5 Examine the pump rotors and body for

signs of wear ridges and scoring. If worn, the

complete pump assembly must be renewed.

6 Examine the relief valve piston for signs of

wear or damage, and renew if necessary. The

condition of the relief valve spring can only be

measured by comparing it with a new one; if

there is any doubt about its condition, it

should also be renewed. Both the piston and

spring are available individually.

7 Thoroughly clean the oil pump strainer with

a suitable solvent, and check it for signs of

clogging or splitting. If the strainer is

damaged, the strainer and cover assembly

must be renewed.

8 Locate the relief valve spring, piston and

(where fitted) the guide pin in the strainer

cover, then refit the cover to the pump body.

Align the relief valve piston with its bore in the

pump. Refit the cover retaining bolts,

tightening them securely.

Refitting

9 Ensure that the locating dowel is in

position, then engage the pump sprocket with

its drive chain. Locate the pump on its dowel,

and refit the pump retaining bolts, tightening

them to the specified torque setting.

10 Refit the sump as described in Section 12.

14 Crankshaft oil seals -

renewal

3

Right-hand oil seal

1 Remove the crankshaft sprocket and

flanged spacer as described in Section 8.

Secure the timing belt clear of the working

area, so that it cannot be contaminated with

oil. Make a note of the correct fitted depth of

the seal in its housing.

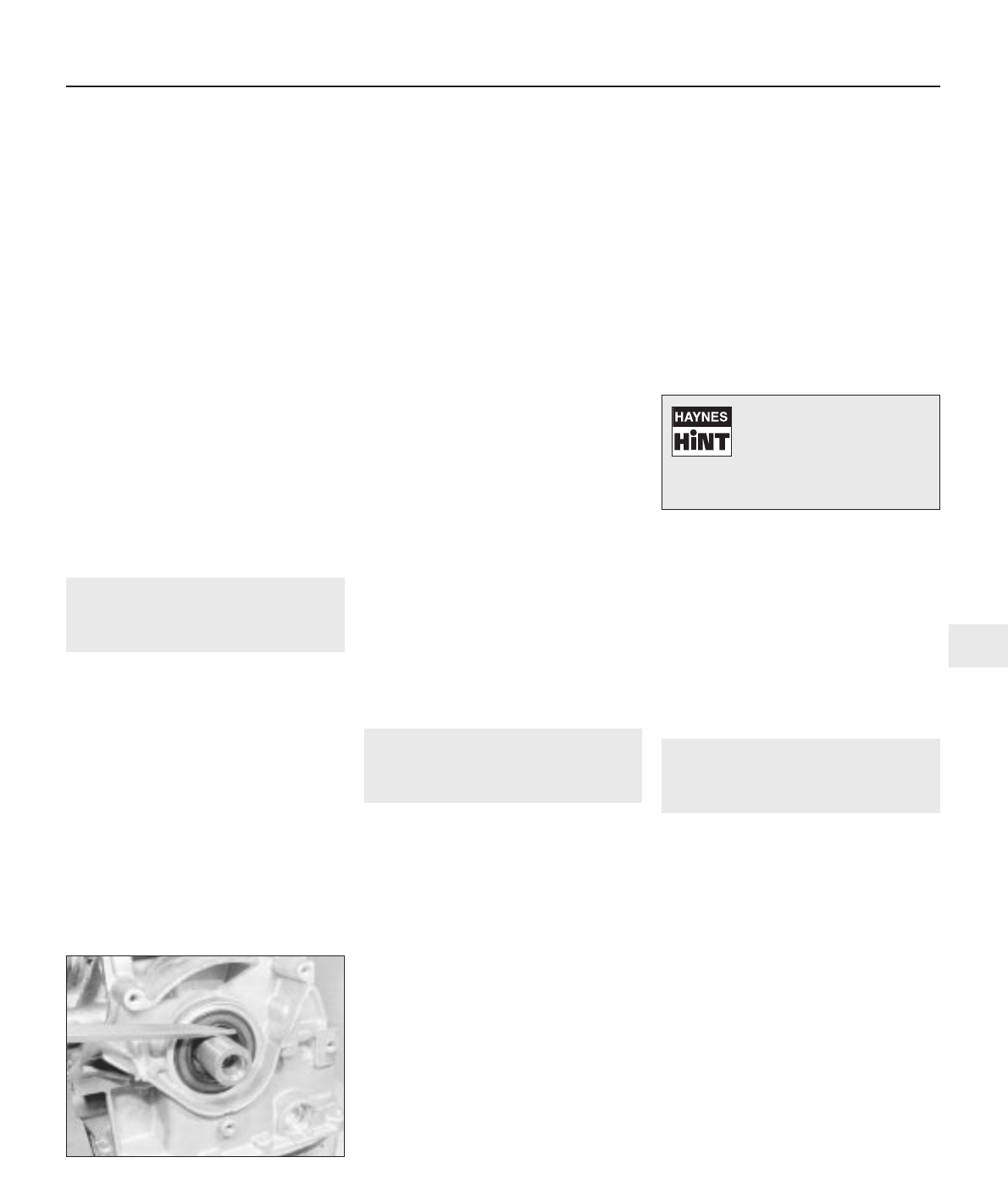

2 Punch or drill two small holes opposite

each other in the seal. Screw a self-tapping

screw into each, and pull on the screws with

pliers to extract the seal. Alternatively, the seal

can be levered out of position using a suitable

flat-bladed screwdriver, taking great care not

to damage the crankshaft shoulder or seal

housing (see illustration).

