Refitting

6 Refitting is a reversal of removal, but note

that the nose of the unit must face forwards

and be inclined upwards at an angle of 22° to

the horizontal. Provided that the mounting

bracket is undamaged, this angle will

automatically be achieved. Finally bleed the

rear hydraulic circuit, as described in Section 2.

1.9 GTI models

General information

7 On 1.9 GTI models, the hydraulic circuit is

split diagonally and two compensators are

fitted. Each compensator is located in the rear

circuit near the rear wheel (see illustration).

They are of fixed calibration, and not

load-sensitive.

Removal

8 To minimise fluid loss, unscrew the master

cylinder reservoir filler cap and place a piece

of polythene over the filler neck. Secure the

polythene with an elastic band ensuring that

an airtight seal is obtained.

9 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and vehicle support”).

10 Unscrew the union nuts and disconnect

the rigid hydraulic lines from each end of the

unit while holding the unit on the flats

provided. Ease out the pipes and remove the

compensator from under the car.

11 Note that from December 1988, modified

compensators have been fitted. The modified

components can be identified by the letter on

the compensator body. Early components

have the identifying letter “F”, while later

components have the identifying letter “E”.

The later components can be used to replace

the early components, but both

compensators must be of the same type.

Refitting

12 Refitting is a reversal of removal. Bleed

the relevant hydraulic circuit, as described in

Section 2 on completion.

14 Vacuum servo unit - testing,

removal and refitting

3

Testing

1 With the engine switched off, depress the

brake pedal several times. The distance by

which the pedal moves should now alter over

all applications.

2 Depress the brake pedal fully and hold it

down then start the engine. The pedal should

be felt to move downward slightly.

3 Hold the pedal depressed with the engine

running, switch off the ignition and continue to

hold the pedal depressed for 30 seconds

during which period the pedal should neither

rise nor drop.

4 Start the engine whilst the brake pedal is

released, run it for a minute and switch off.

Give several applications of the brake pedal.

The pedal travel should decrease with each

application.

5 Failure of the brake pedal to act in the way

described will indicate a fault in the servo unit.

6 The servo unit should not be serviced or

overhauled beyond the operations described

in this Section and in the event of a fault

developing, renew the servo complete.

7 Periodically check the condition of the

vacuum hose and security of the clips.

8 Renew the hose if necessary.

9 If the servo hose right-angled non-return

valve is loose in its sealing grommet, or if the

grommet shows evidence of cracking or

perishing, renew it. Apply some hydraulic fluid

to the rubber to facilitate fitting.

Air filter renewal

10 Although not a specified operation, the air

filter through which the pushrod passes at the

rear of the servo can become clogged after a

high mileage. Disconnect the rod from the

pedal, cut the filter diagonally having slipped

the dust excluder off the rod. Fit the new filter.

Servo unit removal

11 Remove the master cylinder, as described

in Section 12. Disconnect the servo vacuum

hose.

12 Working inside the car, disconnect the

pushrod from the brake pedal; noting that it is

on the lower hole.

13 Unscrew the mounting nuts behind the

pedal bracket then withdraw the servo unit into

the engine compartment. Remove the gasket.

