1 General information and

precautions

General information

The fuel system consists of a fuel tank

mounted under the rear of the car, a

mechanical fuel pump, and a single or twin

downdraught carburettor.

On manual transmission and early automatic

transmission models, the fuel pump is

operated by an eccentric on the camshaft, and

is mounted on the rear of the cylinder head. On

automatic transmission models manufactured

from November 1986, an electric fuel pump

submerged in the fuel tank is fitted instead of

the previous mechanical type. The two relays

which supply the pump are located on the side

of the heater. One relay incorporates a safety

feature, in that its primary windings are

short-circuited to earth via the engine oil

pressure switch. When the engine is stationary,

this relay will not operate the fuel pump, but as

soon as the engine is running it will supply

current to the pump. The other relay operates

in conjunction with the starter motor to operate

the fuel pump for starting.

A number of different Solex and Weber

carburettors may be encountered and their

type and engine applications are shown in the

Specifications. All carburettors are of the fixed

jet downdraught type with either manual or

automatic choke arrangements. XY8 engine

models utilise a twin carburettor configuration.

The air cleaner contains a disposable paper

filter element, and on certain models

incorporates a flap valve air temperature

control system; this allows cold air from the

outside of the car, and warm air from the

exhaust manifold, to enter the air cleaner in

the correct proportions.

Precautions

Warning: Petrol is extremely

flammable - great care must be

taken when working on any part

of the fuel system. Do not smoke

or allow any naked flames or uncovered

light bulbs near the work area. Note that

gas powered domestic appliances with pilot

flames, such as heaters, boilers and tumble

dryers, also present a fire hazard - bear this

in mind if you are working in an area where

such appliances are present. Always keep a

suitable fire extinguisher close to the work

area and familiarise yourself with its

operation before starting work. Wear eye

protection when working on fuel systems

and wash off any fuel spilt on bare skin

immediately with soap and water. Note that

fuel vapour is just as dangerous as liquid

fuel; a vessel that has just been emptied of

liquid fuel will still contain vapour and can

be potentially explosive. Petrol is a highly

dangerous and volatile liquid, and the

precautions necessary when handling it

cannot be overstressed.

Many of the operations described in this

Chapter involve the disconnection of fuel

lines, which may cause an amount of fuel

spillage. Before commencing work, refer to

the above Warning and the information in

“Safety first” at the beginning of this

manual.

When working with fuel system

components, pay particular attention to

cleanliness - dirt entering the fuel system

may cause blockages which will lead to

poor running.

2 Air cleaner assembly -

removal and refitting

1

Removal

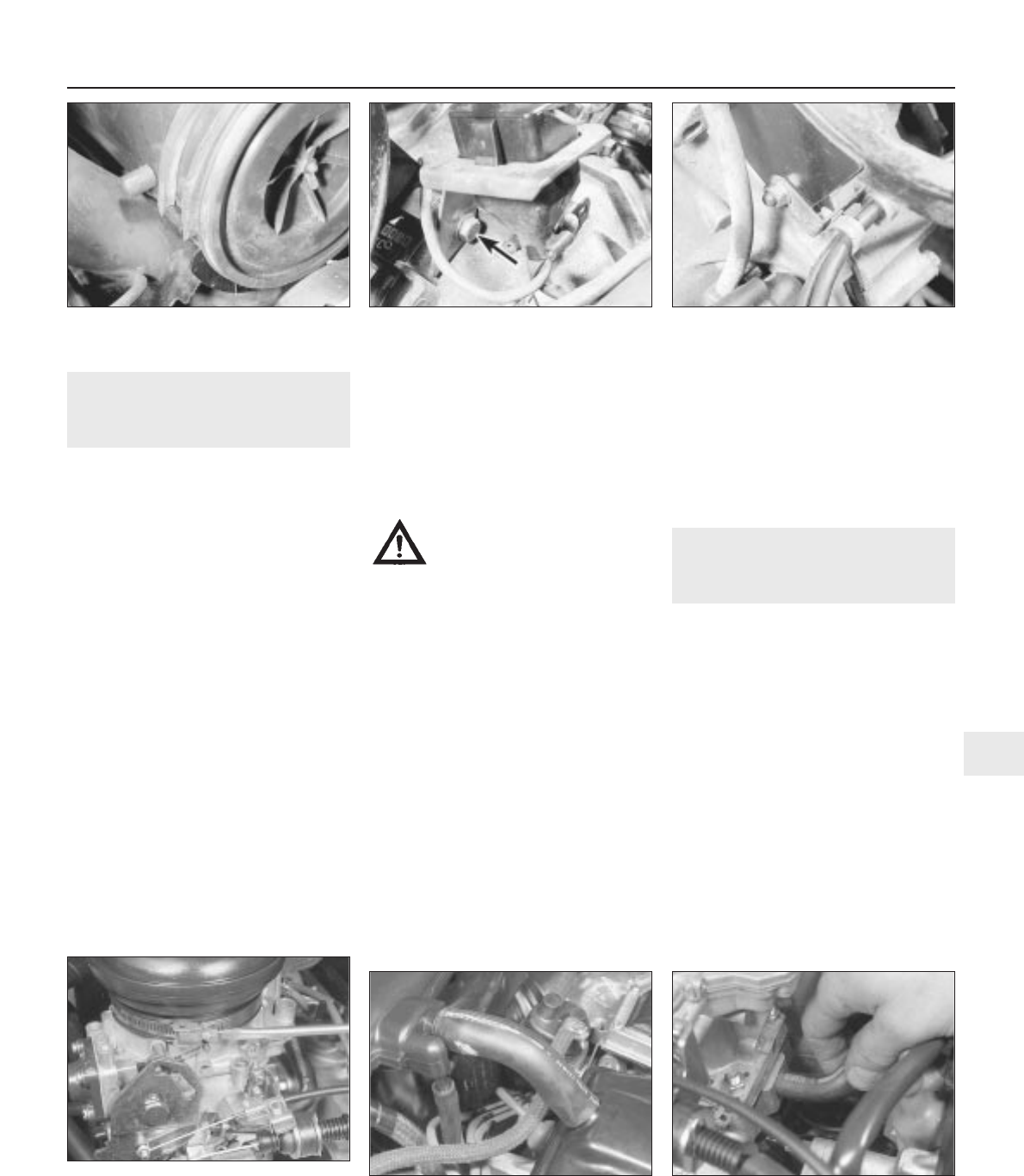

All engines except TU series

1 Disconnect the inlet and warm air hoses.

2 Release the rubber straps from the

mounting brackets (see illustration).

3 Lift the air cleaner from the brackets then

disconnect the outlet hose and where fitted,

the crankcase ventilation hose.

4 If necessary, unbolt the mounting brackets

- noting the location of the diagnostic socket

and cable retaining brackets (see

illustrations).

TU series engines

5 Loosen the screw and release the air

cleaner ducting from the carburettor (see

illustration).

6 Disconnect the crankcase ventilation hose

(see illustrations) from the valve cover and

inlet manifold.

Fuel system - carburettor engines 4A•3

4A

2.6b . . . and inlet manifold2.6a Disconnect the crankcase ventilation

hose from the valve cover . . .

2.5 On TU series engines, slacken the air

cleaner and release the ducting from the

carburettor

2.4b . . . and cable retaining bracket2.4a Air cleaner mounting bracket bolt

(arrowed) . . .

2.2 On all engines except TU series,

release the air cleaner rubber straps from

the mounting brackets