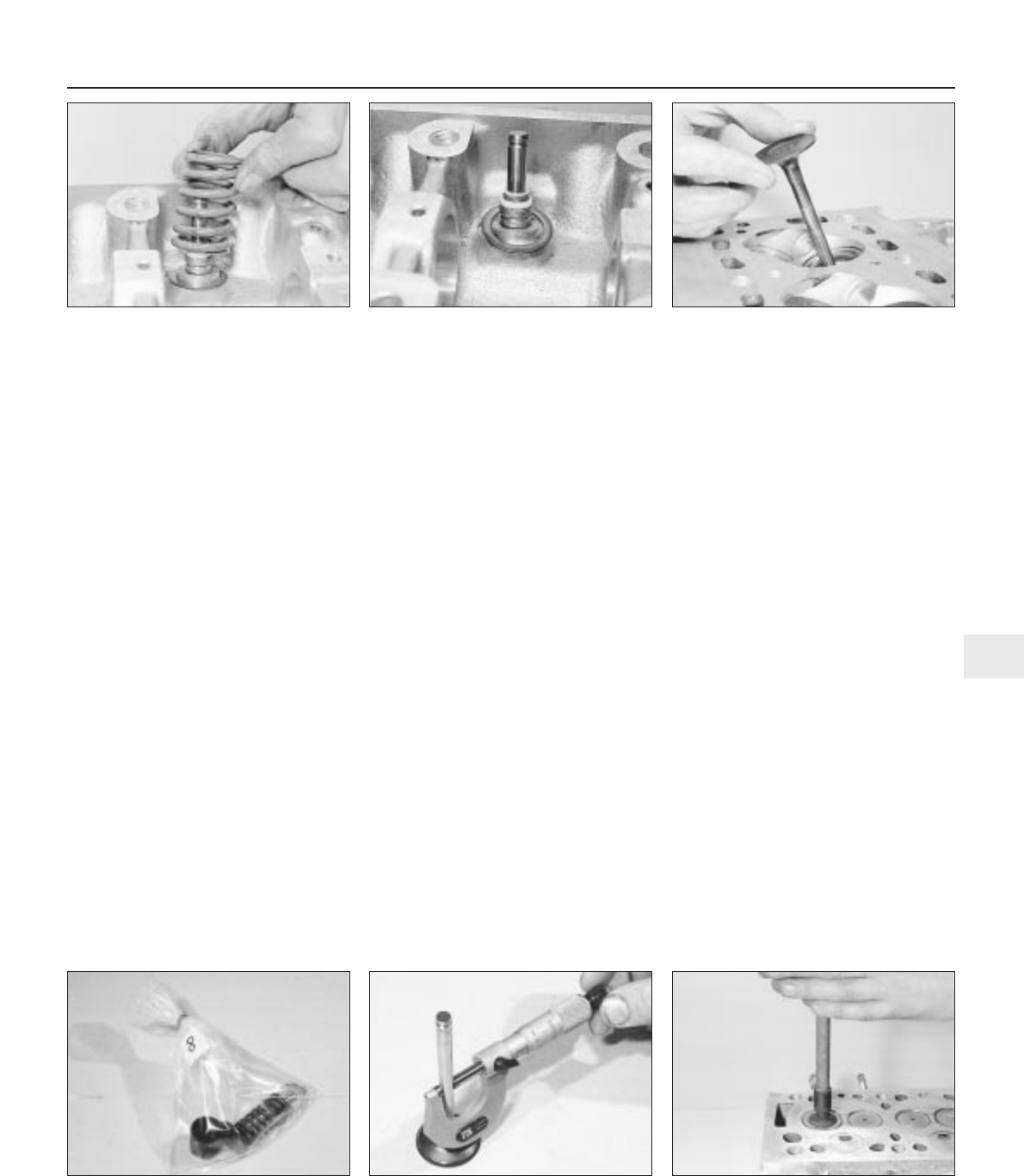

7 It is essential that each valve is stored

together with its collets, retainer, spring, and

spring seat. The valves should also be kept in

their correct sequence, unless they are so badly

worn that they are to be renewed. If they are

going to be kept and used again, place each

valve assembly in a labelled polythene bag or

similar small container (see illustration). Note

that No 1 valve is nearest to the transmission

(flywheel/driveplate) end of the engine.

