18 Disconnect the wire for the pad wear

warning light.

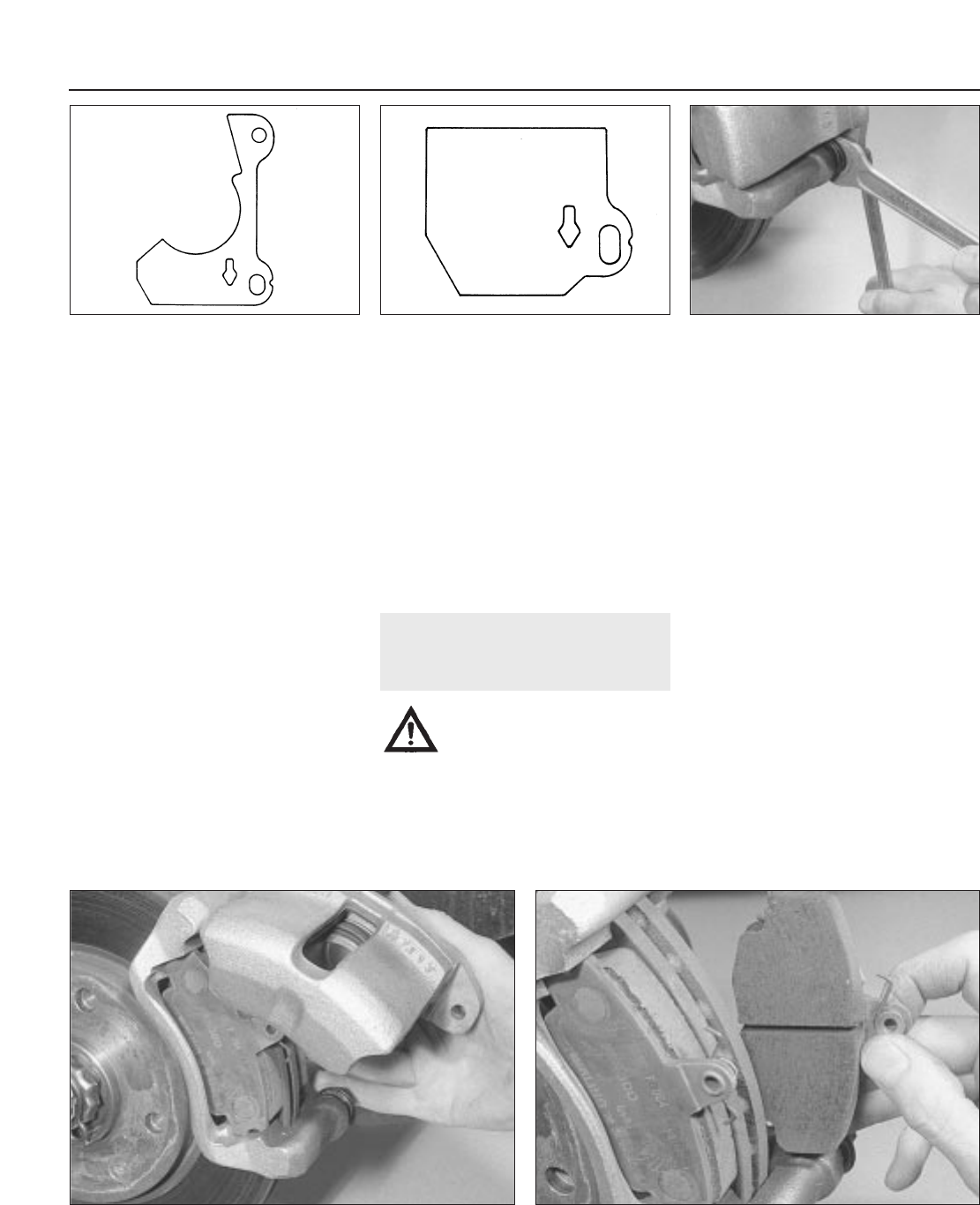

19 Hold the lower guide stationary with one

spanner, then unscrew the bolt (see

illustration).

20 Swivel the caliper upwards, then withdraw

the two brake pads from the caliper bracket

(see illustrations).

21 Clean and check the caliper, as described

in paragraph 7.

22 Push the piston fully into the cylinder.

23 Clean the backs of the pads, and apply a

little anti-squeal brake grease. Refit the inner

pad (with the pad wear warning wire), then the

outer pad.

24 Lower the caliper. Apply locking fluid to

the lower guide bolt, insert it, and tighten to

the specified torque while holding the guide

stationary with another spanner.

25 Reconnect the pad wear warning light

wire.

All calipers

26 Repeat the operations on the opposite

disc caliper.

27 Apply the footbrake several times to

position the pads against the discs.

28 Top-up the master cylinder reservoir to its

correct level.

29 Refit the roadwheels and lower the car to

the ground.

30 Note that if genuine Peugeot

replacements have been fitted, these pads

have a thin coating of abrasive material, which

cleans the disc during the initial applications

of the brakes. This coating also removes any

disc imperfections which would cause

steering vibration. After fitting these pads, the

brakes must be applied lightly and

intermittently for the first 3 miles (5 km), then

“bedded-in” for 120 miles (200 km), avoiding

heavy or prolonged braking wherever

possible.

5 Rear brake shoes - renewal

3

Warning: Brake shoes must be

renewed on both rear wheels at

the same time - never renew the

shoes on only one wheel, as

uneven braking may result. Also, the dust

created by wear of the shoes may contain

asbestos, which is a health hazard. Never

blow it out with compressed air, and don’t

inhale any of it. An approved filtering mask

should be worn when working on the

brakes. DO NOT use petrol or petroleum-

based solvents to clean brake parts; use

brake cleaner or methylated spirit only.

Note: The rear brake shoe assemblies may be

of either DBA Bendix or Girling manufacture,

according to model and year. The components

may vary in detail, but the principles described

in the following paragraphs are equally

applicable to both types. Make a careful note

of the fitted positions of all components before

dismantling.

1 Remove the relevant hub/drum as

described in Section 11.

2 Brush the dust and dirt from the shoes,

backplate and drum.

3 Note the position of each shoe and the

location of the return and steady springs (see

illustrations).

4 Unhook and remove the upper return spring

(see illustration).

5 Remove the steady springs using pliers to

depress the outer cups and turn them through

90° (see illustration). Remove the pins from

the backplate.

6 Move the serrated automatic adjuster lever

quadrant against spring tension (see

illustration), move the lever forwards and

release the strut from the top of the shoes

(DBA Bendix type only).

9•6 Braking system

4.14a Early type anti-squeal shim

(Girling caliper)

4.14b Later type anti-squeal shim

(Girling caliper)

4.19 Unscrewing the lower caliper guide

pin bolt (1.9 GTI)

4.20a Swivel the caliper upwards . . . 4.20b . . . then withdraw the two brake pads (1.9 GTI)