11.13

Section 11

Reassembly

11

Figure 11-43. Installing New Mounting Studs to

Specified Height.

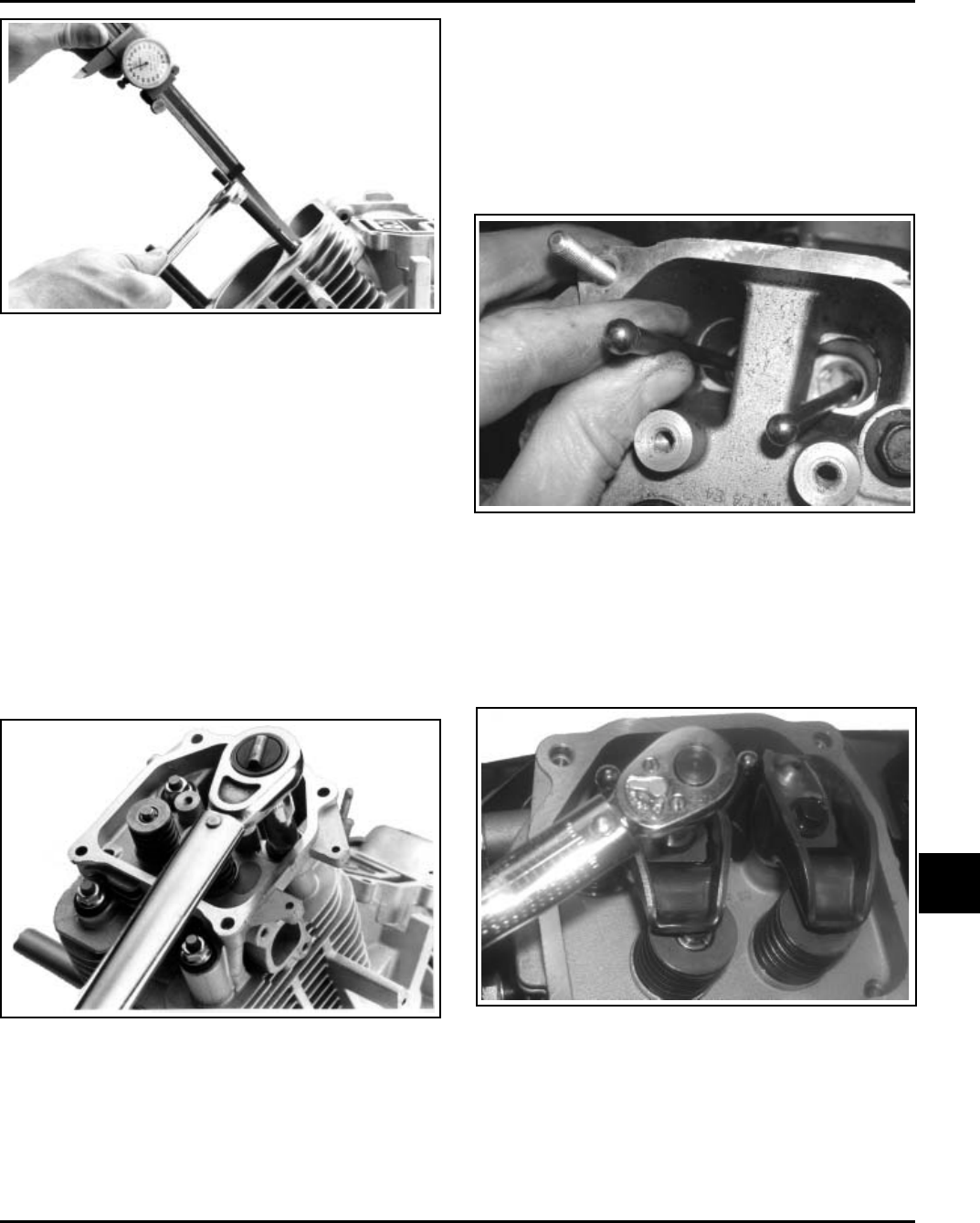

4. Check that the dowel pins are in place and install

a new cylinder head gasket (printing up).

5. Install the cylinder head. Match the numbers on

the cylinder heads and the crankcase. See Figure

11-36. Make sure the head is flat on the gasket

and dowel pins.

6. Lightly lubricate the exposed (upper) threads of

the studs with engine oil. Install a flat washer and

hex. nut onto each of the mounting studs. Torque

the hex. nuts in two stages; first to 16.9 N·m

(150 in. lb.), then finally to 33.9 N·m (300 in. lb.),

following the sequence in Figure 11-42.

Figure 11-46. Torquing Rocker Arm Screws.

3. Torque the hex. flange screws to 11.3 N·m

(100 in. lb.). Repeat for the other rocker arm.

4. Use a spanner wrench or rocker arm lifting tool

(see Section 2), to lift the rocker arms and

position the push rods underneath. See Figure

11-47.

NOTE: Push rods should always be installed in the

same position as before disassembly.

1. Note the mark or tag identifying the push rod as

either intake or exhaust and cylinder #1 or #2. Dip

the ends of the push rods in engine oil and install,

making sure that each push rod ball seats in its

hydraulic lifter socket. See Figure 11-45.

Figure 11-44. Torquing the Cylinder Head Mounting

Nuts (Stud Design).

Install Push Rods and Rocker Arms

Early models used hollow push rods with special

rocker arms. They are not interchangeable with the

later/current style “solid” push rods and associated

rocker arms. Do not mix these. A replacement kit is

available with “solid” components.

Figure 11-45. Install Push Rods in Their Original

Position.

2. Apply grease to the contact surfaces of the rocker

arms and rocker arm pivots. Install the rocker

arms and rocker arm pivots on one cylinder head,

and start the two hex. flange screws. See Figure

11-46.