11.3

Section 11

Reassembly

11

Figure 11-9. Installing Piston Assembly Using Ring

Compressor Tool.

5. Install the inner rod cap to the connecting rod

using the two hex. flange screws. Three different

types of connecting rod bolts have been used and

each has a different torque value. If 8 mm straight

shank type bolts are used, torque in increments to

22.7 N·m (200 in. lb.). If 8 mm step-down bolts

are used, torque in increments to 14.7 N·m

(130 in. lb.). If 6 mm straight shank bolts are

used, torque in increments to 11.3 N·m

(100 in. lb.). Illustrated instructions are provided

in the service rod package. See Figures 11-10

and 11-11.

NOTE: Align the chamfer of the connecting rod

with the chamfer of its mating end cap.

When installed, the flat faces of the

connecting rods should face each other.

The faces with the raised rib should be

toward the outside.

Figure 11-7. Installing Crankshaft.

Install Connecting Rods with Pistons and

Rings

NOTE: The cylinders are numbered on the

crankcase. Make sure to install the piston,

connecting rod and end cap into its

appropriate cylinder bore as previously

marked at disassembly. Do not mix the end

caps and connecting rods.

NOTE: Proper orientation of the piston/connecting

rod assemblies inside the engine is extremely

important. Improper orientation can cause

extensive wear or damage. Be certain the

pistons and connecting rods are assembled

exactly as shown in Figure 11-8.

1. Stagger the piston rings in the grooves until the

end gaps are 120° apart. The oil ring rails should

also be staggered.

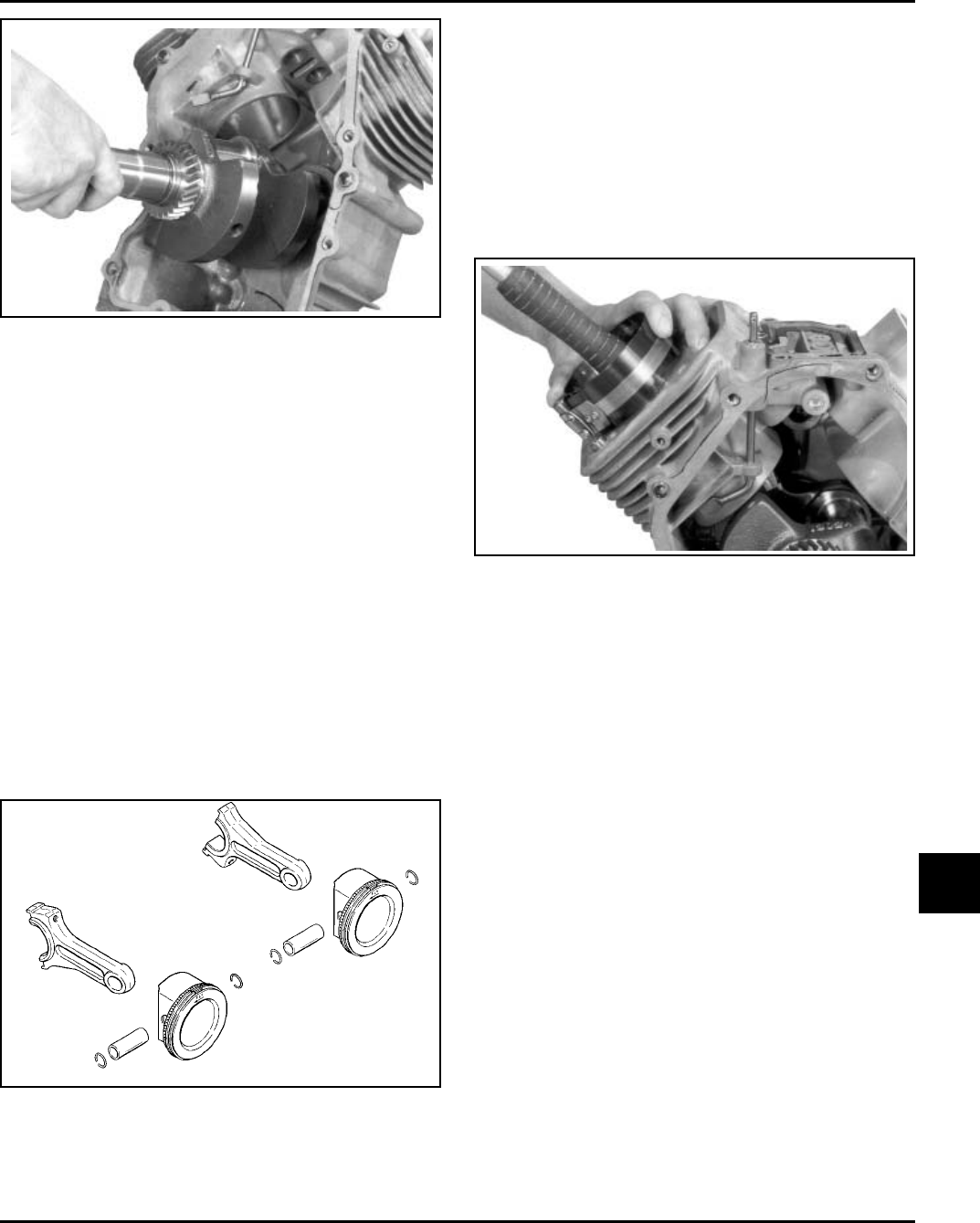

Figure 11-8. Piston, Connecting Rod and End Cap

Detail.

2. Lubricate the cylinder bore, piston, and piston

rings with engine oil. Compress the rings of the #1

piston using a piston ring compressor.

Cylinder #1

Cylinder #2

3. Lubricate the crankshaft journals and connecting

rod bearing surfaces with engine oil.

4. Make sure the “Fly” stamping on piston is facing

towards the flywheel side of the engine. Use a

hammer with a rubber grip and gently tap the

piston into the cylinder as shown in Figure 11-9.

Be careful that the oil ring rails do not spring free

between the bottom of the ring compressor and

top of the cylinder.