is available, it should be refitted to the

tensioned run of the belt. The reading should

now be between 42 and 46 units.

37 If the tension is not as specified, repeat

the tensioning operation.

38 Refit the belt covers and the crankshaft

pulley. Apply thread locking compound to the

crankshaft pulley bolt threads, and tighten the

bolt to the specified torque.

39 On completion, refit all disturbed

components, and tension the auxiliary

drivebelt, as described in Chapter 1.

5 Timing belt tensioner and

sprockets - removal,

inspection and refitting

3

Removal

Camshaft sprocket

1 Remove the timing belt as described in

Section 4.

2 Remove the locking pin from the camshaft

sprocket, slacken the sprocket retaining bolt

and remove it, along with its washer. To

prevent the camshaft rotating as the bolt is

slackened, restrain the sprocket with a

suitable tool through the holes in the sprocket

face (see Tool Tip). Do not attempt to use the

sprocket locking pin to prevent the sprocket

from rotating whilst the bolt is slackened.

3 With the retaining bolt removed, slide the

sprocket off the end of the camshaft. If the

locating peg is a loose fit in the rear of the

sprocket, remove it for safe-keeping. Examine

the camshaft oil seal for signs of oil leakage

and, if necessary, renew it as described in

Section 6.

Crankshaft sprocket

4 Remove the timing belt as described in

Section 4.

5 Slide the sprocket off the end of the

crankshaft. Remove the Woodruff key from

the crankshaft, and store it with the sprocket

for safe-keeping. Where necessary, also slide

the spacer (where fitted) off the end of the

crankshaft.

6 Examine the crankshaft oil seal for signs of

oil leakage and, if necessary, renew it as

described in Section 12.

Tensioner assembly (models with

spring-loaded tensioner)

7 Remove the timing belt as described in

Section 4.

8 Undo the two bolts at the front and single

nut at the rear and withdraw the spring

housing spring and tensioner pulley. Take

care to keep the spring under control as the

bolts are undone to prevent it flying out.

Tensioner assembly (models with

eccentric roller tensioner)

9 Remove the timing belt as described in

Section 4.

10 Slacken and remove the timing belt

tensioner pulley retaining bolt, and slide the

pulley off its mounting stud. Examine the

mounting stud for signs of damage and if

necessary, renew it.

Inspection

11 Clean the camshaft/crankshaft sprockets

thoroughly, and renew any that show signs of

wear, damage or cracks.

