Reconnection

11 Ensure that the bush fitted to the centre of

the crankshaft is in good condition. Apply a

little Molykote G1 grease (available from your

Peugeot dealer) to the torque converter

centring pin. Do not apply too much,

otherwise there is a possibility of the grease

contaminating the torque converter.

12 Ensure that the locating dowels are

correctly positioned in the engine or

transmission.

13 Carefully offer the transmission to the

engine, until the locating dowels are engaged.

14 Refit the transmission housing-to-engine

bolts, ensuring that all the necessary brackets

are correctly positioned, and tighten them to

the specified torque setting.

15 Remove the torque converter retaining

strap installed prior to removal. Align the

torque converter threaded holes with the

retaining plate, and refit the three retaining

bolts.

16 Tighten the torque converter retaining

bolts to the specified torque setting, then refit

the driveplate lower cover.

17 Refit the starter motor, and securely

tighten its retaining bolts.

Refitting

18 Refit the engine/transmission to the

vehicle as described in paragraphs 59 to 63 of

Section 3.

19 The remainder of the refitting procedure is

a reversal of the removal sequence, noting the

following points:

a) Ensure that the wiring loom is correctly

routed, and retained by all the relevant

retaining clips; all connectors should be

correctly and securely reconnected.

b) Prior to refitting the driveshafts to the

transmission, renew the driveshaft oil

seals (see Chapter 7).

c) Ensure that all coolant hoses are correctly

reconnected, and securely retained by

their retaining clips.

d) Adjust the selector cable and kickdown

cable as described in Chapter 7B.

e) Adjust the throttle cable as described in

Chapter 4.

f) Refill the engine and transmission with

correct quantity and type of lubricant, as

described in Chapter 1.

g) Refill the cooling system as described in

Chapter 1.

5 Engine overhaul - preliminary

information

It is much easier to dismantle and work on

the engine if it is mounted on a portable

engine stand. These stands can often be hired

from a tool hire shop. Before the engine is

mounted on a stand, the flywheel/driveplate

should be removed so that the stand bolts

can be tightened into the end of the cylinder

block/crankcase.

If a stand is not available, it is possible to

dismantle the engine with it suitably

supported on a sturdy, workbench or on the

floor. Be careful not to tip or drop the engine

when working without a stand.

If you intend to obtain a reconditioned

engine, all ancillaries must be removed first, to

be transferred to the replacement engine (just

as they will if you are doing a complete engine

overhaul yourself). These components include

the following:

a) Alternator mounting brackets.

b) Engine mountings and brackets (Part A, B

or C of this Chapter).

c) The ignition system and HT components

including all sensors, distributor cap and

rotor arm, ignition module, HT leads and

spark plugs (Chapters 1 and 5).

d) Power steering pump and air conditioning

compressor brackets (where fitted).

e) Thermostat and housing, coolant pump,

coolant outlet chamber/elbow (Chapter

3).

f) Dipstick tube.

g) Carburettor/fuel system components

(Chapter 4).

h) All electrical switches and sensors.

i) Inlet and exhaust manifolds (Chapter 4).

j) Oil filter (Chapter 1).

k) Fuel pump - carburettor engines only

(Chapter 4).

l) Flywheel/driveplate (Part A, B or C of this

Chapter).

Note: When removing the external

components from the engine, pay close

attention to details that may be helpful or

important during refitting. Note the fitting

positions of gaskets, seals, washers, bolts and

other small items.

If you are obtaining a “short” engine

(cylinder block/crankcase, crankshaft, pistons

and connecting rods all assembled), then the

cylinder head, timing chain/belt (together with

tensioner, tensioner and idler pulleys and

covers) sump and oil pump will have to be

removed also.

If a complete overhaul is planned, the

engine can be dismantled in the order given

below, referring to Part A, B or C of this

Chapter unless otherwise stated.

a) Inlet and exhaust manifolds (Chapter 4).

b) Timing chain, sprockets, tensioner and oil

pump - XV, XW and XY series engines.

c) Timing belt, sprockets and tensioner - XU

and TU series engines.

d) Cylinder head.

e) Flywheel/driveplate - XU and TU series

engines.

f) Sump - XU and TU series engines.

g) Oil pump - XU and TU series engines.

h) Piston/connecting rod assemblies

(Section 7).

i) Crankshaft (Section 8).

6 Cylinder head - dismantling,

cleaning, inspection and

reassembly

3

Note: New and reconditioned cylinder heads

are available from the manufacturer, and from

engine overhaul specialists. Be aware that

some specialist tools are required for the

dismantling and inspection procedures, and

new components may not be readily available.

It may therefore be more practical and

economical for the home mechanic to

purchase a reconditioned head, rather than

dismantle, inspect and recondition the original

head.

Dismantling

1 Remove the cylinder head as described in

Part A, B or C of this Chapter (as applicable).

