9 Carburettor - removal and

refitting

2

Note: Observe the precautions in Section 1

before working on any component in the fuel

system.

Removal

1 Remove the air cleaner assembly, as

described in Section 2.

2 Unscrew the bolts or nuts and remove the

air inlet duct from the top of the carburettor(s).

3 Disconnect the throttle cable or ball-jointed

throttle control rod from the carburettor(s)

with reference to Section 3 (see illustration).

4 Disconnect the choke cable with reference

to Section 4.

5 Where fitted, remove the short hose which

runs between the oil filler cap and the

carburettor.

6 Disconnect the wiring connector from the

idle cut-off solenoid as applicable.

7 Slacken the retaining clip, and disconnect

the fuel feed hose from the carburettor. Place

wads of rag around the union to catch any

spilled fuel, and plug the hose as soon as it is

disconnected, to minimise fuel loss.

8 Make a note of the correct fitted positions

of all the relevant vacuum pipes and breather

hoses, to ensure that they are correctly

positioned on refitting, then release the

retaining clips (where fitted) and disconnect

them from the carburettor.

9 Disconnect and plug the carburettor

coolant hose(s). Plug the hoses immediately

to prevent coolant loss.

10 Unscrew the nuts and washers securing

the carburettor(s) to the inlet manifold.

Remove the carburettor assembly from the

car. Remove the insulating spacer and/or

gasket(s). Discard the gasket(s); new ones

must be used on refitting. Plug the inlet

manifold port with a wad of clean cloth, to

prevent the possible entry of foreign matter.

Refitting

11 Refitting is the reverse of the removal

procedure, noting the following points:

a) Ensure that the carburettor and inlet

manifold sealing faces are clean and flat.

Fit a new gasket, and securely tighten the

carburettor retaining nuts.

b) Use the notes made on dismantling to

ensure that all hoses are refitted to their

original positions and, where necessary,

are securely held by their retaining clips.

c) Where the original crimped-type Peugeot

hose clips were fitted, discard them; use

standard worm-drive hose clips when

refitting.

d) Refit and adjust the throttle cable and

choke cable (where applicable) as

described in Sections 3 and 4.

e) Refit the air cleaner assembly as

described in Section 2.

f) Top-up the cooling system as described

in “Weekly checks”.

g) On completion, check and, if necessary,

adjust the idle speed and mixture settings

as described in Chapter 1.

10 Carburettor - fault diagnosis,

overhaul and adjustments

3

Fault diagnosis

1 If a carburettor fault is suspected, always

check first that the ignition timing is correctly

set, that the spark plugs are in good condition

and correctly gapped, that the throttle and

choke cables are correctly adjusted, and that

the air cleaner filter element is clean; refer to

the relevant Sections of Chapter 1, Chapter 5

or this Chapter. If the engine is running very

roughly, first check the valve clearances as

described in Chapter 1, then check the

compression pressures as described in

Chapter 2.

2 If careful checking of all the above

produces no improvement, the carburettor

must be removed for cleaning and overhaul.

3 Prior to overhaul, check the availability of

component parts before starting work; note

that most sealing washers, screws and

gaskets are available in kits, as are some of

the major sub-assemblies. In most cases, it

will be sufficient to dismantle the carburettor

and to clean the jets and passages.

Overhaul

Note: Refer to the warning note in Section 1

before proceeding. The following procedures

are typical for the various carburettors

encountered on 205 models. Refer to the

accompanying illustrations for details of

specific carburettor types and component

locations.

4 Remove the carburettor from the car as

described in Section 9.

5 Unscrew the idle cut-off solenoid (where

fitted) from the carburettor body, and remove

it along with its plunger and spring. To test the

solenoid, connect a 12-volt battery to it

(positive terminal to the solenoid terminal,

negative terminal to the solenoid body), and

check that the plunger is retracted fully into

the body. Disconnect the battery, and check

that the plunger is pushed out by spring

pressure. If the valve does not perform as

expected, and cleaning does not improve the

situation, the solenoid valve must be renewed.

6 Remove the screws and lift off the

carburettor upper body.

7 Tap out the float pivot pin and remove the

float assembly, needle valve, and float

chamber gasket. Check that the needle valve

anti-vibration ball is free in the valve end, then

examine the needle valve tip and seat for wear

or damage. Examine the float assembly and

pivot pin for signs of wear and damage. The

float assembly must be renewed if it appears

to be leaking - shake the float to detect the

presence of fuel inside.

8 Unscrew the fuel inlet union and inspect the

fuel filter. Clean the filter housing of debris

and dirt, and renew the filter if it is blocked.

9 Undo the screws and remove the various

diaphragm covers and diaphragms. Remove

the diaphragm(s) and spring(s), noting which

way around all the parts are fitted. Examine

the diaphragm(s) for signs of damage and

deterioration, and renew if necessary.

10 Unscrew the jets from the upper body and

main body making notes as to their location

and arrangement.

11 Remove the idle mixture adjustment

screw tamperproof cap if fitted. Screw the

screw in until it seats lightly, counting the

exact number of turns required to do this,

then unscrew it. On refitting, screw the screw

in until it seats lightly, then back the screw off

by the number of turns noted on removal, to

return the screw to its original position.

