5B.15

Section 5B

EFI Fuel System

5B

When the key switch is on and the relay is closed, the

fuel rail is pressurized, and voltage is present at the

injector. At the proper instant, the ECU completes the

ground circuit, energizing the injector. The valve needle

in the injector is opened electromagnetically, and the

pressure in the fuel rail forces fuel down through the

inside. The “director plate” at the tip of the injector (see

inset) contains a series of calibrated openings which

directs the fuel into the manifold in a cone-shaped

spray pattern.

Service

Injector problems typically fall into three general

categories: electrical, dirty/clogged, or leakage. An

electrical problem usually causes one or both of the

injectors to stop functioning. Several methods may be

used to check if the injectors are operating.

1. With the engine running at idle, feel for

operational vibration, indicating that they are

opening and closing.

2. When temperatures prohibit touching, listen for a

buzzing or clicking sound with a screwdriver or

mechanic’s stethoscope (see Figure 5B-19).

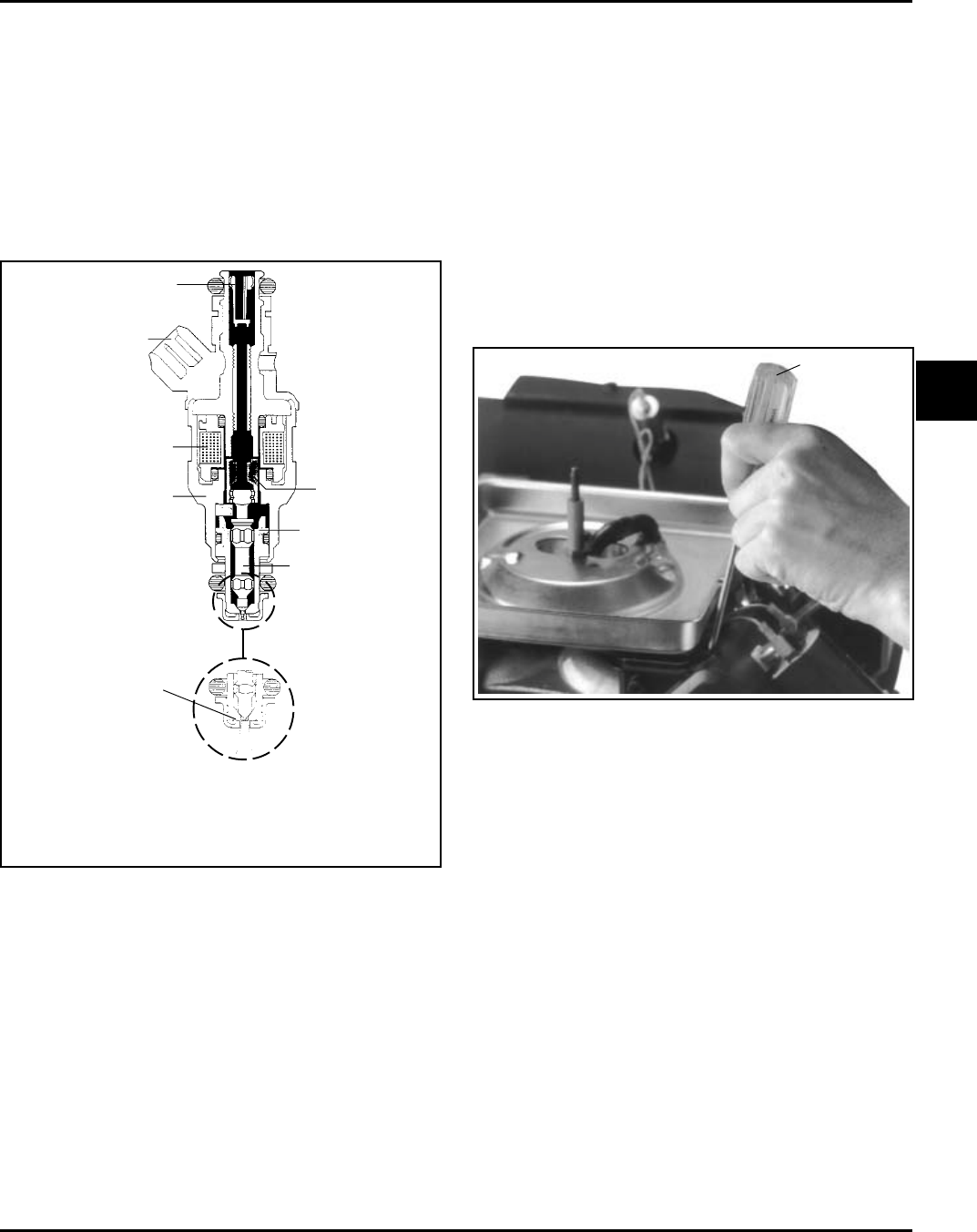

Figure 5B-18. Fuel Injector Details.

The injector is opened and closed once for each

crankshaft revolution, however only one-half the total

amount of fuel needed for one firing is injected during

each opening. The amount of fuel injected is controlled

by the ECU and determined by the length of time the

valve needle is held open, also referred to as the

“injection duration” or “pulse width”. It may vary in

length from 1.5-8 milliseconds depending on the speed

and load requirements of the engine.

Figure 5B-19. Checking Injectors.

3. Disconnect the electrical connector from an

injector and listen for a change in idle

performance (only running on one cylinder) or a

change in injector noise or vibration.

If an injector is not operating, it can indicate either a

bad injector, or a wiring/electrical connection problem.

Check as follows:

NOTE: Do not apply voltage to the fuel injector(s).

Excessive voltage will burn out the injector(s).

Do not ground the injector(s) with the ignition

“on”. Injector(s) will open/turn on if relay is

energized.

1. Disconnect the electrical connector from both

injectors. Plug the 12 volt test light (SPX Part No.

KO3217-6) in one connector.

1. Filter strainer in fuel supply

2. Electrical connection

3. Solenoid winding

4. Valve housing

Multi-Orifice

Director Plate with

Calibrated Opening

5. Armature

6. Valve body

7. Valve needle

Listen Here

1

2

3

4

5

6

7