5 - 71

ENG

CONNECTING RODS AND PISTONS

e. Tighten the connecting rod nuts.

f. Replace the connecting rod bolts and nuts

with new ones.

CAUTION:

Tighten the connecting rod bolts using the

plastic-region tightening angle method.

Always install new bolts and nuts.

g. Clean the connecting rod bolts and nuts.

h. Tighten the connecting rod nuts.

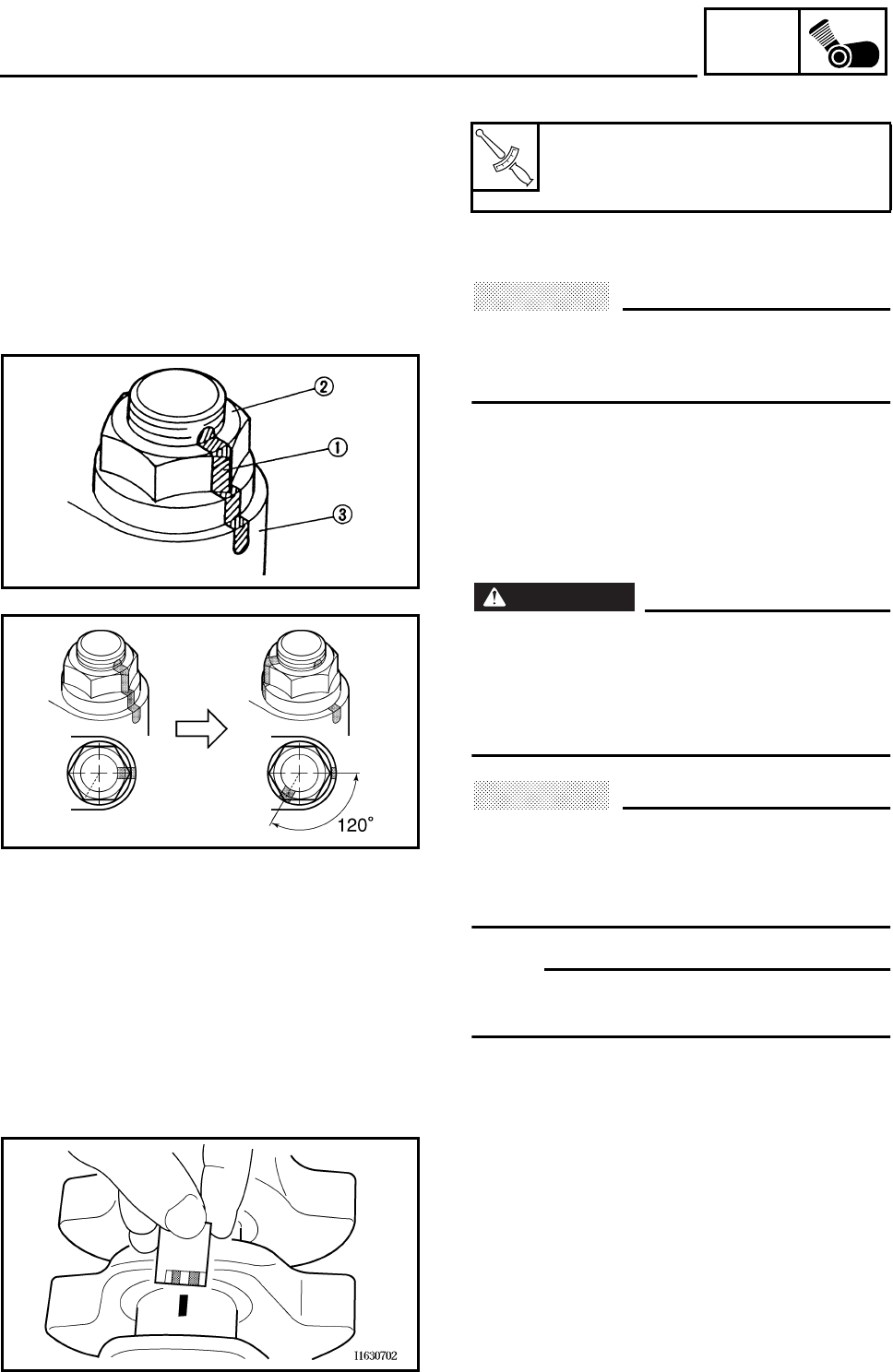

i. Put a mark 1 on the corner of the connect-

ing rod nut 2 and the connecting rod 3.

j. Tighten the nuts further to reach the speci-

fied angle (120°).

WARNING

When the nut is tightened more than the

specified angle, do not loosen the nut and

then retighten it.

Replace the bolt with a new one and per-

form the procedure again.

CAUTION:

• Do not use a torque wrench to tighten the

nut to the specified angle.

• Tighten the nut until it is at the specified

angles.

NOTE:

When using a hexagonal nut, note that the

angle from one corner to another is 60°

k. Remove the connecting rod and big end

bearings.

l. Measure the compressed Plastigauge

®

width on the crankshaft pin.

If the crankshaft-pin-to-big-end-bearing

clearance is out of specification, select

replacement big end bearings.

▲▲▲▲ ▲ ▲▲▲▲▲▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲▲▲

T

R

.

.

Connecting rod nut

20 Nm (2.0 m · kg, 14 ft · lb) +

120°