21 If warpage of the cylinder head gasket

surface is suspected, use a straight-edge to

check it for distortion. Refer to Part D of this

Chapter if necessary.

22 Check the condition of the cylinder head

bolts, and particularly their threads, whenever

they are removed. Wash the bolts in suitable

solvent, and wipe them dry. Check each for

any sign of visible wear or damage, renewing

any bolt if necessary. Measure the length of

each bolt, to check for stretching (although

this is not a conclusive test, in the event that

all ten bolts have stretched by the same

amount). Although Peugeot do not actually

specify that the bolts must be renewed, it is

strongly recommended that the bolts should

be renewed as a complete set whenever they

are disturbed.

23 Note that as from early 1987, the cylinder

head bolts are of No 55 Torx type and 8 mm

thick washers are fitted to these bolts,

whereas 3 mm thick washers fitted to the

earlier type hexagon head bolts (see

illustration). The spacer fitted to the bolt at

the timing belt end is 25 mm thick, (previously

23 mm), and is identified by a groove around

its perimeter. A modified cylinder head gasket

is also fitted to engines with Torx type cylinder

head bolts, so it is important to quote the

engine number accurately when obtaining a

new one.

Refitting

24 Commence refitting by fitting the dowels to

the cylinder block. Keep the flywheel-end dowel

raised by inserting a 5 mm punch or large nail

through the hole in the front of the block (see

illustration). Remove the liner clamps.

25 Fit the new gasket, dry, with the tab at the

flywheel end. Lower the cylinder head into

position, making sure that it mates with the

dowels. Remove the punch or nail.

26 Fit the cylinder head bolts, their threads

clean and lightly oiled. Remember to fit the

spacer to the bolt at the timing belt end. When

fitting the Torx type cylinder head bolts, apply

a little molybdenum disulphide grease to their

heads, and to the contact surface of their

heads.

