27 Before removing the crankshaft it is

advisable to check the endfloat as described

in paragraphs 6 and 7.

28 Unbolt and remove the crankshaft left-

and right-hand oil seal housings from each

end of the cylinder block, noting the correct

fitted locations of the locating dowels. If the

locating dowels are a loose fit, remove them

and store them with the housings for safe-

keeping.

29 Remove the oil pump drive chain, and

slide the drive sprocket off the end of the

crankshaft. Remove the Woodruff key, and

store it with the sprocket for safe-keeping.

30 The main bearing caps should be

numbered 1 to 5 from the transmission

(flywheel) end of the engine. If not, mark them

accordingly using a centre-punch or paint.

31 Unscrew and remove the main bearing

cap retaining bolts, and withdraw the caps.

Recover the lower main bearing shells, and

tape them to their respective caps for safe-

keeping.

32 Carefully lift out the crankshaft, taking

care not to displace the upper main bearing

shell.

33 Recover the upper bearing shells from the

cylinder block, and tape them to their

respective caps for safe-keeping. Remove the

thrustwasher halves from the side of No 2 main

bearing, and store them with the bearing cap.

Inspection

34 Clean the crankshaft using paraffin or a

suitable solvent, and dry it, preferably with

compressed air if available. Be sure to clean

the oil holes with a pipe cleaner or similar

probe, to ensure that they are not obstructed.

Warning: Wear eye protection

when using compressed air!

35 Check the main and big-end bearing

journals for uneven wear, scoring, pitting and

cracking.

36 Big-end bearing wear is accompanied by

distinct metallic knocking when the engine is

running (particularly noticeable when the

engine is pulling from low speed) and some

loss of oil pressure.

37 Main bearing wear is accompanied by

severe engine vibration and rumble - getting

progressively worse as engine speed

increases - and again by loss of oil pressure.

38 Check the bearing journal for roughness

by running a finger lightly over the bearing

surface. Any roughness (which will be

accompanied by obvious bearing wear)

indicates that the crankshaft requires

regrinding (where possible) or renewal.

39 If the crankshaft has been reground,

check for burrs around the crankshaft oil

holes (the holes are usually chamfered, so

burrs should not be a problem unless

regrinding has been carried out carelessly).

Remove any burrs with a fine file or scraper,

and thoroughly clean the oil holes as

described previously.