Servo unit refitting

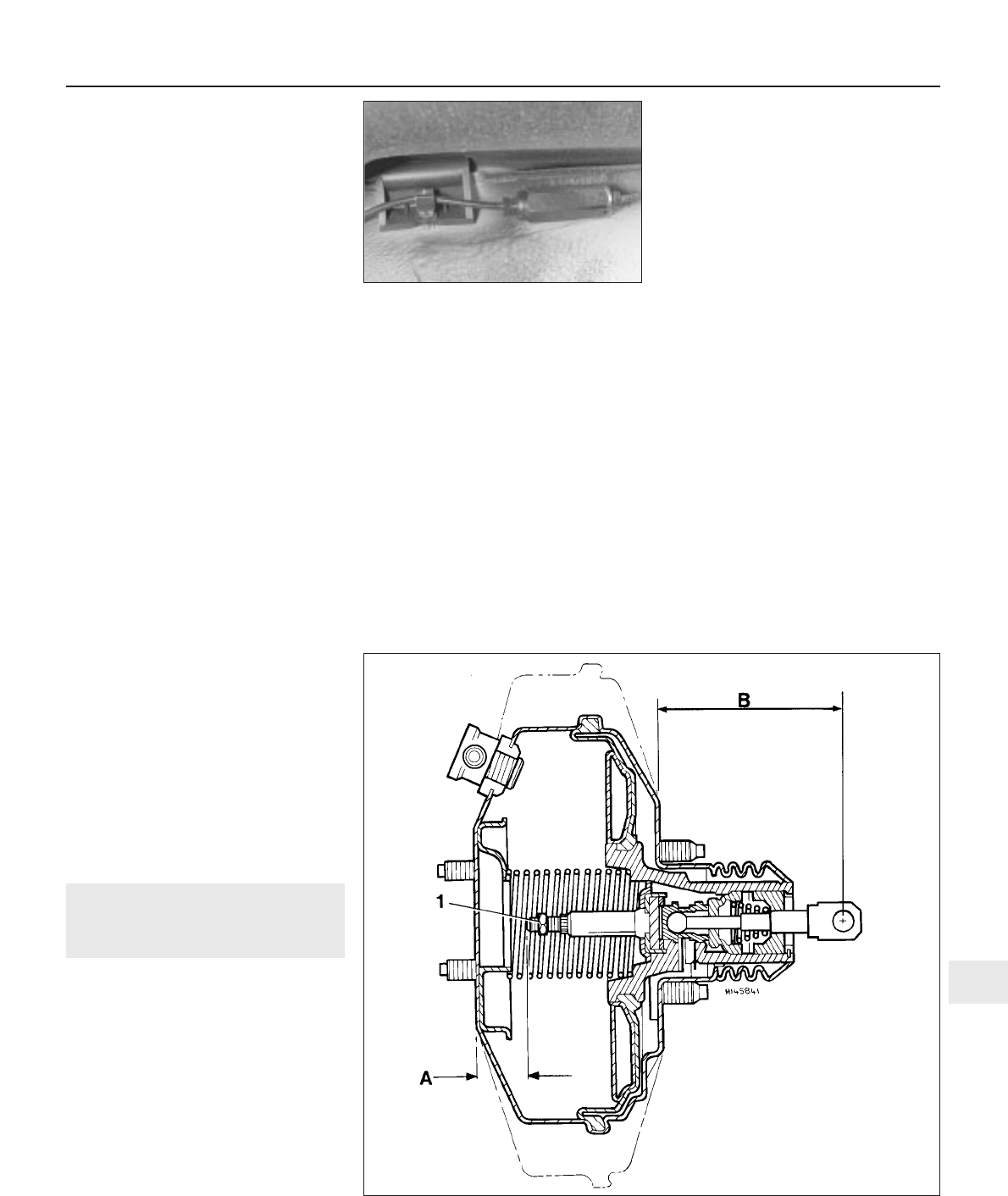

14 Before fitting a servo unit, check the

pushrod dimensions and adjust where

possible (see illustration).

15 Refitting is a reversal of removal, but fit a

new gasket and fully tighten the mounting

nuts. Note that the pushrod is fitted to the

lower hole of the two on the brake pedal. Refer

to Section 12 when refitting the master

cylinder. Finally, with the brake pedal released,

check that the clearance between the stop

light switch threaded shank and pedal is 3.5

mm. If necessary loosen the locknuts, adjust

the switch and tighten the locknuts.

Braking system 9•13

9

13.7 Rear brake compensator fitted to

1.9 GTI models

14.14 Cross-section of the vacuum

servo unit showing pushrod

adjustment dimensions

1 Adjustment screw

A = 22.2 to 22.4 mm

B = 86.5 to 89.5 mm