5 - 25

ENG

VALVES AND VALVE SPRINGS

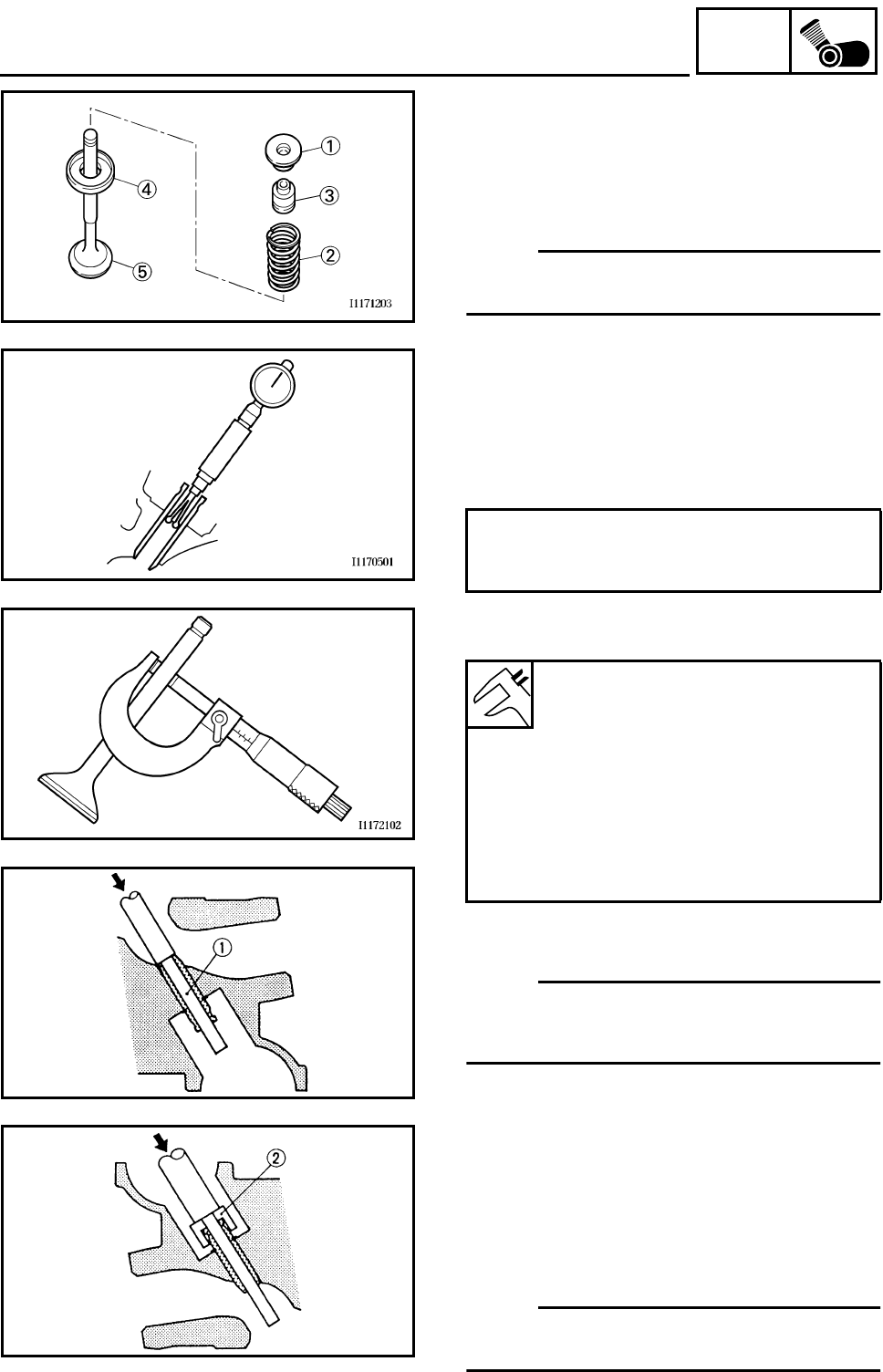

4. Remove:

• upper spring seat 1

• valve spring 2

• valve stem seal 3

• lower spring seat 4

• valve 5

NOTE:

_

Identify the position of each part very carefully

so that it can be reinstalled in its original place.

EAS00239

CHECKING THE VALVES AND VALVE

GUIDES

The following procedure applies to all of the

valves and valve guides.

1. Measure:

• valve-stem-to-valve-guide clearance

Out of specification → Replace the valve

guide.

2. Replace:

• valve guide

NOTE:

_

To ease valve guide removal and installation,

and to maintain the correct fit, heat the cylinder

head to 100 °C in an oven.

▼▼▼▼ ▼ ▼▼▼▼▼▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼▼▼

a. Remove the valve guide with the valve

guide remover 1.

b. Install the new valve guide with the valve

guide installer 2 and valve guide remover 1.

c. After installing the valve guide, bore the

valve guide with the valve guide reamer 3

to obtain the proper valve-stem-to-valve-

guide clearance.

NOTE:

_

After replacing the valve guide, reface the

valve seat.

Valve-stem-to-valve-guide clearance =

Valve guide inside diameter

È

–

Valve stem diameter

É

Valve-stem-to-valve-guide clear-

ance

Intake

0.0010 ~ 0.0037 mm

(0.0004 ~ 0.0015 in)

<Limit>: 0.08 mm (0.0031 in)

Exhaust

0.020 ~ 0.047 mm

(0.0008 ~ 0.0019 in)

<Limit>: 0.10 mm (0.0039 in)

È

É