Bleeding - basic (two-man)

method

13 Collect a clean glass jar of reasonable size

and a suitable length of plastic or rubber

tubing, which is a tight fit over the bleed

screw, and a ring spanner to fit the screws.

The help of an assistant will also be required.

14 If not already done, remove the dust cap

from the bleed screw of the first wheel to be

bled and fit the spanner and bleed tube to the

screw (see illustration). Place the other end

of the tube in the jar, and pour in sufficient

fluid to cover the end of the tube.

15 Ensure that the master cylinder reservoir

fluid level is maintained at least above the

“MIN” level line throughout the procedure.

16 Have the assistant fully depress the brake

pedal several times to build up pressure, then

maintain it on the final downstroke.

17 While pedal pressure is maintained,

unscrew the bleed screw (approximately one

turn) and allow the compressed fluid and air to

flow into the jar. The assistant should maintain

pedal pressure, following it down to the floor if

necessary, and should not release it until

instructed to do so. When the flow stops,

tighten the bleed screw again have the

assistant release the pedal slowly, and

recheck the reservoir fluid level.

18 Repeat the steps given in paragraphs 16

and 17 until the fluid emerging from the bleed

screw is free from air bubbles. If the master

cylinder has been drained and refilled, and air

is being bled from the first screw in the

sequence, allow approximately five seconds

between cycles for the master cylinder

passages to refill.

19 On 1.6 GTI models only it is now

important to dislodge air trapped in the inertia

compensator. To do this, open the bleed

screw again and have your assistant fully

depress and release the brake pedal rapidly 4

or 5 times, finally keeping the pedal

depressed before tightening the bleed screw.

20 When no more air bubbles appear, tighten

the bleed screw securely, remove the tube

and spanner and refit the dust cap. Do not

overtighten the bleed screw.

21 Repeat these procedures on the

remaining brakes in sequence until all air is

removed from the system and the brake pedal

feels firm again.

Bleeding - using a one-way

valve kit

22 As their name implies, these kits consist of

a length of tubing with a one-way valve fitted,

to prevent expelled air and fluid being drawn

back into the system; some kits include a

translucent container, which can be positioned

so that the air bubbles can be more easily

seen flowing from the end of the tube.

23 The kit is connected to the bleed screw,

which is then opened. The user returns to the

driver’s seat, depresses the brake pedal with

a smooth steady stroke, and slowly releases

it; this is repeated until the expelled fluid is

clear of air bubbles. When using one of these

kits on 1.6 GTI models, remember to carry out

the procedure described in paragraph 19 after

bleeding the first brake in the sequence.

24 Note that these kits simplify work so

much that it is easy to forget the master

cylinder fluid level; ensure that this is

maintained at least above the “MIN” level line

at all times.

Bleeding - using a pressure-

bleeding kit

25 These kits are usually operated by the

reserve of pressurised air contained in the

spare tyre. However, note that it will probably

be necessary to reduce the pressure to a

lower level than normal; refer to the

instructions supplied with the kit.

26 By connecting a pressurised, fluid-filled

container to the master cylinder reservoir,

bleeding is then carried out by simply opening

each bleed screw in turn (in the specified

sequence) and allowing the fluid to run out,

until no more air bubbles can be seen in the

expelled fluid. When using one of these kits

on 1.6 GTI models, remember to carry out the

procedure described in paragraph 19 after

bleeding the first brake in the sequence.

27 This method has the advantage that the

large reservoir of fluid provides an additional

safeguard against air being drawn into the

system during bleeding.

28 Pressure bleeding is particularly effective

when bleeding “difficult” systems, or when

bleeding the complete system at the time of

routine fluid renewal.

All methods

29 When bleeding is complete, and firm

pedal feel is restored, wash off any spilt fluid,

tighten the bleed screws securely, and refit

their dust caps.

30 Check the hydraulic fluid level in the master

cylinder reservoir and top-up if necessary.

31 Discard any hydraulic fluid that has been

bled from the system; it will not be fit for re-use.

32 Check the feel of the brake pedal. If it feels

at all spongy, air must still be present in the

system, and further bleeding is required.

Failure to bleed satisfactorily after a reasonable

repetition of the bleeding operations may be

due to worn master cylinder seals.