3 Clean the seal housing, and polish off any

burrs or raised edges, which may have

caused the seal to fail in the first place.

4 Lubricate the lips of the new seal with clean

engine oil, and carefully locate the seal on the

end of crankshaft. Note that its sealing lip

must face inwards. Take care not to damage

the seal lips during fitting.

5 Using a suitable tubular drift (such as a

socket) which bears only on the hard outer

edge of the seal, tap the seal into position, to

the same depth in the housing as the original

was prior to removal. The inner face of the

seal must end up flush with the inner wall of

the crankcase.

6 Wash off any traces of oil, then refit the

crankshaft sprocket as described in Section

8.

Left-hand oil seal

7 Remove the flywheel as described in

Section 15.

8 Make a note of the correct fitted depth of

the seal in its housing. Punch or drill two small

holes opposite each other in the seal. Screw a

self-tapping screw into each, and pull on the

screws with pliers to extract the seal.

9 Clean the seal housing, and polish off any

burrs or raised edges, which may have

caused the seal to fail in the first place.

10 Lubricate the lips of the new seal with

clean engine oil, and carefully locate the seal

on the end of the crankshaft.

11 Using a suitable tubular drift, which bears

only on the hard outer edge of the seal, drive

the seal into position, to the same depth in the

housing as the original was prior to removal.

12 Wash off any traces of oil, then refit the

flywheel as described in Section 15.

15 Flywheel - removal,

inspection and refitting

4

Removal

1 Remove the transmission as described in

Chapter 7A, then remove the clutch assembly

as described in Chapter 6.

2 Prevent the flywheel from turning by locking

the ring gear teeth with a screwdriver or a

similar arrangement to that shown in

illustration 8.10. Alternatively, bolt a strap

between the flywheel and the cylinder

block/crankcase. Do not attempt to lock the

flywheel in position using the locking pin

described in Section 3.

3 Slacken and remove the flywheel retaining

bolts, and discard them; they must be

renewed whenever they are disturbed.

4 Remove the flywheel. Do not drop it, as it is

very heavy. If the locating dowel is a loose fit

in the crankshaft end, remove and store it with

the flywheel for safe-keeping.

Inspection

5 If the flywheel’s clutch mating surface is

deeply scored, cracked or otherwise

damaged, the flywheel must be renewed.

However, it may be possible to have it

surface-ground; seek the advice of a Peugeot

dealer or engine reconditioning specialist.

6 If the ring gear is badly worn or has missing

teeth, it must be renewed. This job is best left

to a Peugeot dealer or engine reconditioning

specialist. The temperature to which the new

ring gear must be heated for installation is

critical and, if not done accurately, the

hardness of the teeth will be destroyed.

Refitting

7 Clean the mating surfaces of the flywheel

and crankshaft. Remove any remaining

locking compound from the threads of the

crankshaft holes, using the correct-size tap, if

available.

8 If the new flywheel retaining bolts are not

supplied with their threads already pre-

coated, apply a suitable thread-locking

compound to the threads of each bolt.

9 Ensure that the locating dowel is in

position. Offer up the flywheel, locating it on

the dowel, and fit the new retaining bolts.

10 Lock the flywheel using the method

employed on dismantling, and tighten the

retaining bolts to the specified torque.

11 Refit the clutch as described in Chapter 6.

Remove the locking tool, and refit the

transmission as described in Chapter 7A.

16 Engine/transmission

mountings - inspection and

renewal

3

Inspection

1 If improved access is required, raise the

front of the car and support it securely on axle

stands (see “Jacking and vehicle support”).

2 Check the mounting rubber to see if it is

cracked, hardened or separated from the

metal at any point; renew the mounting if any

such damage or deterioration is evident.

3 Check that all the mounting’s fasteners are

securely tightened; use a torque wrench to

check if possible.

4 Using a large screwdriver or a crowbar,

check for wear in the mounting by carefully

levering against it to check for free play. Where

this is not possible, enlist the aid of an assistant

to move the engine/transmission back and

forth, or from side to side, while you watch the

mounting. While some free play is to be

expected even from new components,

excessive wear should be obvious. If excessive

free play is found, check first that the fasteners

are correctly secured, then renew any worn

components as described below.

TU series engine in-car repair procedures 2C•13

2C

14.2 Using a screwdriver to lever out the

crankshaft front oil seal

If a suitable tap is not

available, cut two slots into

the threads of one of the old

flywheel bolts and use the

bolt to remove the locking compound

from the threads.