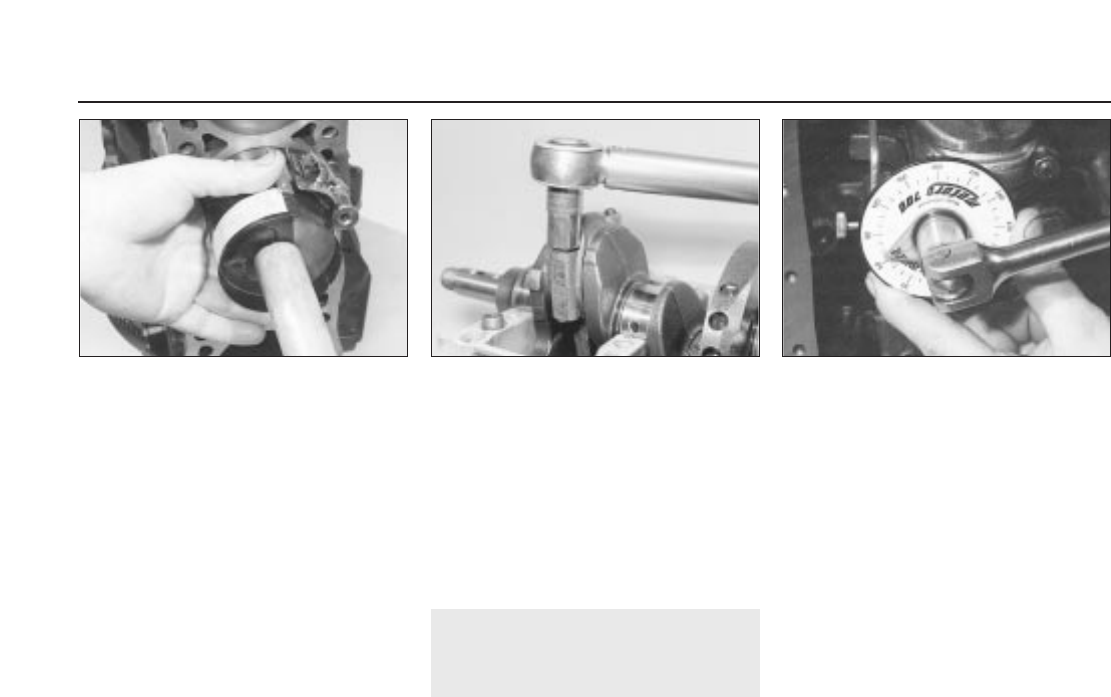

crankpin and both bearing shells. Taking care

not to mark the cylinder/liner bores, pull the

piston/connecting rod assembly down the

bore and onto the crankpin. Refit the big-end

bearing cap, tightening its retaining nuts

finger-tight at first. Note that the faces with

the identification marks must match (which

means that the bearing shell locating tabs

abut each other).

22 On XV, XW, XY and TU series engines,

tighten the bearing cap retaining nuts evenly

and progressively to the specified torque

setting (see illustration).

23 On XU series engines, tighten the bearing

cap retaining nuts evenly and progressively to

the Stage 1 torque setting. Fully slacken both

nuts, then tighten them to the Stage 2 torque

setting. Once both nuts have been tightened

to the Stage 2 setting, angle-tighten them

through the specified Stage 3 angle, using a

socket and extension bar. It is recommended

that an angle-measuring gauge is used during

this stage of the tightening, to ensure

accuracy (see illustration). If a gauge is not

available, use a dab of white paint to make

alignment marks between the nut and bearing

cap prior to tightening; the marks can then be

used to check that the nut has been rotated

sufficiently during tightening.

24 On XU and TU series engines, once the

bearing cap retaining nuts have been correctly

tightened, rotate the crankshaft. Check that it

turns freely; some stiffness is to be expected

if new components have been fitted, but there

should be no signs of binding or tight spots.

25 On XU and TU series engines, refit the

remaining three piston/connecting rod

assemblies in the same way.

26 On XV, XW and XY series engines,

continue the crankshaft refitting procedure

described in Section 13. On all other engines,

refit the cylinder head and oil pump as

described in Part B or C of this Chapter (as

applicable).

15 Engine - initial start-up after

overhaul

1 With the engine refitted in the vehicle,

double-check the engine oil and coolant

levels. Make a final check that everything has

been reconnected, and that there are no tools

or rags left in the engine compartment.

2 Remove the spark plugs. On models with a

distributor, disable the ignition system by

disconnecting the ignition HT coil lead from

the distributor cap, and earthing it on the

cylinder block. Use a jumper lead or similar

wire to make a good connection. On models

with a static (distributorless) ignition system,

disable the ignition system by disconnecting

the LT wiring connector from the ignition

module, referring to Chapter 5B for further

information.

3 Turn the engine on the starter until the oil

pressure warning light goes out. Refit the

spark plugs, and reconnect the spark plug

(HT) leads, referring to Chapter 1 for further

information. Reconnect any HT leads or wiring

which was disconnected in paragraph 2.

4 Start the engine, noting that this may take a

little longer than usual, due to the fuel system

components having been disturbed.

5 While the engine is idling, check for fuel,

water and oil leaks. Don’t be alarmed if there

are some odd smells and smoke from parts

getting hot and burning off oil deposits.

6 Assuming all is well, keep the engine idling

until hot water is felt circulating through the

top hose, then switch off the engine.

7 Check the ignition timing and the idle speed

settings (as appropriate), then switch the

engine off.

8 After a few minutes, recheck the oil and

coolant levels as described in Chapter 1, and

top-up as necessary.

9 On XV, XW and XY series engines, and XU

series engines with hexagon type cylinder

head bolts, it will be necessary to re-tighten

the head bolts after the engine has been run

up to normal working temperature then

switched off and allowed to cool (see Part A

and B of this Chapter, as applicable). On all

other engines, if they were tightened as

described, there is no need to re-tighten the

cylinder head bolts once the engine has first

run after reassembly.

10 If new pistons, rings or crankshaft

bearings have been fitted, the engine must be

treated as new, and run-in for the first 500

miles (800 km). Do not operate the engine at

full-throttle, or allow it to labour at low engine

speeds in any gear. It is recommended that

the oil and filter be changed at the end of this

period.

2D•24 Engine removal and overhaul procedures

14.19 Tap the piston into the bore using a

hammer handle

14.22 Tightening a big-end bearing cap

nut using a torque wrench . . .

14.23 . . . and further, on XU series

engines, through the specified angle using

an angle tightening gauge