2 If not already done, remove the inlet and

exhaust manifolds with reference to the

relevant Part of Chapter 4.

3 Remove the camshaft, followers and shims

(as applicable) as described in Part A, B or C

of this Chapter.

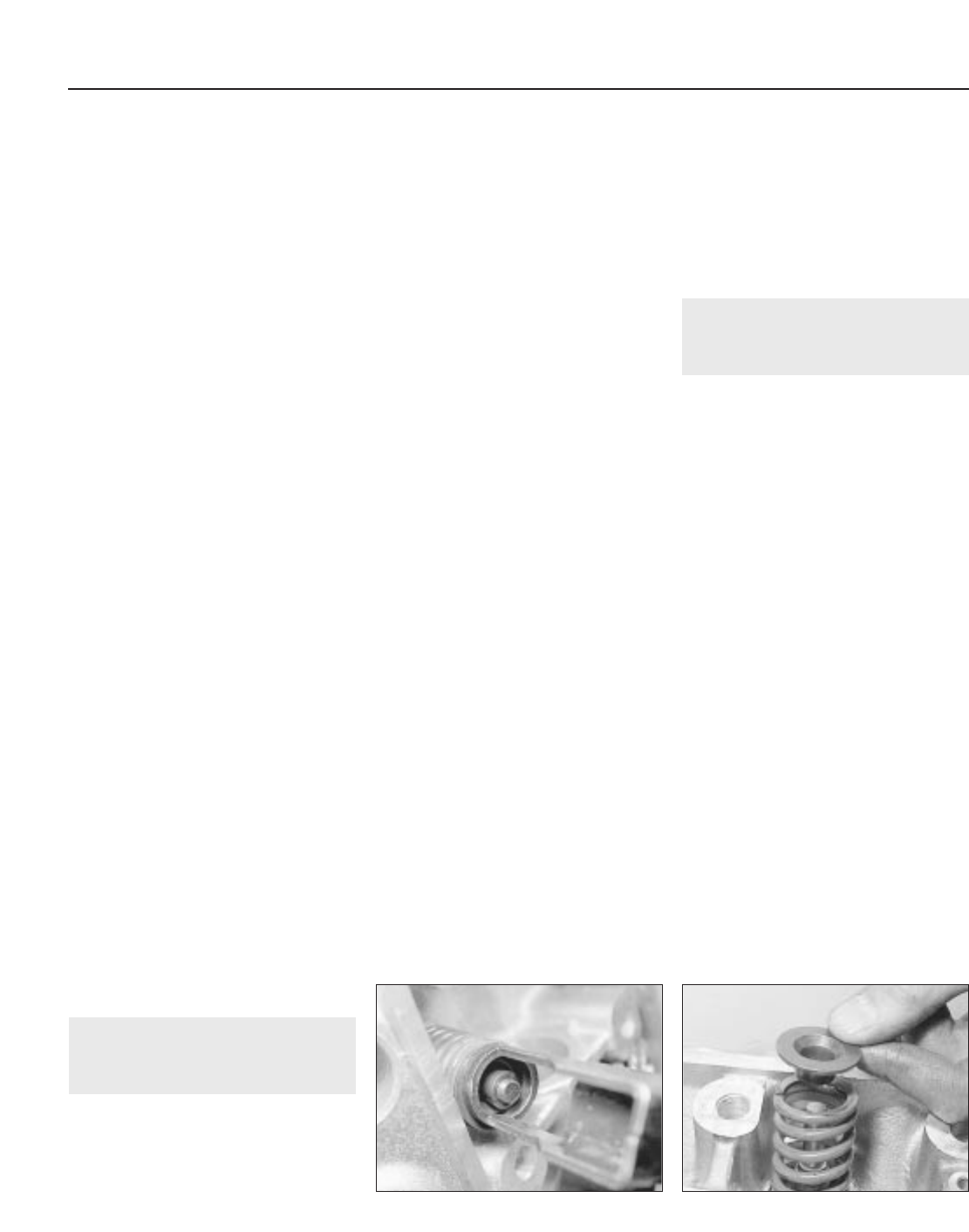

4 Using a valve spring compressor, compress

each valve spring in turn until the split collets

can be removed. Release the compressor,

and lift off the spring retainer, spring and

spring seat. Using a pair of pliers, carefully

extract the valve stem oil seal from the top of

the guide (see illustrations).

5 If, when the valve spring compressor is

screwed down, the spring retainer refuses to

free and expose the split collets, gently tap

the top of the tool, directly over the retainer,

with a light hammer. This will free the retainer.

6 Withdraw the valve through the combustion

chamber (see illustration).

2D•8 Engine removal and overhaul procedures

6.4a Compress the valve spring with a

compressor and remove the split collets . . .

6.4b . . . Release the compressor and

remove the spring retainer . . .