Cleaning

8 Thoroughly clean all traces of old gasket

material and sealing compound from the

cylinder head upper and lower mating

surfaces. Use a suitable cleaning agent

together with a soft putty knife; do not use a

metal scraper or the faces will be damaged.

9 Remove the carbon from the combustion

chambers and ports, then clean all traces of

oil and other deposits from the cylinder head,

paying particular attention to the bearing

journals, cam follower bores (where

applicable), valve guides and oilways.

10 Wash the head thoroughly with paraffin or

a suitable solvent. Take plenty of time and do

a thorough job. Be sure to clean all oil holes

and galleries very thoroughly, dry the head

completely and coat all machined surfaces

with light oil.

11 Scrape off any heavy carbon deposits that

may have formed on the valves, then use a

power-operated wire brush to remove

deposits from the valve heads and stems.

Inspection

Note: Be sure to perform all the following

inspection procedures before concluding that

the services of an engineering works are

required. Make a list of all items that require

attention.

Cylinder head

12 Inspect the head very carefully for cracks,

evidence of coolant leakage, and other

damage. If cracks are found, a new cylinder

head should be obtained.

13 Use a straight-edge and feeler blade to

check that the cylinder head gasket surface is

not distorted. If it is, it may be possible to

have it machined. Seek the advice of a

Peugeot dealer or engine overhaul specialist if

distortion is suspected.

14 Examine the valve seats in each of the

combustion chambers. If they are severely

pitted, cracked, or burned, they will need to

be renewed or re-cut by an engine overhaul

specialist. If they are only slightly pitted, this

can be removed by grinding-in the valve

heads and seats with fine valve-grinding

compound, as described below.

15 Check the valve guides for wear by

inserting the relevant valve, and checking for

side-to-side motion of the valve. A very small

amount of movement is acceptable. If the

movement seems excessive, remove the valve.

Measure the valve stem diameter (see below),

and renew the valve if it is worn. If the valve

stem is not worn, the wear must be in the valve

guide, and the guide must be renewed. The

renewal of valve guides is best carried out by a

Peugeot dealer or engine overhaul specialist,

who will have the necessary tools available.

16 If renewing the valve guides, the valve

seats should be re-cut or re-ground only after

the guides have been fitted.

Valves

17 Examine the head of each valve for pitting,

burning, cracks, and general wear. Check the

valve stem for scoring and wear ridges. Rotate

the valve, and check for any obvious indication

that it is bent. Look for pits or excessive wear

on the tip of each valve stem. Renew any valve

that shows any such signs of wear or damage.

18 If the valve appears satisfactory at this

stage, measure the valve stem diameter at

several points using a micrometer (see

illustration). Any significant difference in the

readings obtained indicates wear of the valve

stem. Should any of these conditions be

apparent, the valve(s) must be renewed.

19 If the valves are in satisfactory condition,

they should be ground (lapped) into their

respective seats, to ensure a smooth, gas-

tight seal. If the seat is only lightly pitted, or if

it has been re-cut, fine grinding compound

only should be used to produce the required

finish. Coarse valve-grinding compound

should not be used, unless a seat is badly

burned or deeply pitted. If this is the case, the

cylinder head and valves should be inspected

by an expert, to decide whether seat re-

cutting, or even the renewal of the valve or

seat insert (where possible) is required.

20 Valve grinding is carried out as follows.

Place the cylinder head upside-down on a

bench.

21 Smear a trace of (the appropriate grade

of) valve-grinding compound on the seat face,

and press a suction grinding tool onto the

valve head (see illustration). With a semi-

rotary action, grind the valve head to its seat,

Engine removal and overhaul procedures 2D•9

2D

6.4c . . . spring . . . 6.4d . . . spring seat and valve stem oil

seal

6.6 Withdraw the valve through the

combustion chamber

6.7 Place each valve and its associated

components in a labelled polythene bag

6.18 Measuring the valve stem diameter 6.21 Grinding-in a valve