5B.19

Section 5B

EFI Fuel System

5B

pump preventing the continued delivery of fuel. In

this situation, the MIL will go on, but it will go back

off after 4 cranking revolutions if system function is

OK. Once the engine is running, the fuel pump

remains on.

Service

The fuel pumps are non-serviceable and must be

replaced if determined to be faulty. If a fuel delivery

problem is suspected, make certain the pump is being

activated through the relay, all electrical connections

are properly secured, the fuses are good, and a

minimum of 7.0 volts is being supplied. If during

cranking, voltage drops below 7.0 volts, a reduction of

fuel pressure may occur resulting in a lean starting

condition. If required, testing of the fuel pump and

relay may be conducted.

1. Connect the black hose of Pressure Tester (part of

EFI Service Kit, see Section 2) to the test valve in

the fuel rail. Route the clear hose into a portable

gasoline container or the equipment fuel tank.

2. Turn on the key switch to activate the pump and

check the system pressure on the gauge. If system

pressure of 39 psi ± 3 is observed, the relay, fuel

pump, and regulator are working properly. Turn

key switch off and depress the valve button on

the tester to relieve the system pressure.

a. If the pressure is too high, and the regulator

is outside the tank (just down line from the

pump), check that the return line from the

regulator to the tank is not kinked or

blocked. If the return line is good, replace

the regulator (see ‘‘Regulator Service’’ on

page 5B.20).

b. If the pressure is too low, install in-line ‘‘T’’

between the pump and the regulator and

retest the pressure at that point. If it is too low

there also, replace the fuel pump.

3. If the pump did not activate (step 2), disconnect

the plug from the fuel pump. Connect a DC

voltmeter across the terminals in the plug, turn

on the key switch and observe if a minimum of 7

volts is present. If voltage is between 7 and 14,

turn key switch off and connect an ohmmeter

between the terminals on the pump to check for

continuity.

a. If there was no continuity between the pump

terminals, replace the fuel pump.

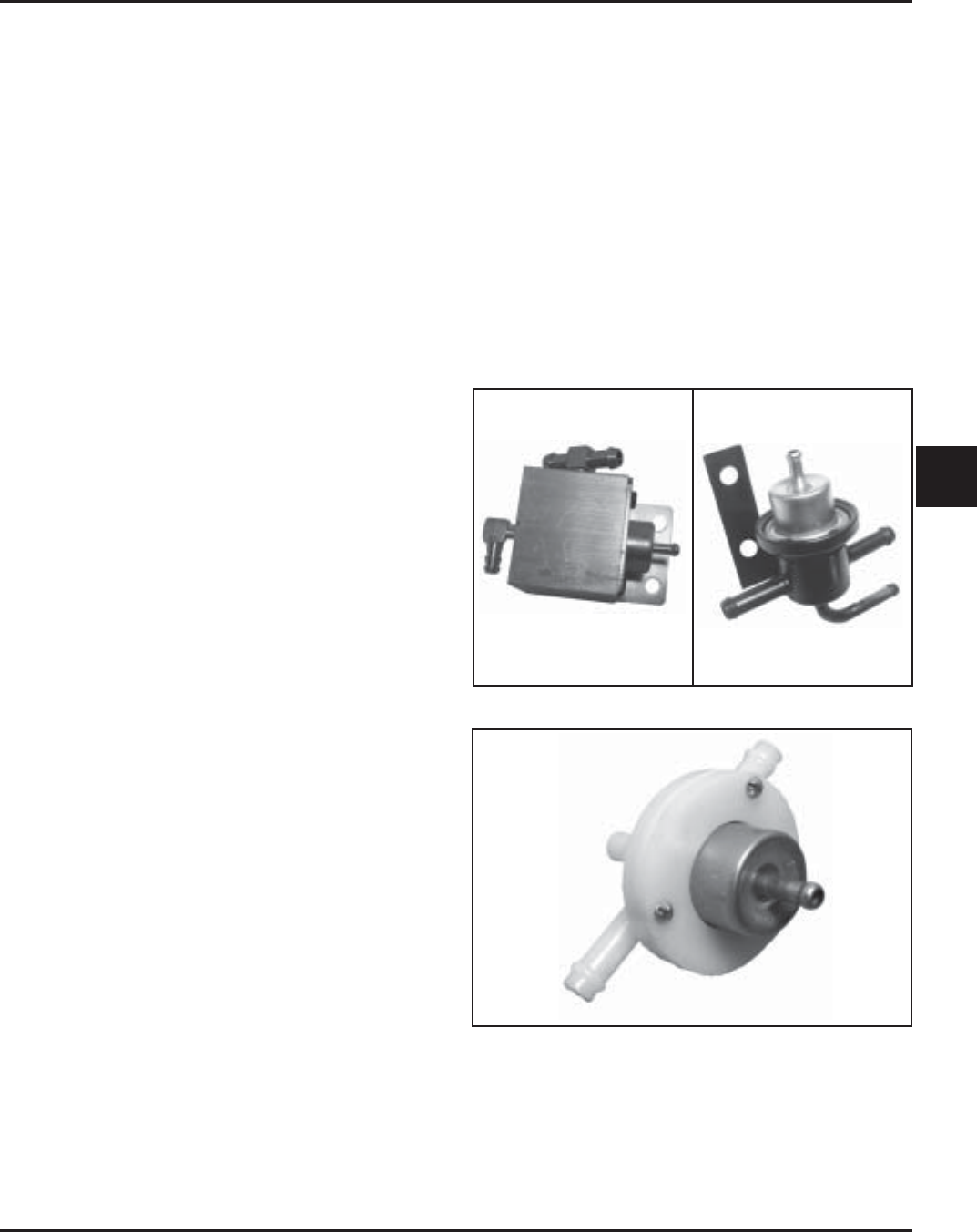

Figure 5B-24. External Fuel Pressure Regulators.

Figure 5B-25. Internal Fuel Pressure Regulators.

b. If the voltage was below 7, test the wiring

harness and relay as covered in the

‘‘Electrical Relay’’ section.

4. If voltage at the plug was good, and there was

continuity across the pump terminals, reconnect

the plug to the pump, making sure you have a

good connection. Turn on the key switch and

listen for the pump to activate.

a. If the pump starts, repeat steps 1 and 2 to

verify correct pressure.

b. If the pump still does not operate, replace it.

Fuel Pressure Regulator