3 Hydraulic pipes and hoses -

renewal

2

Note: Before starting work, refer to the

warning at the beginning of Section 2

concerning the dangers of hydraulic fluid.

1 If any pipe or hose is to be renewed,

minimise hydraulic fluid loss by removing the

master cylinder reservoir cap, placing a piece

of plastic film over the reservoir and sealing it

with an elastic band. Alternatively, flexible

hoses can be sealed, if required, using a

proprietary brake hose clamp; metal brake

pipe unions can be plugged (if care is taken

not to allow dirt into the system) or capped

immediately they are disconnected. Place a

wad of rag under any union that is to be

disconnected, to catch any spilt fluid.

2 If a flexible hose is to be disconnected,

unscrew the brake pipe union nut before

removing the spring clip which secures the

hose to its mounting. Depending upon the

make of the particular caliper, the other end of

the hose may be connected simply by

screwing it into its tapped hole or by using a

hollow bolt with banjo end fitting. Use a new

copper sealing washer on each side of the

banjo union.

3 To unscrew the union nuts, it is preferable to

obtain a brake pipe spanner of the correct size;

these are available from most large motor

accessory shops. Failing this, a close-fitting

open-ended spanner will be required, though if

the nuts are tight or corroded, their flats may be

rounded-off if the spanner slips. In such a case,

a self-locking wrench is often the only way to

unscrew a stubborn union, but it follows that

the pipe and the damaged nuts must be

renewed on reassembly. Always clean a union

and surrounding area before disconnecting it. If

disconnecting a component with more than

one union, make a careful note of the

connections before disturbing any of them.

4 If a brake pipe is to be renewed, it can be

obtained, cut to length and with the union

nuts and end flares in place, from Peugeot

dealers. All that is then necessary is to bend it

to shape, following the line of the original,

before fitting it to the car. Alternatively, most

motor accessory shops can make up brake

pipes from kits, but this requires very careful

measurement of the original, to ensure that

the replacement is of the correct length. The

safest answer is usually to take the original to

the shop as a pattern.

5 Before refitting, blow through the new pipe

or hose with dry compressed air. Do not

overtighten the union nuts. It is not necessary

to exercise brute force to obtain a sound joint.

6 If flexible rubber hoses are renewed, ensure

that the pipes and hoses are correctly routed,

with no kinks or twists, and that they are

secured in the clips or brackets provided.

7 After fitting, bleed the hydraulic system as

described in Section 2, wash off any spilt

fluid, and check carefully for fluid leaks.

4 Front brake pads - renewal

2

Warning: Disc brake pads must

be renewed on both front

wheels at the same time - never

renew the pads on only one

wheel as uneven braking may result. Dust

created by wear of the pads may contain

asbestos, which is a health hazard. Never

blow it out with compressed air and do not

inhale any of it. DO NOT use petroleum-

based solvents to clean brake parts. Use

brake cleaner or methylated spirit only. DO

NOT allow any brake fluid, oil or grease to

contact the brake pads or disc. Also refer

to the warning at the start of Section 2

concerning the dangers of hydraulic fluid.

All models except 1.9 GTI

1 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and vehicle support”). Remove

the front roadwheels.

2 Note that two different types of brake

caliper may be fitted according to model and

year. Identify the type fitted, with reference to

the accompanying illustrations or the caliper

itself, then proceed as described under the

relevant sub-heading.

