21 Loosen the tensioner pulley retaining nut.

Rotate the pulley anti-clockwise to remove all

free play from the timing belt, then retighten

the nut.

22 Tension the belt as described in

paragraphs 14 to 19 of Section 7.

23 Refit the timing belt covers as described

in Section 6.

Crankshaft sprocket

24 Where removed, locate the Woodruff key

in the crankshaft end, then slide on the

flanged spacer, aligning its slot with the

Woodruff key.

25 Align the crankshaft sprocket slot with the

Woodruff key, and slide it onto the end of the

crankshaft.

26 Temporarily remove the locking pin from

the rear of the flywheel, then refit the

crankshaft sprocket retaining bolt and

washer. Tighten the bolt to the specified

torque, whilst preventing crankshaft rotation

using the method employed on removal. Refit

the locking pin to the rear of the flywheel.

27 Relocate the timing belt on the crankshaft

sprocket. Ensure that the “front run” of the

belt is taut - ie, ensure that any slack is on the

tensioner pulley side of the belt. Do not twist

the belt sharply while refitting it, and ensure

that the belt teeth are seated centrally in the

sprockets.

28 Loosen the tensioner pulley retaining nut.

Rotate the pulley anti-clockwise to remove all

free play from the timing belt, then retighten

the nut.

29 Tension the belt as described in

paragraphs 14 to 19 of Section 7.

30 Refit the timing belt covers as described

in Section 6.

Tensioner pulley

31 Refit the tensioner pulley to its mounting

stud, and fit the retaining nut.

32 Ensure that the “front run” of the belt is

taut - ie, ensure that any slack is on the pulley

side of the belt. Check that the belt is centrally

located on all its sprockets. Rotate the pulley

anti-clockwise to remove all free play from the

timing belt, then tighten the pulley retaining

nut securely.

33 Tension the belt as described in

paragraphs 14 to 19 of Section 7.

34 Refit the timing belt covers as described

in Section 6.

9 Camshaft oil seal - renewal

3

Note: If the camshaft oil seal is to be renewed

with the timing belt still in place, check first

that the belt is free from oil contamination.

(Renew the belt as a matter of course if signs

of oil contamination are found; see Section 7).

Cover the belt to protect it from oil

contamination while work is in progress.

Ensure that all traces of oil are removed from

the area before the belt is refitted.

1 Remove the camshaft sprocket as

described in Section 8.

2 Punch or drill two small holes opposite

each other in the oil seal. Screw a self-tapping

screw into each, and pull on the screws with

pliers to extract the seal.

3 Clean the seal housing, and polish off any

burrs or raised edges, which may have

caused the seal to fail in the first place.

4 Lubricate the lips of the new seal with clean

engine oil, and drive it into position until it

seats on its locating shoulder. Use a suitable

tubular drift, such as a socket, which bears

only on the hard outer edge of the seal. Take

care not to damage the seal lips during fitting.

Note that the seal lips should face inwards.

5 Refit the camshaft sprocket as described in

Section 8.

10 Camshaft and rocker arms -

removal, inspection and

refitting

4

General information

1 The rocker arm assembly is secured to the

top of the cylinder head by the cylinder head

bolts. Although in theory it is possible to undo

the head bolts and remove the rocker arm

assembly without removing the head, in

practice, this is not recommended. Once the

bolts have been removed, the head gasket will

be disturbed, and the gasket will almost

certainly leak or blow after refitting. For this

reason, removal of the rocker arm assembly

cannot be done without removing the cylinder

head and renewing the head gasket.

2 The camshaft is slid out of the right-hand

end of the cylinder head, and it therefore

cannot be removed without first removing the

cylinder head, due to a lack of clearance.

Removal

Rocker arm assembly

3 Remove the cylinder head as described in

Section 11.