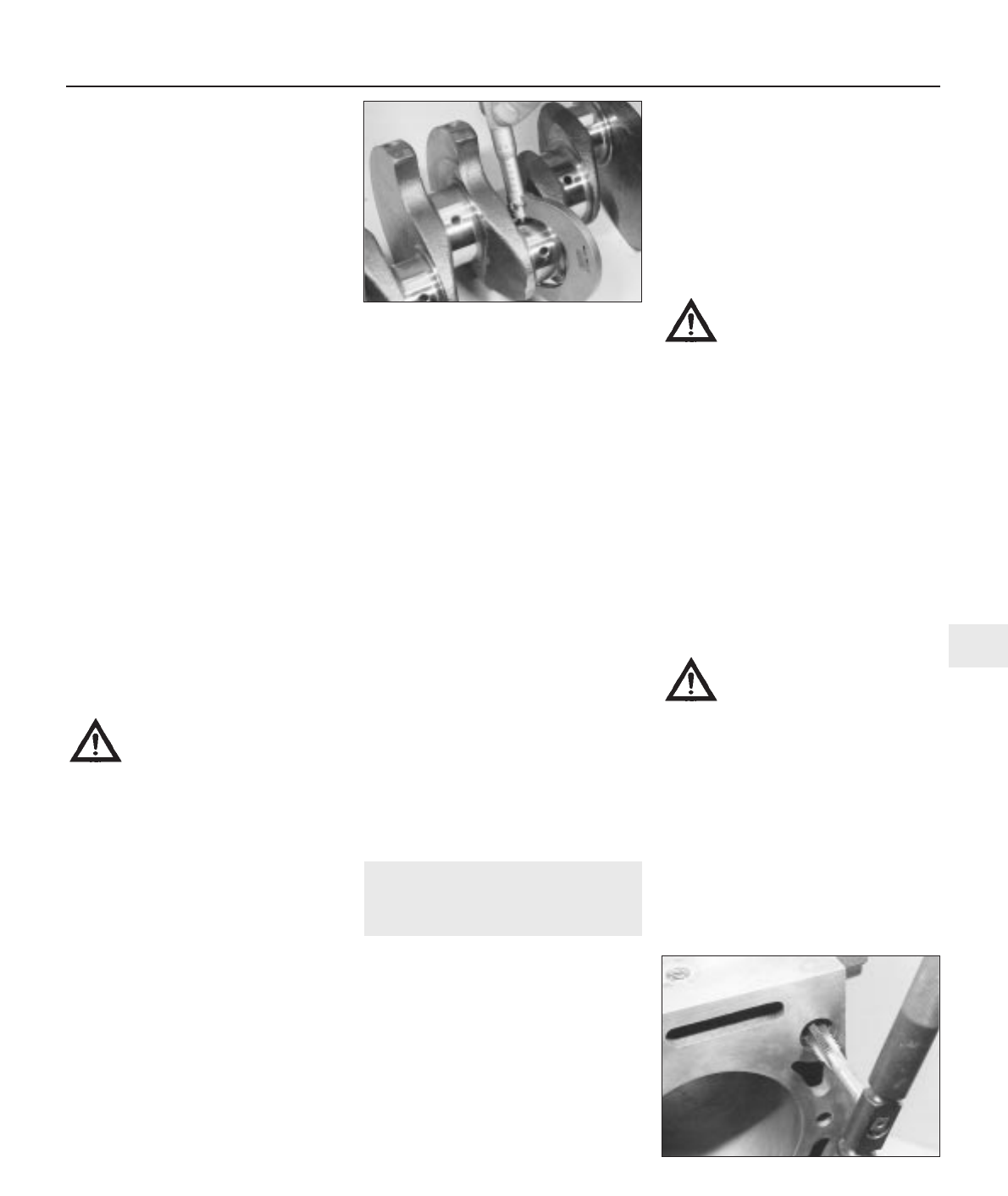

40 Using a micrometer, measure the

diameter of the main and big-end bearing

journals, and compare the results with the

Specifications (see illustration). By

measuring the diameter at a number of points

around each journal’s circumference, you will

be able to determine whether or not the

journal is out-of-round. Take the

measurement at each end of the journal, near

the webs, to determine if the journal is

tapered. Compare the results obtained with

those given in the Specifications.

41 Check the oil seal contact surfaces at

each end of the crankshaft for wear and

damage. If the seal has worn a deep groove in

the surface of the crankshaft, consult an

engine overhaul specialist; repair may be

possible, but otherwise a new crankshaft will

be required.

42 At the time of writing, it was not clear

whether Peugeot produce oversize bearing

shells for all of these engines. On some

engines, if the crankshaft journals have not

already been reground, it may be possible to

have the crankshaft reconditioned, and to fit

oversize shells (see Section 13). If no oversize

shells are available and the crankshaft has

worn beyond the specified limits, it will have

to be renewed. Consult your Peugeot dealer

or engine specialist for further information on

parts availability.

9 Cylinder block/crankcase -

cleaning and inspection

3

Cleaning

1 Remove all external components and

electrical switches/sensors from the block.

2 On aluminium block engines with wet

liners, remove the liners as described in para-

graph 11.

3 Scrape all traces of gasket from the cylinder

block/crankcase, and from the main bearing

ladder (where fitted), taking care not to

damage the gasket/sealing surfaces.

4 Remove all oil gallery plugs (where fitted).

The plugs are usually very tight - they may

have to be drilled out, and the holes re-

tapped. Use new plugs when the engine is

reassembled.

5 If any of the castings are extremely dirty, all

should be steam-cleaned.

6 After the castings are returned, clean all oil

holes and oil galleries one more time. Flush all

internal passages with warm water until the

water runs clear. Dry thoroughly, and apply a

light film of oil to all mating surfaces, to

prevent rusting. On cast-iron block engines,

also oil the cylinder bores. If you have access

to compressed air, use it to speed up the

drying process, and to blow out all the oil

holes and galleries.

Warning: Wear eye protection

when using compressed air!

7 If the castings are not very dirty, you can do

an adequate cleaning job with hot (as hot as

you can stand!), soapy water and a stiff brush.

Take plenty of time, and do a thorough job.

Regardless of the cleaning method used, be

sure to clean all oil holes and galleries very

thoroughly, and to dry all components well.

On cast-iron block engines, protect the

cylinder bores as described above, to prevent

rusting.

8 All threaded holes must be clean, to ensure

accurate torque readings during reassembly.

To clean the threads, run the correct-size tap

into each of the holes to remove rust,

corrosion, thread sealant or sludge, and to

restore damaged threads (see illustration). If

possible, use compressed air to clear the

holes of debris produced by this operation.

Warning: Wear eye protection

when cleaning out these holes

in this way!

9 Apply suitable sealant to the new oil gallery

plugs, and insert them into the holes in the

block. Tighten them securely.

10 If the engine is not going to be

reassembled right away, cover it with a large

plastic bag to keep it clean; protect all mating

surfaces and the cylinder bores as described

above, to prevent rusting.

Inspection (aluminium cylinder

block with wet liners)

11 Remove the liner clamps (where used),

then use a hard wood drift to tap out each

liner from the inside of the cylinder block.

Engine removal and overhaul procedures 2D•13

2D

8.40 Measuring a crankshaft big-end

journal diameter

9.8 Cleaning a cylinder block threaded

hole using a suitable tap