5A.6

Section 5A

LPG Fuel Systems

LPG Carburetor - Reassembly

Impco Carburetor

1. Slide the venturi into the carburetor body, aligning

the position mark made prior to removal. Correctly

installed, the discharge holes should not be visible

from the top.

2. Secure with the venturi retaining screw. Torque

the screw to 4.0 N·m (36 in. lb.).

3. Install a new adapter gasket and mount the air

cleaner adapter onto the carburetor with the four

screws. Torque the screws to 4.0 N·m (36 in. lb.).

4. Install a new carburetor gasket onto the intake

manifold adapter, followed by the carburetor.

Install and finger tighten the mounting fasteners.

5. Connect the ‘‘Z’’ end of the throttle linkage and the

dampening spring to the throttle clamp bracket on

the throttle shaft. Attach the opposite end of

linkage and spring to the governor lever.

NOTE: The clamp brackets and stop collar

mounted on the throttle shaft should still

be in their original positions (See Figure

5A-2), and not require any readjustment/

resetting. Continue with steps 6 and 7. If

the mounted position of any one of these

was affected or changed, it will be

necessary to check and reset the

position of each before proceeding.

Follow the complete instructions listed

after step 7, then continue with steps 6

and 7.

6. Manually move the governor lever toward the

carburetor as far as it will go.

7. Check that the throttle plate is now fully open or

reposition the carburetor slightly on the mounting

screws so it is fully open. Torque the mounting

screws to 9.9 N·m (88 in. lb.).

Instructions for Checking/Positioning the Clamp

Brackets Mounted on the Throttle Shaft

Use only if the position or mounting of the clamp

bracket(s) has been disturbed. Figures show the

carburetor removed from the engine for clarity.

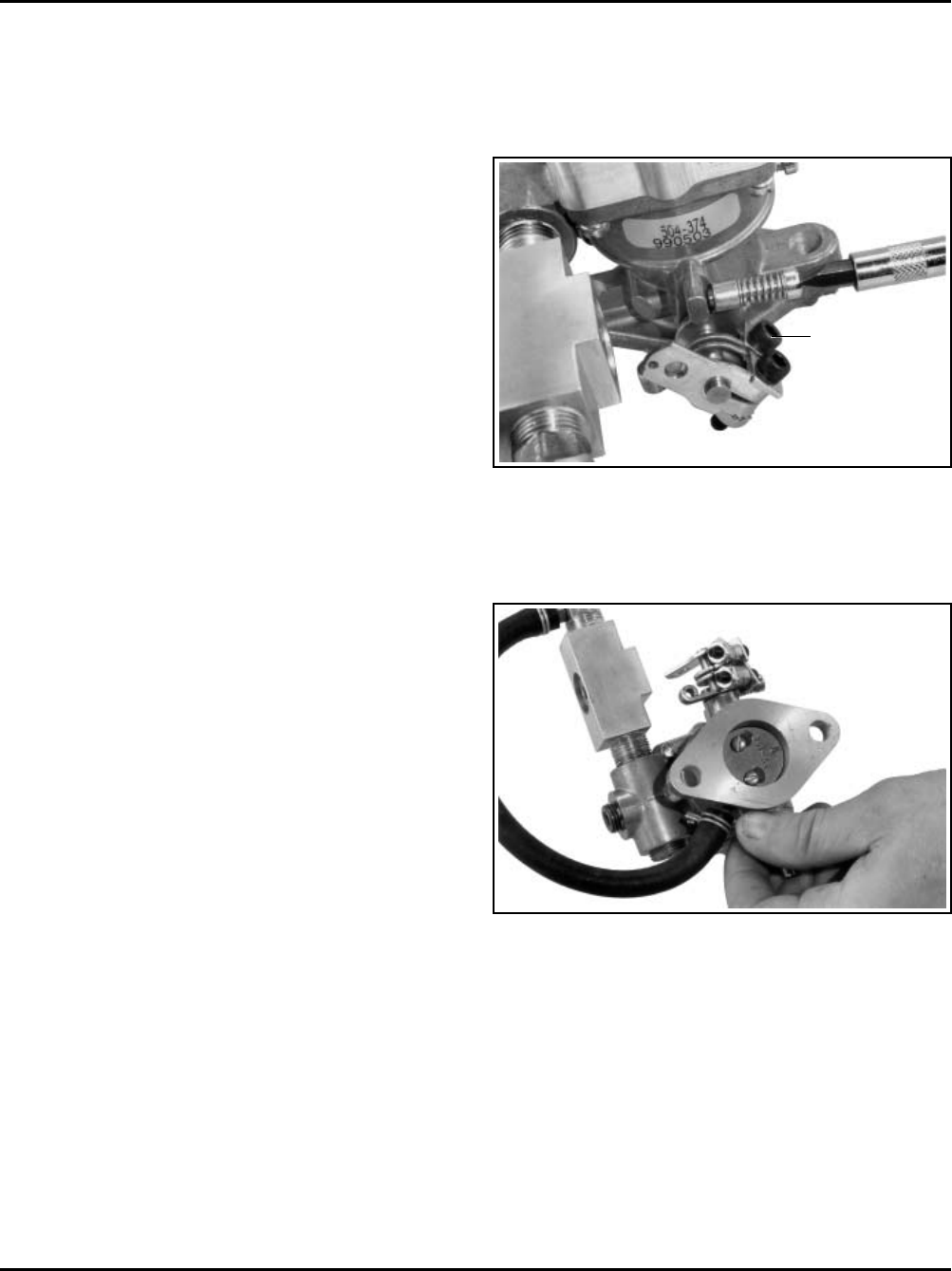

Figure 5A-8. Backing Off Idle Speed Screw.

2. Loosen the clamp bracket mounting screw, and

pivot the throttle shaft to fully close the throttle

plate. See Figure 5A-9.

Figure 5A-9. Closing Throttle Plate.

3. Hold the throttle plate closed and rotate the clamp

bracket until the end of the screw contacts the

stop. Insert a 0.025 mm (0.001 in.) feeler gauge

between the carburetor housing and the side of

the clamp bracket to set the endplay, then tighten

the mounting screw securely. See Figure 5A-10.

Idle Speed Clamp Bracket Position

1. Counting the number of turns, back the idle speed

adjustment screw off (counterclockwise), so only

1 to 1 1/2 of the threads are visible. See Figure

5A-8.

Idle Speed

Clamp

Bracket

Mounting

Screw