12 Clean the jets, carburettor body

assemblies, float chamber and internal

drillings. An air line may be used to clear the

internal passages once the carburettor is fully

dismantled.

Caution: If high pressure air is directed into

drillings and passages where a diaphragm

is fitted, the diaphragm is likely to be

damaged.

13 Use a straight edge to check all

carburettor body assembly mating surfaces

for distortion.

14 On reassembly renew any worn

components and fit a complete set of new

gaskets and seals. A jet kit and a gasket and

seal kit are available from your Peugeot dealer.

15 Reassembly is a reversal of the

dismantling procedure. Ensure that all jets are

securely locked in position, but take great care

not to overtighten them. Ensure that all mating

surfaces are clean and dry, and that all body

sections are correctly assembled with their

fuel and air passages correctly aligned. Prior

to refitting the carburettor to the car, carry out

all the applicable adjustments, according to

carburettor type as described below.

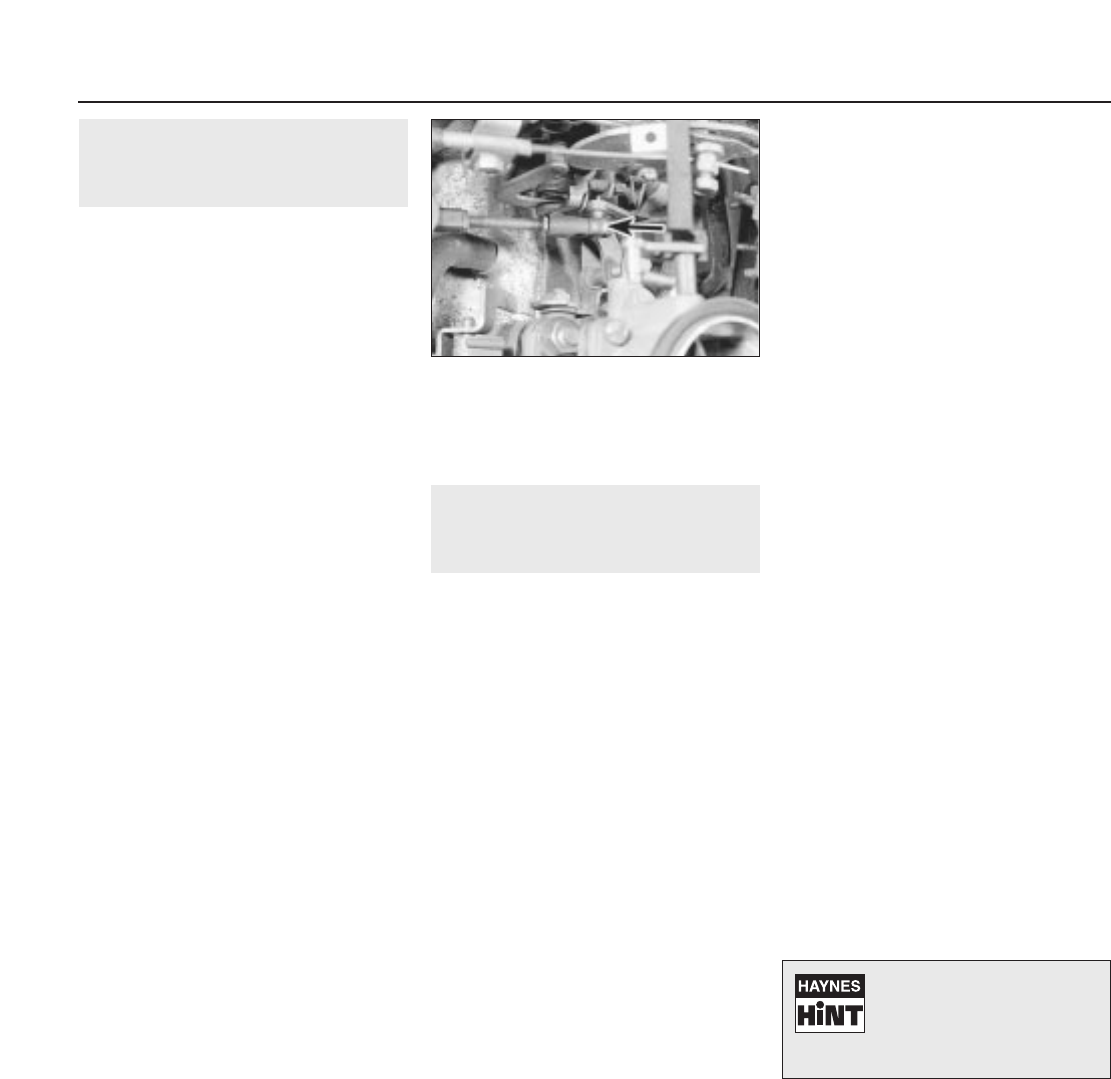

4A•6 Fuel system - carburettor engines

9.3 Ball-jointed throttle control rod

(arrowed)

Aerosol cans of carburettor

cleaner are widely available

and can prove very useful in

helping to clear internal

passages of stubborn obstructions.