11.6

Section 11

Reassembly

Remove the closure plate. If end play requires

adjustment, remove the original spacer and install the

appropriate size shim spacer in its place. Then follow

the procedure under “Install Closure Plate Assembly.”

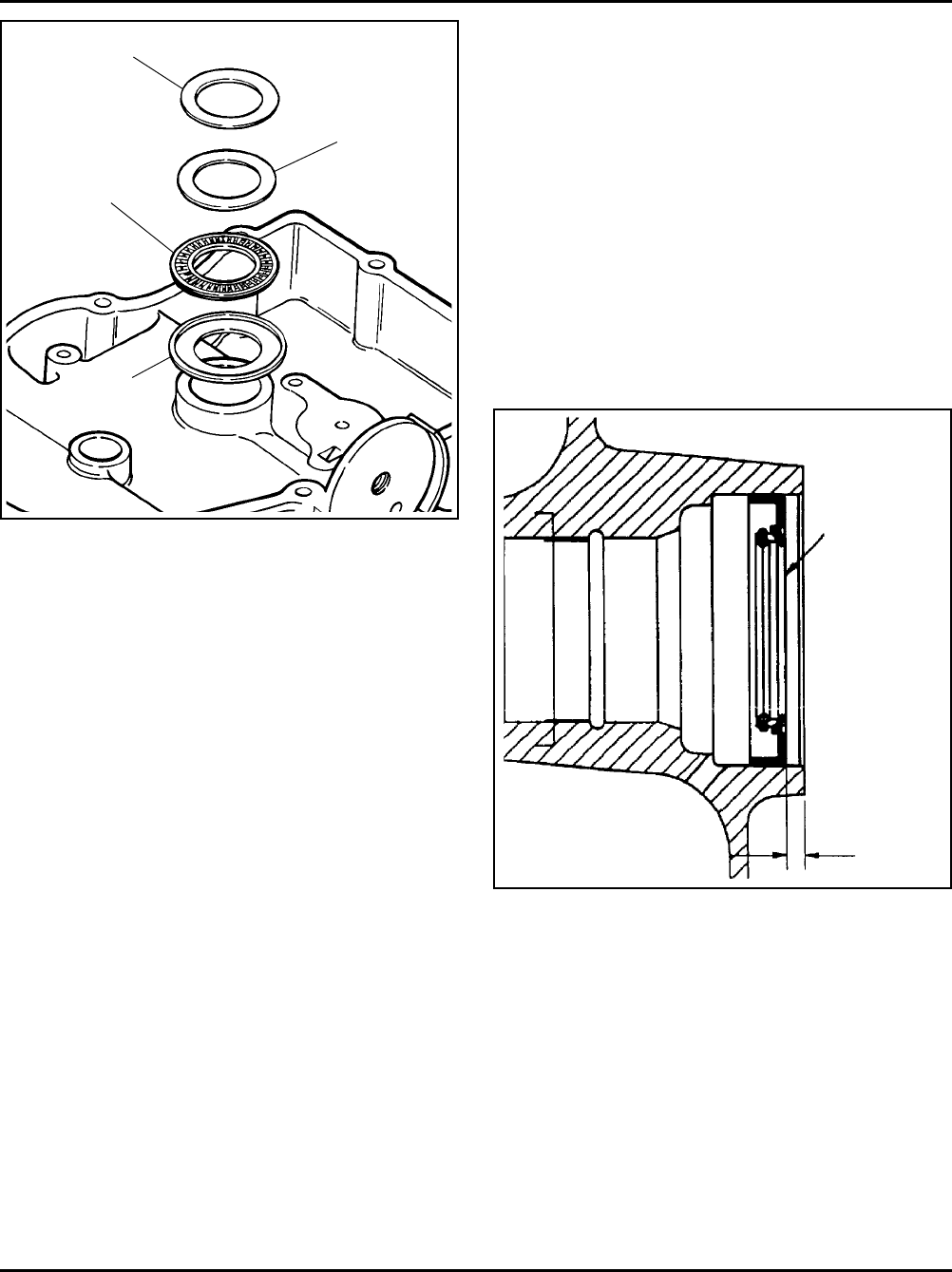

Install Closure Plate Oil Seal

1. Check to make sure that there are no nicks or

burrs in the crankshaft bore of the closure plate.

2. Apply a light coat of engine oil to the outside

diameter of the oil seal.

3. Drive the oil seal into the closure plate using a

seal driver. Make sure the oil seal is installed

straight and true in the bore to the depth shown in

Figure 11-18.

Figure 11-17. Correct Sequence of Thrust Bearing,

Washer and Shim in Closure Plate.

The race for the thrust bearing presses loosely into the

closure plate. If it is not already installed, push it into

the crankshaft bore inside the closure plate. Pack the

thrust bearing with heavy grease and stick the bearing

into the race. Wipe some grease on the face of the

thrust washer and stick it onto the thrust bearing. Wipe

some grease on the face of the original shim spacer

and stick it onto the thrust washer.

Install the closure plate onto the crankcase without

applying RTV sealant and secure it with only two or

three of the fasteners at this time. Use a dial indicator

to check the crankshaft end play. End play should be

0.05/0.50 mm (0.0020/0.0197 in.), except for CH25

engines below Serial No. 2403500008 end play should

be 0.050/0.75 mm (0.0020/0.0295 in.). Shim spacers

are available in the three color coded thicknesses

listed below if adjustment is needed.

Crankshaft End Play Shims

GREEN 0.8366-0.9127 mm

(0.8750 mm/0.034 in. Nominal)

YELLOW 1.0652-1.1414 mm

(1.1033 mm/0.043 in. Nominal)

RED 1.2938-1.3700 mm

(1.3319 mm/0.052 in. Nominal)

Closure

Plate

Bearing

Race

Thrust Shim

Needle Thrust

Bearing

Thrust

Washer

Oil Seal

8.0 mm

(.314 in.)

Seal Depth

Figure 11-18. Oil Seal Depth in Closure Plate.

Install Closure Plate Assembly

RTV sealant is used as a gasket between the closure

plate and the crankcase. Refer to Section 2 for a listing

of approved sealants. Always use fresh sealant. Using

outdated sealant can result in leakage.

1. Be sure the sealing surfaces have been cleaned

and prepared as described at the beginning of

Section 10 or in Service Bulletin 252.

2. Check to make sure that there are no nicks or

burrs on the sealing surfaces of the closure plate

or crankcase.