33 On models with ABS, reconnect the wiring

connectors to the regulator unit and

reconnect the battery.

Braking system 9•3

9

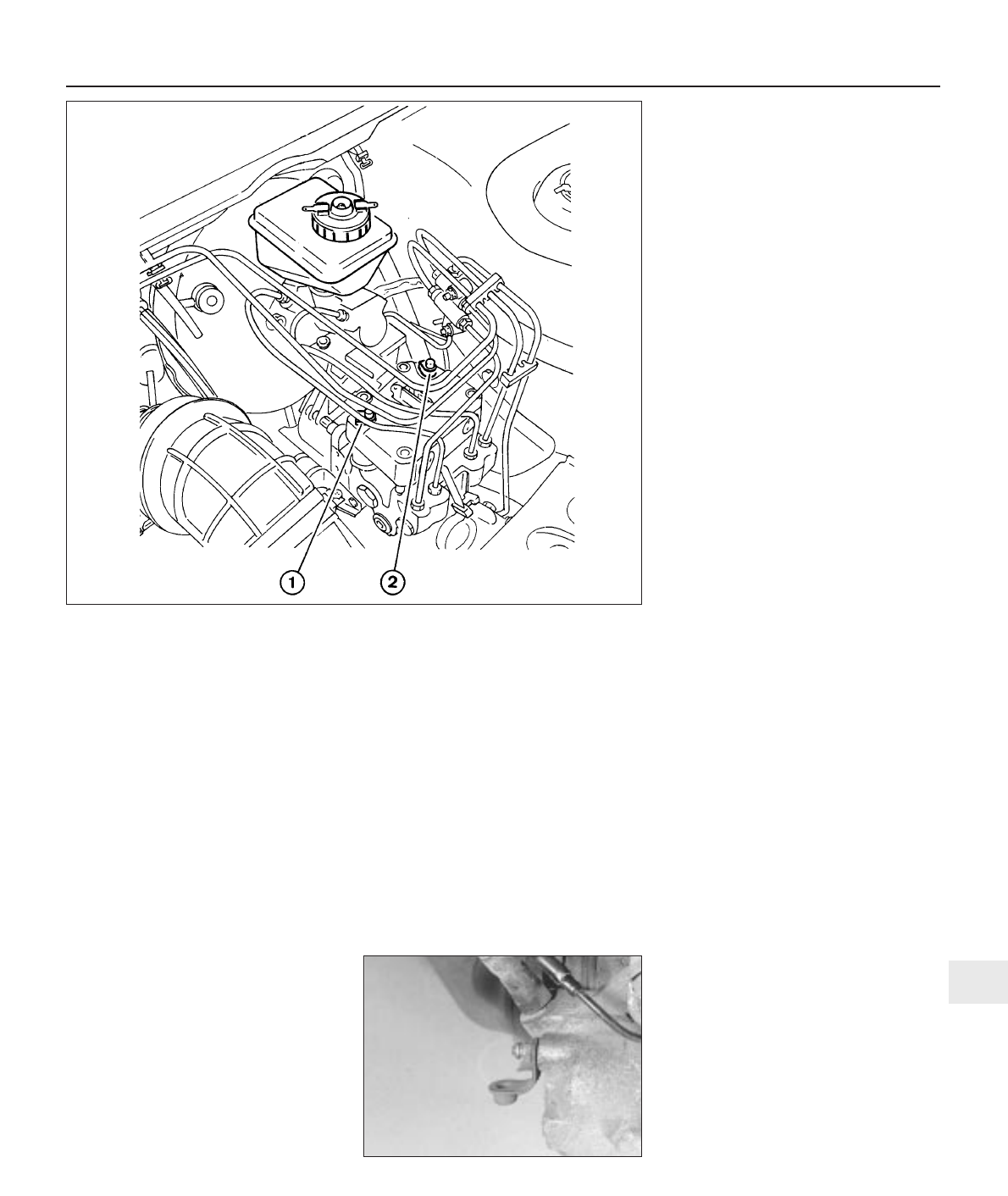

2.12 Bleed screws (1 and 2) on ABS regulator unit

2.14 Bleed screw and dust cap on front

brake caliper