DBA Bendix caliper

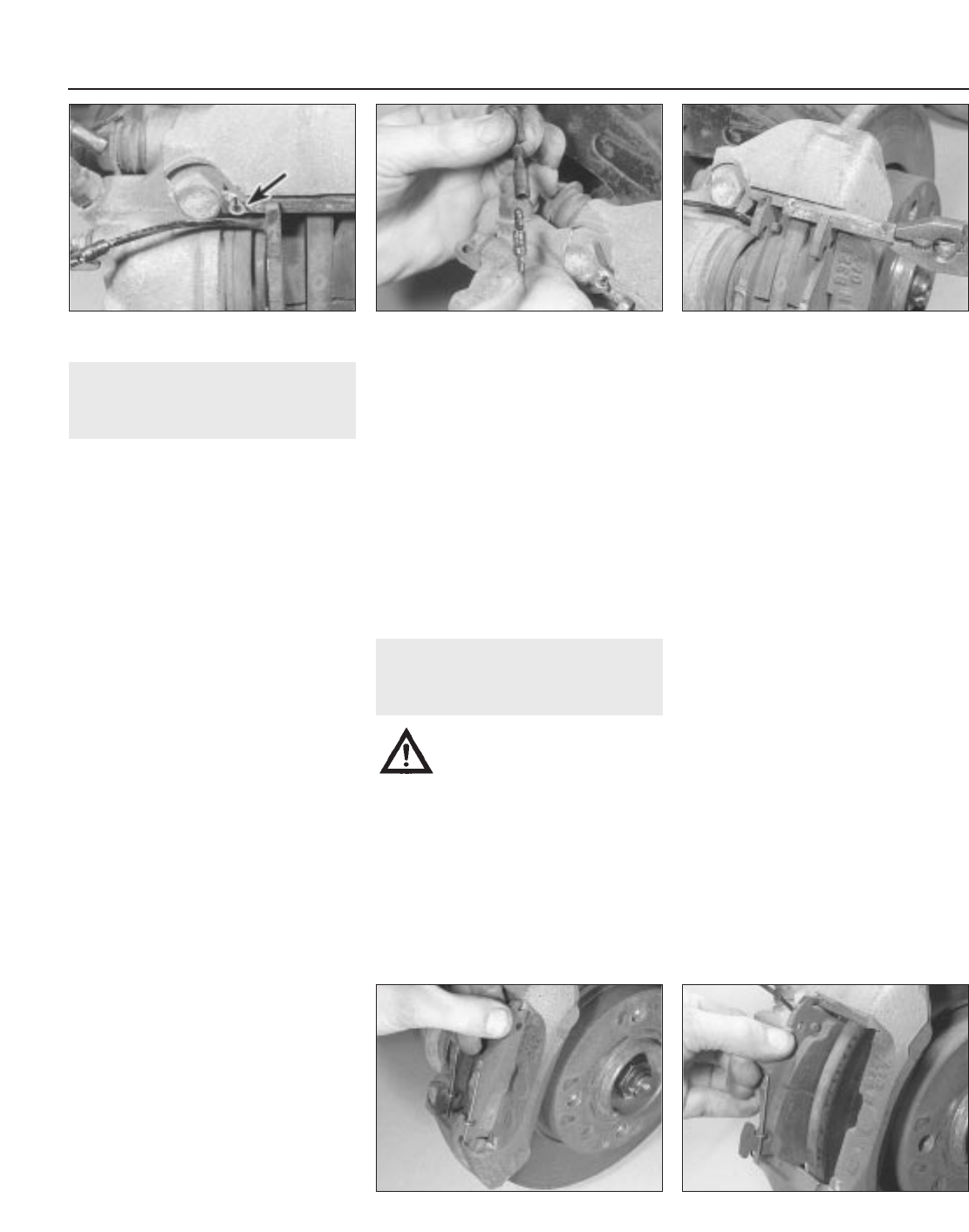

3 Remove the clip from the end of the upper

sliding key. Disconnect the pad wear wiring

connector as necessary (see illustrations).

4 Pull out the upper sliding key (see

illustration).

5 Using a lever against the front suspension

strut, push the cylinder towards the brake disc

so that the outer pad can be withdrawn from

the caliper (see illustration).

6 Push back the caliper and withdraw the

inner pad (see illustration). Make a note of

the correct fitted position of the anti-rattle

springs and remove the spring from each pad.

7 Clean away all dust and dirt from the

caliper. Check for brake fluid leakage around

the piston dust seal and, if evident, overhaul

the caliper, as described later in this Chapter.

Check the brake disc for wear and also check

that the rubber bellows on the cylinder sliding

rods are in good condition.

8 Clean the backs of the brake pads and

apply a little anti-squeal brake grease. Also

apply the grease to the lower pad locating lip

of the caliper.

9•4 Braking system

4.3a Pad sliding key clip - arrowed

(DBA Bendix caliper)

4.3b Disconnecting the pad wear wiring

connector (DBA Bendix caliper)

4.4 Removing the pad sliding key

(DBA Bendix caliper)

4.5 Removing the outer pad

(DBA Bendix caliper)

4.6 Removing the inner pad

(DBA Bendix caliper)