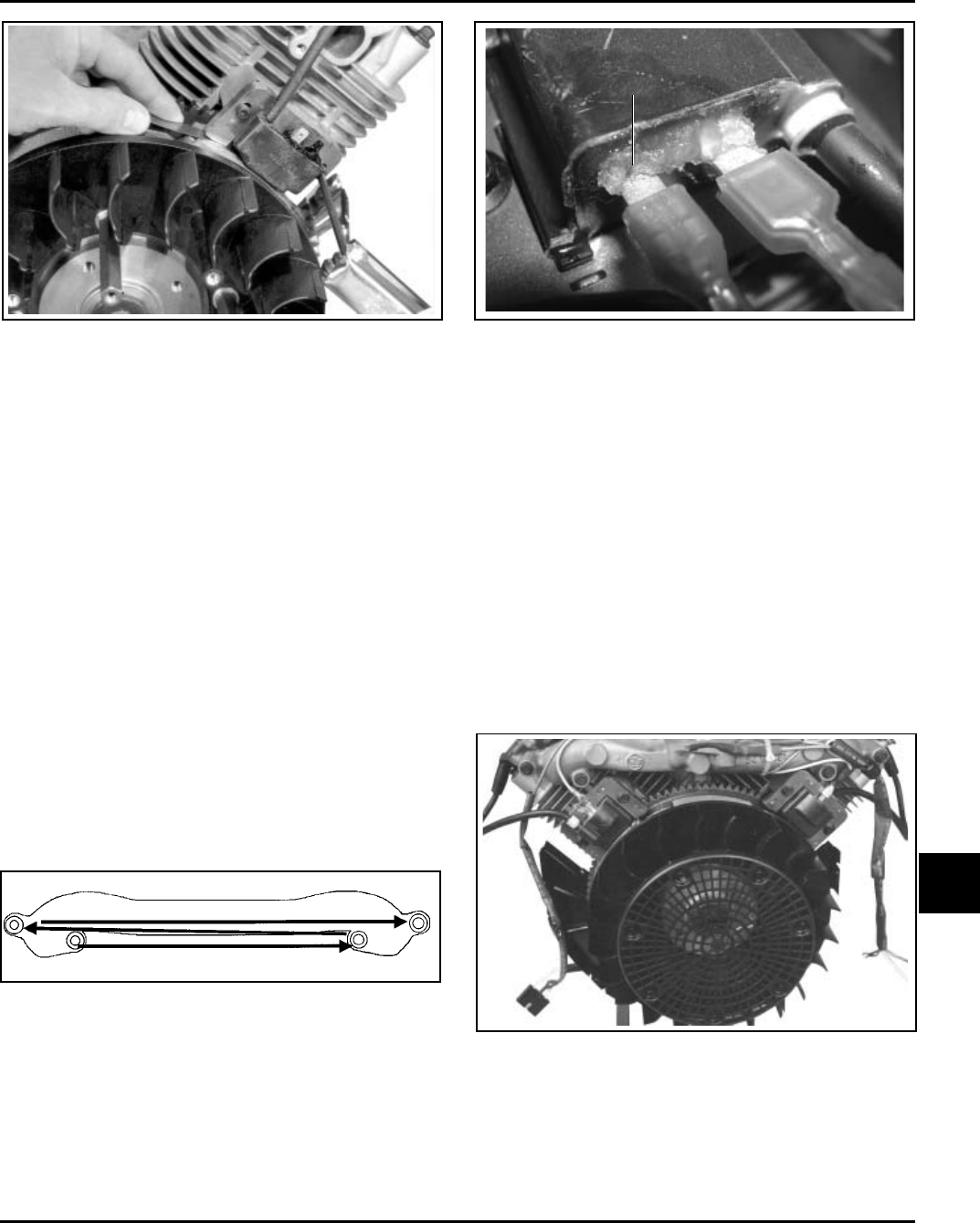

Figure 11-50. Setting Ignition Module Air Gap.

6. Torque the screws to 4.0 N·m (35 in. lb.).

7. Repeat steps 4 through 6 for the other ignition

module.

8. Rotate the flywheel back and forth checking for

clearance between the magnet and ignition

modules. Make sure the magnet does not strike

the modules. Check the gap with a feeler gauge

and readjust if necessary. Final Air Gap:

0.280/0.330 mm. (0.011/0.013 in.).

Install Intake Manifold

1. Install the intake manifold and new gaskets or

O-Rings (plastic manifold), with wiring harness

attached, to the cylinder heads. Slide any wiring

harness clips onto the appropriate bolts before

installing. Make sure the gaskets are in the proper

orientation. Torque the four screws in two stages,

first to 7.4 N·m (66 in. lb.), then to 9.9 N·m

(88 in. lb.), using the sequence shown in Figure

11-51.

1

2

3

4

Sealant

Figure 11-51. Intake Manifold Torque Sequence.

Figure 11-52. Sealant Applied to Terminals.

NOTE: If the wires were disconnected from the

ignition modules on engines with SMART-

SPARK

™

, reattach the leads and seal the

base of the terminal connectors with GE/

Novaguard G661 (Kohler Part No.

25 357 11-S) or Fel-Pro Lubri-Sel dielectric

compound. The beads should overlap

between the terminals* to form a solid bridge

of compound. See Figure 11-52. Do not put

any compound inside the terminals.

*The 24 584 15-S ignition modules have a

separator barrier between the terminals. On these

modules, seal the base of the terminals, but it is

not necessary to have overlapping beads of

sealant between the connections.

Figure 11-53. Routing of Wiring Harness.

2. Connect the kill lead to the tab terminal on

standard ignition modules. See Figure 11-54.