5 - 67

ENG

CONNECTING RODS AND PISTONS

b. If out of specification, replace the cylinder,

and the pistons and piston rings as a set.

Cylinder bore “C”

74.00 ~ 74.01 mm

(2.9134 ~ 2.9138 in)

Wear limit

74.06 mm

(2.9157 in)

Taper limit “T” 0.05 mm (0.002 in)

Out of round “R” 0.05 mm (0.002 in)

“C” = maximum of D

1

~ D

6

“T” = maximum of D

1

or D

2

– maximum of

D

5

or D

6

“R” = maximum of D

1

D

3

or D

5

– minimum

of D

2

D

4

or D

6

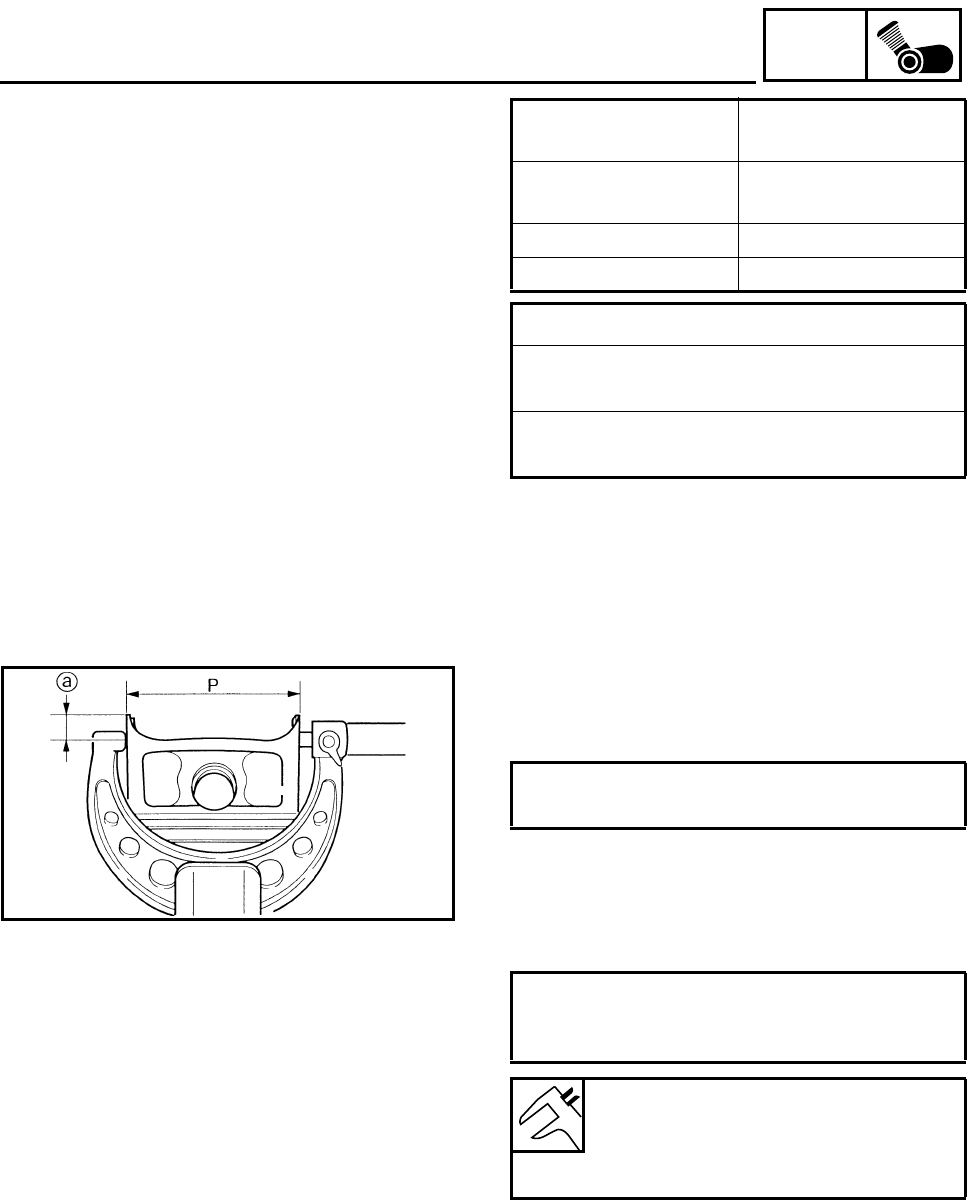

c. Measure piston skirt diameter “P” with the

micrometer.

a

5 mm from the bottom edge of the piston

d. If out of specification, replace the piston and

piston rings as a set.

e. Calculate the piston-to-cylinder clearance

with the following formula.

f. If out of specification, replace the cylinder,

and the piston and piston rings as a set.

▲▲▲▲ ▲ ▲▲▲▲▲▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲▲▲

Piston size “P”

73.975 ~ 73.990 mm (2.9124 ~ 2.9130 in)

Piston-to-cylinder clearance =

Cylinder bore “C” –

Piston skirt diameter “P”

Piston-to-cylinder clearance

0.010 ~ 0.035 mm

(0.0004 ~ 0.0014 in)

<Limit>: 0.12 mm (0.0047 in)