5B.10

Section 5B

EFI Fuel System

Oxygen Sensor

General

The engine (oil) temperature sensor (Figure 5B-8) is

used by the system to help determine fuel

requirements for starting (a cold engine needs more

fuel than one at or near operating temperature).

Mounted in the oil filter adapter housing, it has a

temperature-sensitive resistor that extends into the oil

flow. The resistance changes with oil temperature,

altering the voltage sent to the ECU. Using a table

stored in its memory, the ECU correlates the voltage

drop to a specific temperature. Using the fuel delivery

“maps”, the ECU then knows how much fuel is

required for starting at that temperature.

Service

The temperature sensor is a sealed, non-serviceable

assembly. A faulty sensor must be replaced. If a blink

code indicates a problem with the temperature sensor,

it can be tested as follows:

1. Remove the temperature sensor from the adapter

housing and cap or block the adapter hole.

2. Wipe the sensor clean and allow it to reach room

temperature (20°C, 68°F).

3. Unplug the main harness connector from the

ECU.

4. With the sensor still connected, check the

temperature sensor circuit resistance between the

#6 and #4 pin terminals (see chart on page 5B.26

(24 pin) or 5B.29 (32 pin) for pin positions). The

value should be 2375-2625

ΩΩ

ΩΩ

Ω.

5. Unplug the sensor from the wire harness and

check the sensor resistance separately. Resistance

value should again be 2375-2625

ΩΩ

ΩΩ

Ω.

a. If the resistance is out of specifications,

replace the temperature sensor.

b. If it is within specifications, proceed to Step 6.

6. Check the circuits (input, ground), from the main

harness connector to the sensor plug for

continuity, damage, etc. Connect one ohmmeter

lead to pin terminal #6 in the main harness

connector (as in step 4). Connect the other lead to

terminal #1 in the sensor plug (see diagram).

Continuity should be indicated. Repeat the test

between pin terminal #4 and terminal #2 in the

sensor plug.

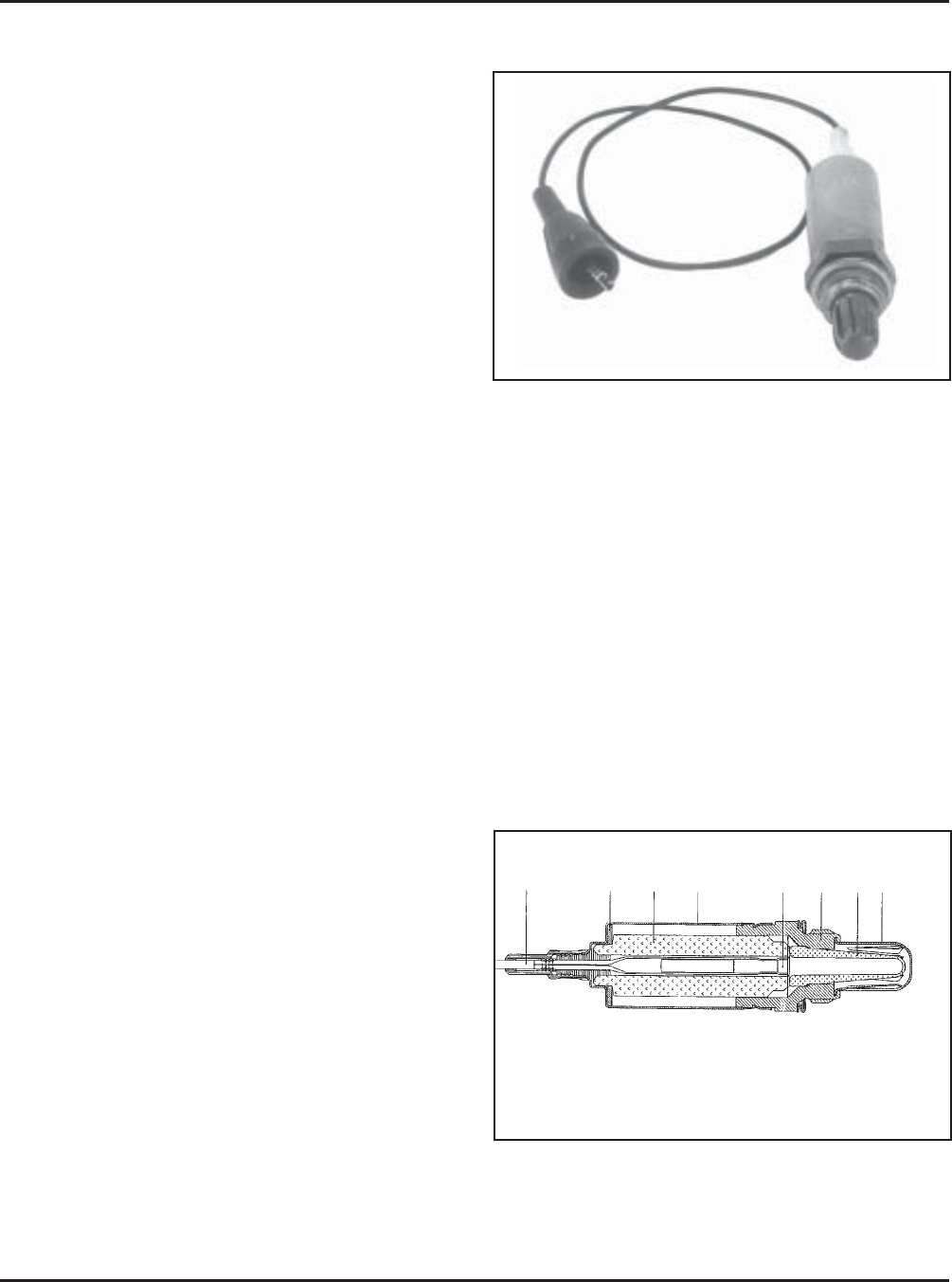

Figure 5B-9. Oxygen Sensor.

General

The oxygen sensor functions like a small battery,

generating a voltage signal to the ECU based upon the

difference in oxygen content between the exhaust gas

and the ambient air.

The tip of the sensor, protruding into the exhaust gas,

is hollow (see cutaway Figure 5B-10). The outer

portion of the tip is surrounded by the exhaust gas,

with the inner portion exposed to the ambient air.

When the oxygen concentration on one side of the tip

is different than that of the other side, a voltage signal

between 0.2 and 1.0 volts is generated between the

electrodes and sent to the ECU. The voltage signal

tells the ECU if the engine is straying from the ideal

14.7:1 fuel mixture, and the ECU then adjusts the

injector pulse accordingly.

1

2

3

4

5

6

7

8

1. Connection Cable

2. Disc Spring

3. Ceramic Support Tube

4. Protective Sleeve

5. Contact Element

6. Sensor Housing

7. Active Ceramic Sensor

8. Protective Tube

Figure 5B-10. Cutaway of Oxygen Sensor.