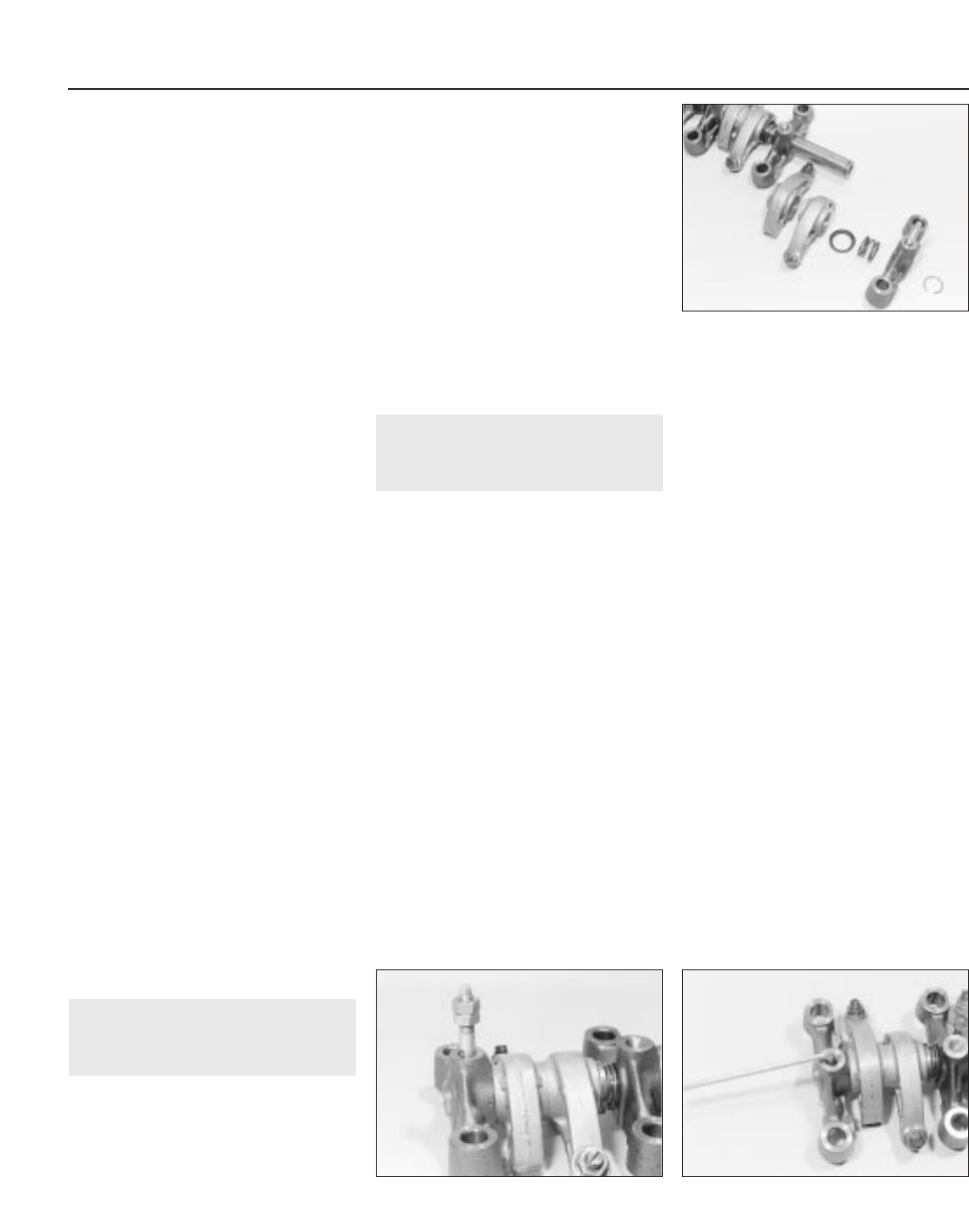

4 To dismantle the rocker arm assembly,

carefully prise off the circlip from the right-

hand end of the rocker shaft; retain the rocker

pedestal, to prevent it being sprung off the

end of the shaft. Slide the various

components off the end of the shaft, keeping

all components in their correct fitted order

(see illustration). Make a note of each

component’s correct fitted position and

orientation as it is removed, to ensure it is

fitted correctly on reassembly.

5 To separate the left-hand pedestal and

shaft, first unscrew the cylinder head cover

retaining stud from the top of the pedestal;

this can be achieved using a stud extractor, or

two nuts locked together. With the stud

removed, unscrew the grub screw from the

top of the pedestal, and withdraw the rocker

shaft (see illustrations).

Camshaft

6 Remove the cylinder head as described in

Section 11.

7 With the head on a bench, remove the

locking pin, then remove the camshaft

sprocket as described in paragraphs 6 and 7

of Section 8.

8 Unbolt the housing from the left-hand end

of the cylinder head, then undo the retaining

bolt, and remove the camshaft thrust fork

from the cylinder head (see illustration).

9 Using a large flat-bladed screwdriver,

carefully prise the oil seal out of the right-hand

end of the cylinder head, then slide out the

camshaft (see illustrations). Discard the seal

- a new one must be used on refitting.

Inspection

Rocker arm assembly

10 Examine the rocker arm bearing surfaces

2C•8 TU series engine in-car repair procedures

10.4 Remove the circlip, and slide the

components off the end of the rocker shaft

10.5a To remove the left-hand pedestal,

lock two nuts together and unscrew the

stud . . .

10.5b . . . then remove the grub screw