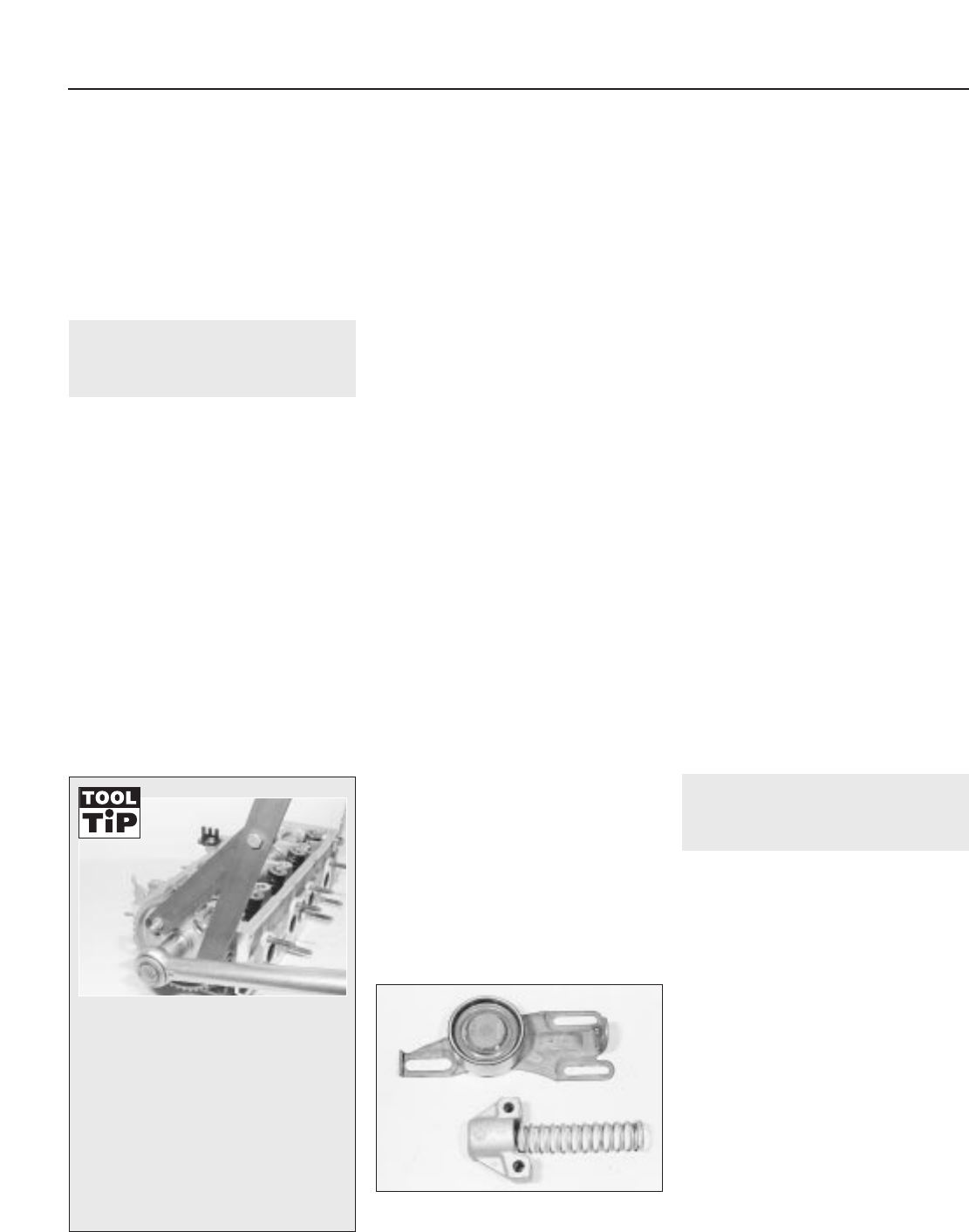

12 Clean the tensioner assembly, but do not

use any strong solvent which may enter the

pulley bearing. Check that the pulley rotates

freely on the backplate, with no sign of

stiffness or free play (see illustration). Renew

the assembly if there is any doubt about its

condition, or if there are any obvious signs of

wear or damage.

Refitting

Camshaft sprocket

13 Refit the locating peg (where removed) to

the rear of the sprocket. Locate the sprocket

on the end of the camshaft, ensuring that the

locating peg is correctly engaged with the

cut-out in the camshaft end.

14 Refit the sprocket retaining bolt and

washer, and tighten it to the specified torque.

Retain the sprocket with the tool used on

removal. Note that on early models the

sprocket is secured with an M12 bolt whereas

this has been reduced to M10 on later

engines. Ensure that the correct torque

wrench setting is used according to bolt type.

15 Realign the hole in the camshaft sprocket

with the corresponding hole in the cylinder

head, and refit the locking pin. Check that the

crankshaft pulley locking pin is still in position.

16 Refit the timing belt (Section 4).

Crankshaft sprocket

17 Slide the spacer (where fitted) into

position, taking great care not to damage the

crankshaft oil seal, and refit the Woodruff key

to its slot in the crankshaft end.

18 Slide on the crankshaft sprocket, aligning

its slot with the Woodruff key.

19 Refit the timing belt (Section 4).

Tensioner assembly (models with

spring-loaded tensioner)

20 Assemble the tensioner spring, spring

housing and pulley then locate the assembly

on the engine.

21 Fit the front bolts and rear locknut finger

tight only. Use a spanner on the square end of

the tensioner cam spindle to turn the cam to

the horizontal position and so compress the

tensioner spring. Tighten the cam locknut.

22 Refit the timing belt (Section 4).

Tensioner assembly (models with

eccentric roller tensioner)

23 Refit the tensioner pulley to its mounting

stud, and fit the retaining bolt.

24 Refit the timing belt (Section 4).

6 Camshaft oil seal - renewal

3

1 Remove the camshaft sprocket as

described in Section 5. Remove the rear cover

plate behind the sprocket.

2 Punch or drill two small holes opposite

each other in the oil seal. Screw a self-tapping

screw into each, and pull on the screws with

pliers to extract the seal.

3 Clean the seal housing, and polish off any

burrs or raised edges, which may have

caused the seal to fail in the first place.

4 Lubricate the lips of the new seal with clean

engine oil, and drive it into position until it

seats on its locating shoulder. Use a suitable

tubular drift, such as a socket, which bears

only on the hard outer edge of the seal. Take

care not to damage the seal lips during fitting.

Note that the seal lips should face inwards.

5 Refit the sprocket rear cover plate, locate it

correctly with a 10 mm dowel and tighten its

fastenings.

6 Refit the camshaft sprocket as described in

Section 5.

2B•6 XU series engine in-car repair procedures

5.12 Spring loaded timing belt tensioner

components

To make a camshaft sprocket holding

tool, obtain two lengths of steel strip

about 6 mm thick by 30 mm wide or

similar, one 600 mm long, the other 200

mm long (all dimensions approximate).

Bolt the two strips together to form a

forked end, leaving the bolt slack so

that the shorter strip can pivot freely. At

the end of each ‘prong’ of the fork,

secure a bolt with a nut and a locknut,

to act as the fulcrums; these will engage

with the cut-outs in the sprocket, and

should protrude by about 30 mm