be fitted, obtain a set of new Black (Class B)

upper bearing shells and new Blue (Class A)

lower bearing shells. On later (mid-1993 on)

engines where the modified bearing shells are

already fitted, the running clearance check can

be carried out using the original bearing shells,

although it is preferable to use a new set as

described above, since the results obtained

will be a lot more conclusive. Note that on

most models, all the bearing shells are plain

except those fitted to journals 2 and 4 which

are grooved. Some engines, however, may

have a grooved bearing shell fitted to the

upper (cylinder block) location of No 5 main

bearing. Fit the ladder, tighten the bolts to the

specified torque and carry out the running

clearance check.

TU series cast-iron block engines

35 The procedure is similar to that described

in paragraphs 20 to 33 except that all the

bearing shells are plain except those fitted to

journals 2 and 4 which are grooved.

Final crankshaft refitting

XV, XW and XY series engines

36 Due to the arrangement of the split

crankcase it is necessary to have the pistons,

and connecting rods in place in the block

before refitting the crankshaft. Carry out the

operations described in Section 14, then

proceed as follows.

37 Place the bearing shells in their locations

as described earlier. If new shells are being

fitted, ensure that all traces of protective

grease are cleaned off using paraffin. Wipe

dry the shells with a lint-free cloth. Liberally

lubricate each bearing shell in the cylinder

block/crankcase with clean engine oil.

38 Fit the semi-circular thrustwashers which

control crankshaft endfloat. The oil grooves of

the thrustwashers must be against the

machined face of the crankshaft (see

illustration).

39 Oil the shell bearings and lower the

crankshaft into position (see illustration).

40 Reconnect the connecting rods to the

crankshaft as described in Section 14.

41 Fit a new O-ring seal to the crankcase

flange and check that the locating dowels are

in position (see illustration).

42 Apply jointing compound to the flange.

43 Clean the recesses in the remaining

crankcase housing section and fit the main

bearing shells. Note that the grooved shells

are located in positions 2 and 4.

44 Locate the housing, taking care not to

displace the bearing shells.

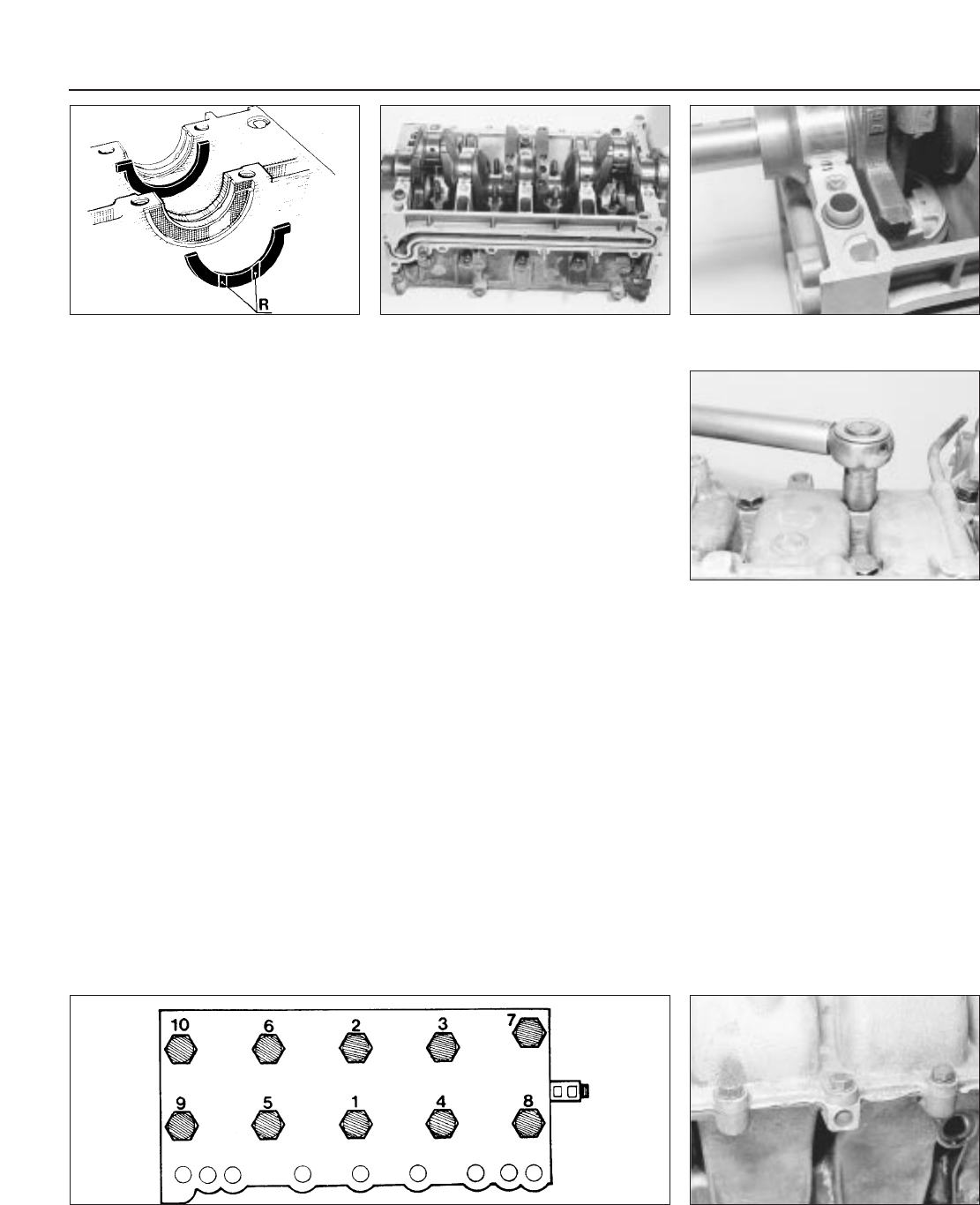

45 Screw in the ten main bearing/casing

bolts with flat washers; noting that the two

longer bolts are at the flywheel housing end

and the very long one at the crankshaft pulley

end on the oil pump side (see illustration).

46 Tighten the bolts in the sequence given in

two stages to the specified torque (see

illustration).

47 Now screw in and tighten the seven

casing flange bolts with their spring washers

(see illustration).

48 Fit a new crankshaft rear oil seal as

described in Part A of this Chapter.

49 Where removed, fit the cylinder head, as

described in Part A.

XU series engines

50 Carefully lift the crankshaft out of the

cylinder block once more.

51 Using a little grease, stick the upper

thrustwashers to each side of the No 2 main

bearing upper location. Ensure that the oilway

grooves on each thrustwasher face outwards

(away from the cylinder block) (see illustration).

52 Place the bearing shells in their locations

as described earlier. If new shells are being

fitted, ensure that all traces of protective

grease are cleaned off using paraffin. Wipe

dry the shells and connecting rods with a lint-

free cloth. Liberally lubricate each bearing

shell in the cylinder block/crankcase and cap

with clean engine oil.

2D•20 Engine removal and overhaul procedures

13.38 Crankshaft thrustwashers -

XV, XW and XY series engines

13.39 Lowering the crankshaft into place 13.41 Crankcase flange O-ring seal

13.46 Main bearing/casing bolt tightening sequence - XV, XW and XY series engines

R Oil grooves

13.45 Tightening the main bearing/casing

bolts

13.47 Refit the casing flange bolts and

washers