INSTALLING THE AT10.1

14

1.8. MAKING THE DC OUTPUT CONNECTIONS

Follow these steps to connect the battery to the AT10.1:

1. Size the dc wiring to minimize voltage drop. The acceptable wire size

depends on your installation. As a guideline, the voltage drop should not

exceed 1% of nominal output voltage at full current. Refer to the table below

to determine the voltage drops for various wire sizes, currents and distances.

WIRE SIZING CHART

VOLTAGE DROP PER 100ft / 30.5m OF WIRE (FOR COPPER AT 68° F / 20° C)

DC CURRENT (AMPERES) WIRE SIZE

(AWG.)

6 12 16 20 25

16

2.5V 5.0V 6.7V 8.2V 10.5V

14

1.6V 3.2V 4.2V 5.3V 6.6V

12

1.0V 2.0V 2.6V 3.3V 4.2V

10

0.63V 1.3V 1.7V 2.1V 2.6V

8

0.40V 0.80V 1.1V 1.3V 1.7V

6

0.25V 0.50V 0.66V 0.83V 1.1V

4

0.16V 0.32V 0.42V 0.52V 0.65V

EXAMPLE: 100ft / 30.5m of #8 AWG. wire at 16A has a 1.1V drop.

2. All specific requirements of your facility take precedence over these

instructions.

3. The AT10.1 is factory wired to regulate output voltage at the output

terminals. If the total voltage drop is greater than 1% (e.g., 1.3V for a 130

Vdc system), remote sense wiring is recommended, see section 1.9.

PROCEDURE

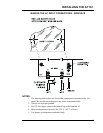

1. Use a dc disconnect switch or circuit breaker between the AT10.1 and dc

bus. This device should have lockout capability to allow the AT10.1 to be

disconnected from the dc bus for maintenance.

2. Remove the safety cover.

3. Run the dc wiring to terminals TB1(+) and TB1(-) on the I/O panel in the

enclosure. Compression lugs, accepting wire sizes #14-6 AWG., are

supplied for your convenience. To make these connections, strip the

insulation .50in / 12.7mm on the incoming wires. Connect the wires to the

appropriate lugs as shown on the next page.

4. Using a flat-head screwdriver, securely tighten the compression screws on

the lugs to 35-45 in-lb / 4.0-5.1 Nm.

5. Reinstall the safety cover after you have made and checked all connections.