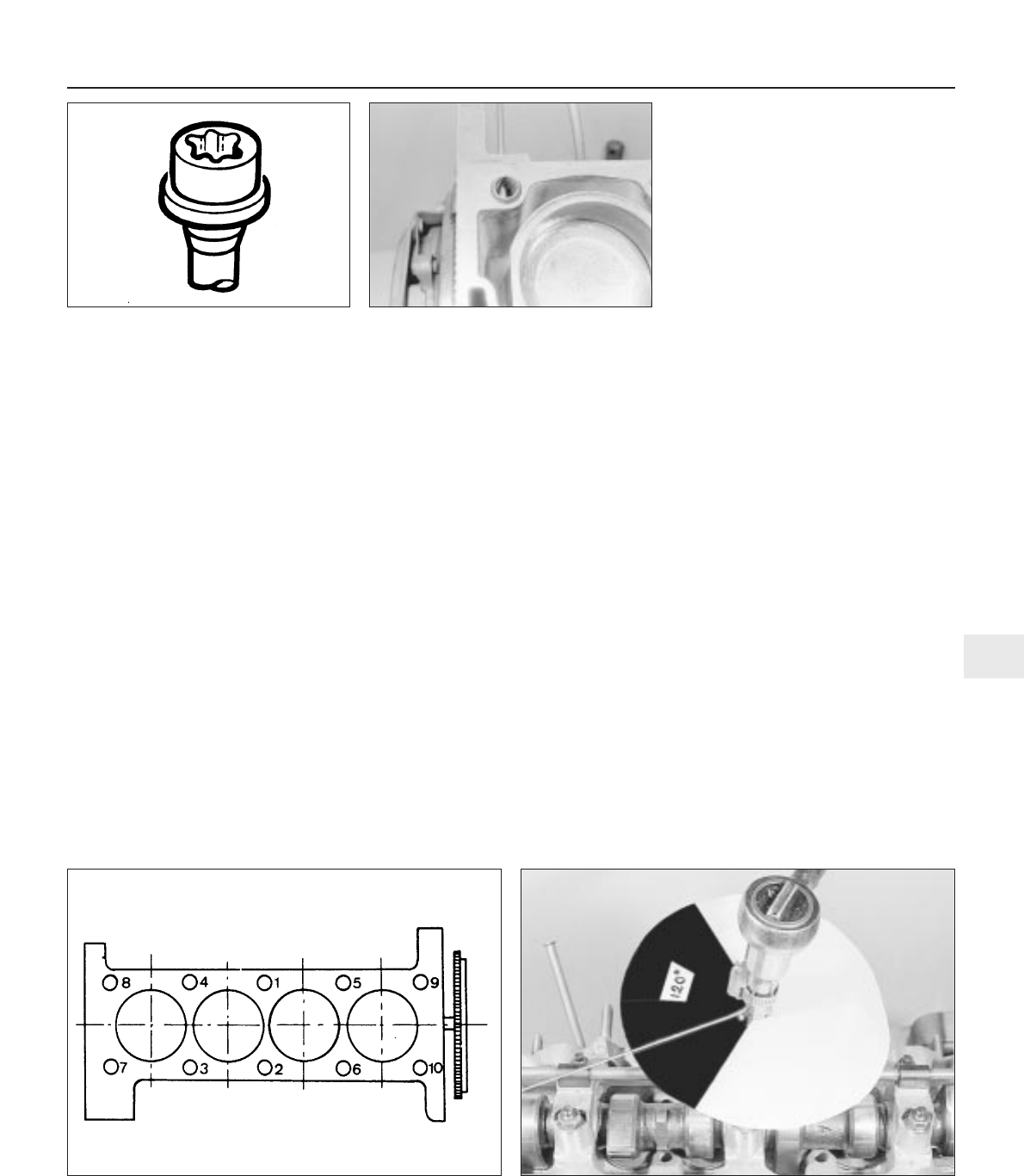

27 Progressively tighten the bolts in the order

shown to the Stage 1 specified torque setting

(see illustration). Note that the torque

settings are different for the two cylinder head

bolt types; ensure that the correct setting is

being used according to bolt type.

28 Raise the engine slightly and refit the two

bolts which secure the right-hand mounting

bracket to the cylinder head. Tighten these

bolts and slacken the one which holds the

same bracket to the engine block. Lower the

engine and tighten the right-hand mounting nut

and the lower mounting rubber nut and bolt.

Engines with hexagon head type

cylinder head bolts

29 Slacken cylinder head bolt No 1, then

immediately retighten it to the Stage 2

specified torque. Tighten further by the angle

specified for Stage 3 using a socket and

extension bar. It is recommended that an

angle-measuring gauge is used during this

stage of tightening, to ensure accuracy (see

illustration). Repeat for all the bolts, following

the tightening sequence.

30 Check the valve clearances and adjust, if

necessary (see Section 2).

31 Refit the remaining components in the

reverse order of removal. Make sure that the

correct inlet manifold gasket is fitted. A gasket

for carburettor versions is included in the

gasket overhaul set which is not the same as

the one for fuel injection models.

32 Refill and bleed the cooling system

(Chapter 1).

33 Start the engine and warm it up until the

cooling fan cuts in, then switch off and allow it

to cool for at least two hours.

34 Retighten the cylinder head bolts, as

described in paragraph 29, then recheck the

valve clearances.

35 If a new timing belt has been fitted, refer

to Section 4 and retension it if necessary.

36 Tighten the engine mounting bracket bolt.

Engines with Torx type cylinder head

bolts

37 Fully slacken all the head bolts, working in

the reverse of the tightening sequence. Once

the bolts are loose, tighten all bolts to their

Stage 2 specified torque setting, again

following the specified sequence.

38 With all the bolts tightened to their Stage 2

setting, working again in the specified

sequence, angle-tighten the bolts through the

specified Stage 3 angle, using a socket and

extension bar. It is recommended that an

angle-measuring gauge is used during this

stage of tightening, to ensure accuracy. Note

that no further tightening of the Torx type head

bolts is necessary.

XU series engine in-car repair procedures 2B•9

2B

8.23 Torx type cylinder head bolts fitted to

later models

8.24 Using a nail to hold the cylinder block

dowel in the raised position

8.27 Cylinder head bolt tightening sequence 8.29 Home-made torque angle measuring gauge. Disc is fixed

and pointer rotates