5B.8

Section 5B

EFI Fuel System

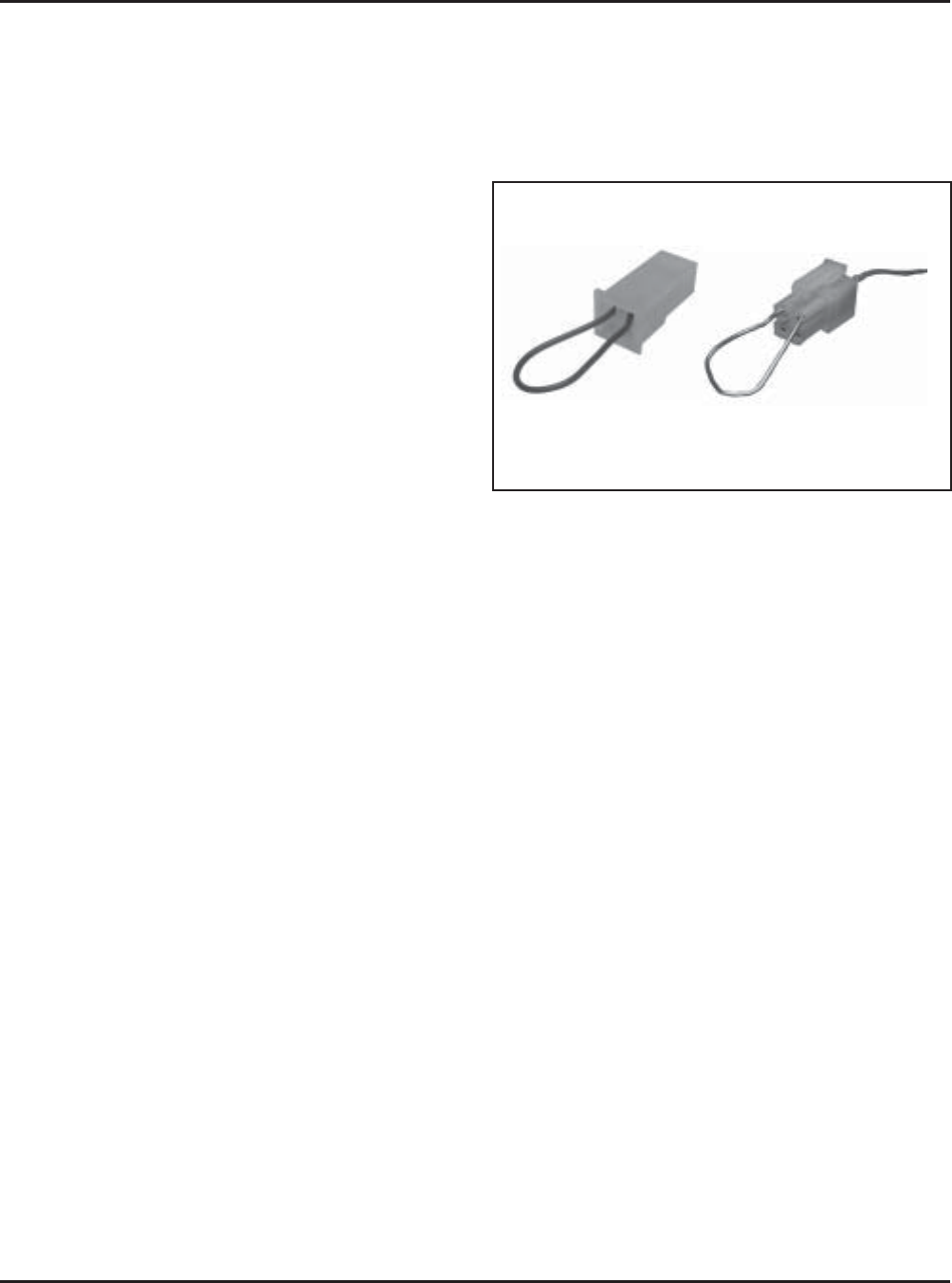

Figure 5B-7. Service Connector Plug, Plastic

Cased ECU Harness.

8. Hold the throttle against the idle speed stop

screw, turn the ignition switch to the “on”

position (do not start the engine), and observe the

Malfunction Indicator Light (MIL).

a. The light should blink on/off quickly for

approximately 3 seconds and then go off and

stay off, indicating the initialization

procedure has been successful.

b. If the light stays on or blinking ceases

prematurely, the procedure was unsuccessful

and must be repeated. Possible causes for

unsuccessful learning may be: 1) Movement

occurred in either the TPS or throttle shaft

during procedure, 2) Crankshaft movement

wasdetected by the speed sensor during

procedure, 3) Throttle plate position was out

of learnable range (recheck the 1500 RPM idle

speed adjustment), or 4) Problem with ECU

or TPS.

9. When the initialization procedure has been

successfully completed, turn off the key switch,

remove the jumper wire or connector, and

remove the rubber band from the throttle lever.

10. Disconnect the ECU connector plug or the

negative (-) battery cable temporarily (one

minute minimum) to clear all learned

adjustments.

“24 Pin” (MSE 1.0) Plastic-Cased ECU: Pin

circuits #8 and #4.

“32 Pin” (MSE 1.1) Plastic-Cased ECU: Pin

circuits #8 and #4.

a. Repair or replace as required.

b. Turn the idle speed screw back in to its

original setting.

c. Reconnect connector plugs, start engine and

retest system operation.

7. Remove the two mounting screws from the TPS.

Save the screws for reuse. Remove and discard

the faulty TPS. Install the replacement TPS and

secure with the original mounting screws.

a. Reconnect both connector plugs.

b. Perform the appropriate “TPS Initialization

Procedure” integrating the new sensor to the

ECU.

TPS Initialization Procedure

For “24 Pin” (MSE 1.0) Plastic-Cased ECU only

1. Check that the basic engine, all sensors, fuel, fuel

pressure, and battery are good and functionally

within specifications.

Important!

2. Remove/disconnect all external loads from the

engine (belts, pumps, electric PTO clutch,

alternator, rectifier-regulator, etc.).

3. Start the engine and allow it to warm up for 5-10

minutes, so oil temperature is above 55°C (130°F).

4. Move the throttle control to the idle position and

allow the engine to stabilize for a minimum of

one minute.

5. Install a heavy rubber band around the throttle

lever and the manifold boss. On some EFI engines

there is a dampening spring on the end of the idle

speed screw. The dampening spring (if used)

should be fully compressed and the tab on the

throttle lever in direct contact with the speed

screw. Adjust the idle speed to 1500 RPM, using a

tachometer.

6. Shut off the engine.

7. Locate the service connector plug in the wiring

harness. Connect a jumper wire from the TPS

initialization pin #24 (violet wire) to the battery

voltage pin (red wire), or use the jumper

connector plug with the blue jumper wire. See

Figure 5B-7.