5.8

Section 5

Fuel System and Governor

High Altitude Operation

When operating the engine at altitudes of 1500 m

(5000 ft.) and above, the fuel mixture tends to get over-

rich. This can cause conditions such as black, sooty

exhaust smoke, misfiring, loss of speed and power,

poor fuel economy, and poor or slow governor

response.

To compensate for the effects of high altitude, special

high altitude jet kits are available. The kits include a

new main jet, slow jet (where applicable), necessary

gaskets and O-Rings. Refer to the parts manual for the

correct kit number.

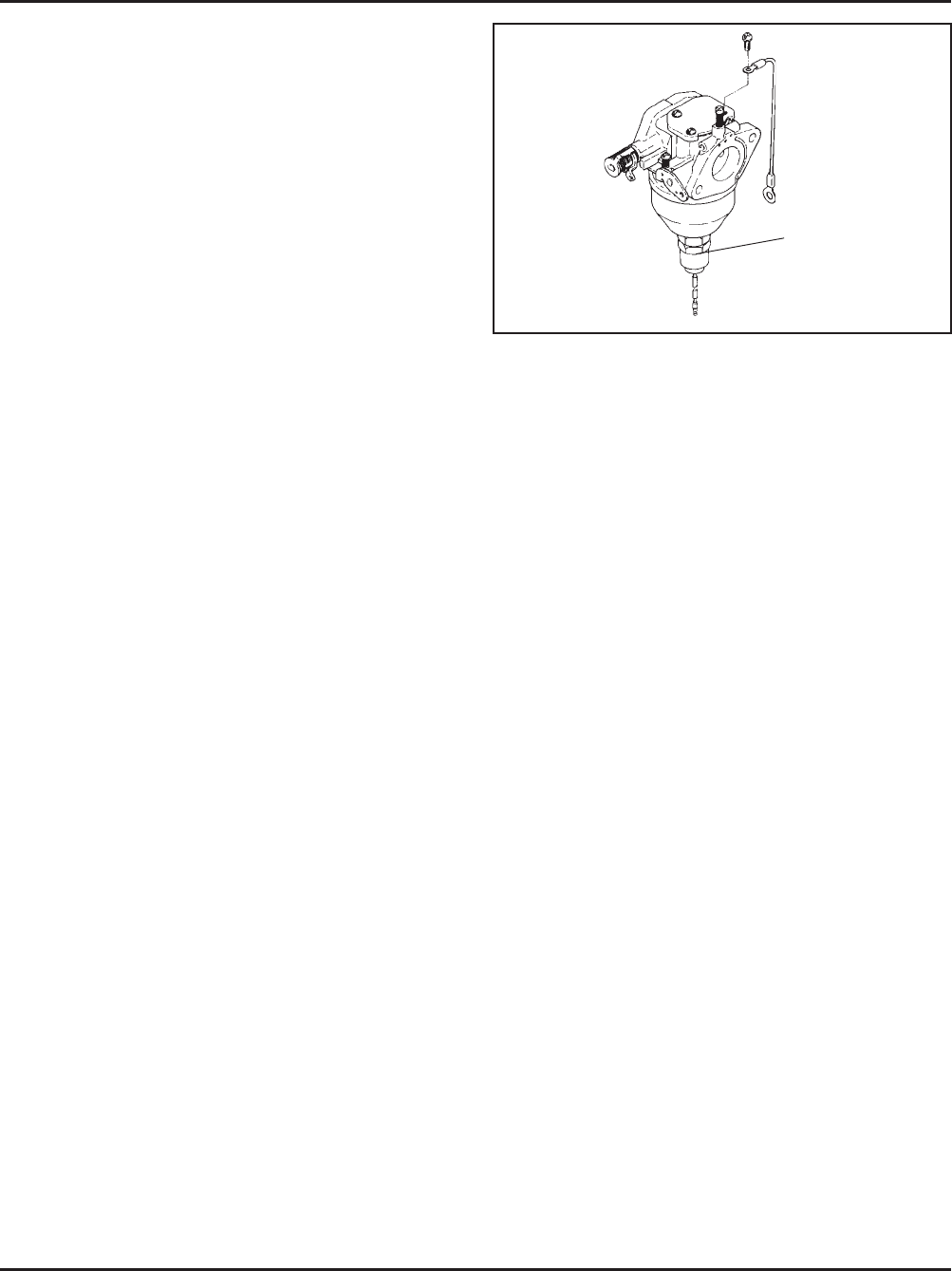

Fuel Shut-off Solenoid

Some carburetors are equipped with an optional fuel

shut-off solenoid. The solenoid is installed in place of

the bowl retaining screw. The solenoid has a spring-

loaded pin that retracts when 12 volt current is

applied to the lead. When it is extended, the main fuel

jet is blocked, preventing normal carburetor operation.

Below is a simple test, made with the engine off, that

can determine if the solenoid is functioning properly:

1. Shut off the fuel and remove the solenoid from

the carburetor. When the solenoid is loosened

and removed, gas will leak out of the carburetor.

Have a container ready to catch the fuel. The

main jet is mounted in the tip of the solenoid pin.

Be careful that it does not get damaged while the

solenoid is separated from the carburetor.

2. Wipe the tip of the solenoid with a shop towel or

blow it off with compressed air, to remove any

remaining fuel. Take the solenoid to a location

with good ventilation and no fuel vapors present.

You will also need a 12 volt power source that can

be switched on and off.

3. Be sure the power source is switched “off”.

Connect the positive power source lead to the red

lead of the solenoid. Connect the negative power

source lead to the solenoid body.

4. Turn the power source “on” and observe the pin

in the center of the solenoid. The pin should

retract with the power “on” and return to its

original position with the power off. Test several

times to verify operation.

Figure 5-5. Fuel Shut-off Solenoid Location.

Carburetor Adjustments (CV17-740)

General

The carburetor is designed to deliver the correct fuel-

to-air mixture to the engine under all operating

conditions. The high speed mixture adjustment is set

at the factory and cannot be adjusted. The low idle

fuel adjusting needle (some models) is also set at the

factory and normally does not need adjustment.

Depending on model and application, engines may

also be equipped with a “Governed Idle System.” If

equipped with a “Governed Idle System”, refer to

“Models with Governed Idle System” when

performing any carburetor adjustment, as an

additional step to the listed adjustment procedure(s) is

required.

NOTE: Carburetor adjustments should be made only

after the engine has warmed up.

NOTE: Certified engines may have a fixed idle or

limiter cap on the idle fuel adjusting needle.

Do not attempt steps 1 and 2 below. Proceed

directly to step 3. Step 5 can only be

performed within the limits allowed by the

cap.

Adjusting Low Idle Fuel and Speed

To adjust the carburetor idle fuel and speed, see

Figure 5-6 and follow these steps.

1. With the engine stopped, turn the low idle fuel

adjusting needle (if equipped) in (clockwise) until

it bottoms lightly.

Fuel Shut-Off

Solenoid