11.1

Section 11

Reassembly

11

Section 11

Reassembly

General

NOTE: Make sure the engine is assembled using all

specified torque values, tightening sequences

and clearances. Failure to observe

specifications could cause severe engine

wear or damage. Always use new gaskets.

Make sure all traces of any cleaner are removed

before the engine is assembled and placed into

operation. Even small amounts of these cleaners can

quickly break down the lubricating properties of engine

oil.

Check the closure plate, crankcase, cylinder heads,

and valve covers to be certain that all of the old RTV

has been removed. Use gasket remover, lacquer

thinner, or paint remover to remove any remaining

traces. Clean the surfaces with isopropyl alcohol,

acetone, lacquer thinner, or electrical contact cleaner.

Typical Reassembly Sequence

The following sequence is suggested for complete

engine reassembly. This procedure assumes that all

components are new or have been reconditioned, and

all component subassembly work has been completed.

The sequence may vary to accommodate options or

special equipment. Detailed procedures follow.

1. Install flywheel end oil seal.

2. Install governor cross shaft.

3. Install crankshaft.

4. Install connecting rods with pistons and rings.

5. Install camshaft.

6. Install closure plate assembly.

7. Install stator and backing plates.

8. Install flywheel.

9. Install fan and grass screen.

10. Install hydraulic lifters.

11. Install cylinder heads.

12. Install ignition modules.

13. Install intake manifold.

14. Install breather cover and inner baffles.

15. Install blower housing and outer baffles.

16. Install electric starter motor.

17. Install fuel pump.

18. Install carburetor.

19. Install external governor controls.

20. Install throttle and choke controls.

21. Install Oil Sentry

™

.

22. Install control panel (if so equipped).

23. Install valve covers.

24. Install air cleaner assembly (see Section 4).

25. Install muffler.

26. Install oil filter and add oil to crankcase.

27. Connect spark plug leads.

Install Flywheel End Oil Seal

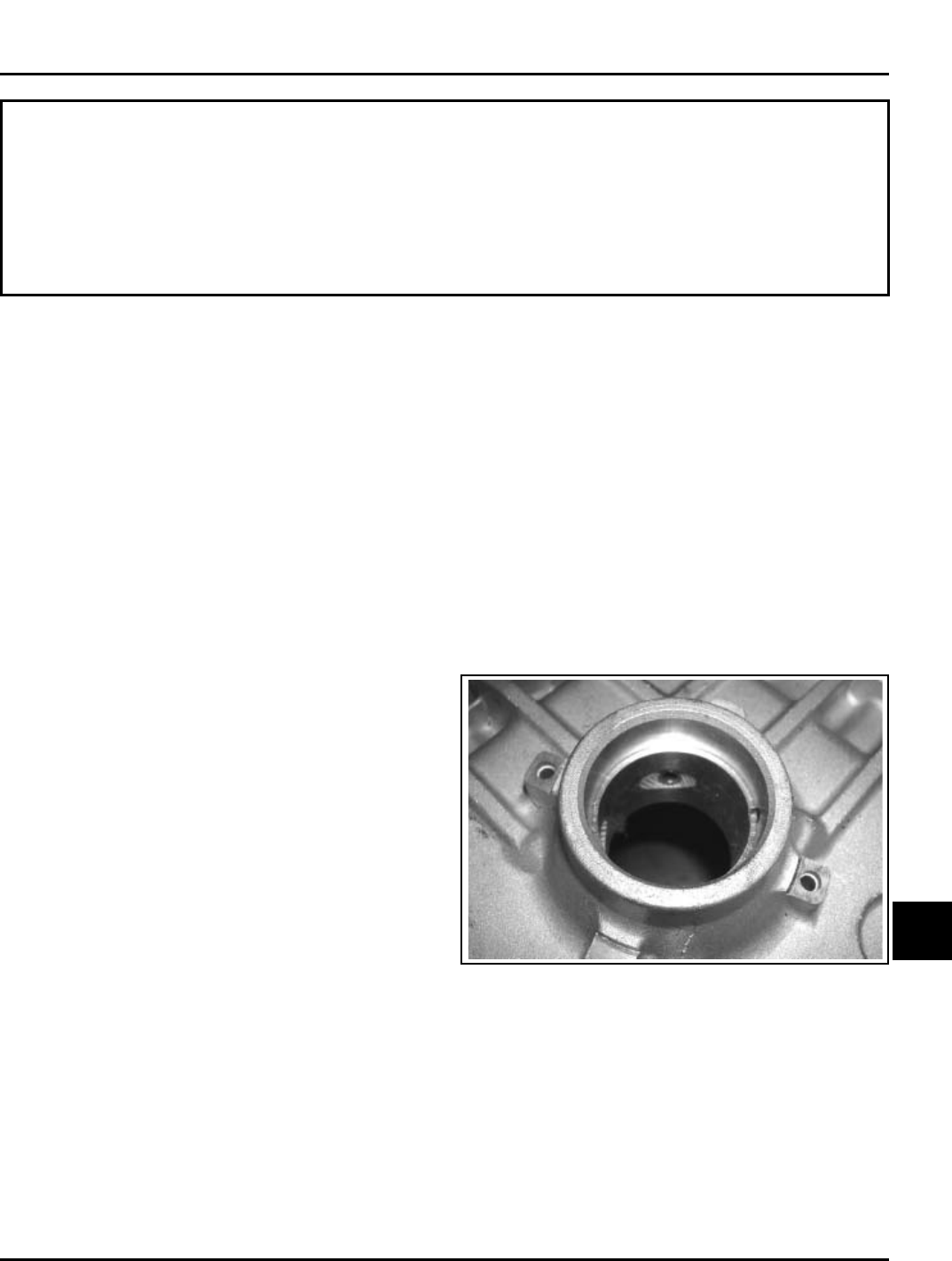

1. Make sure that the seal bore of the crankcase is

clean and free of any nicks or burrs. See Figure

11-1.

CH18-745

Figure 11-1. Seal Bore of Crankcase.

2. Apply a light coat of clean engine oil to the outside

diameter of the oil seal.

3. Drive the oil seal into the crankcase using a seal

driver. Make sure the oil seal is installed straight

and true in the bore and that the tool bottoms

against the crankcase. See Figure 11-2.