2-8 / Installation & Operation CI-ControlWave EFM

2.3.1 Mounting the ControlWave EFM Enclosure

When mounting one of these units, it is to be positioned in accordance with the following

restrictions:

- The unit is to be positioned vertically with the Multivariable Transducer (MVT) at its

base and is to be mounted to a wall or a vertical 2” pipe (clamed at the rear of the unit

via two clamps and four bolts). If used, the 2” pipe is to be anchored in cement (deep

enough to conform to local building codes associated with frost considerations). The

basic unit measures 14.55” in height by 13” in width by 6.875” in depth. A Mul-

tivariable Transducer adds 2.8” to the unit’s height. See Figures 2-3 and 2-4.

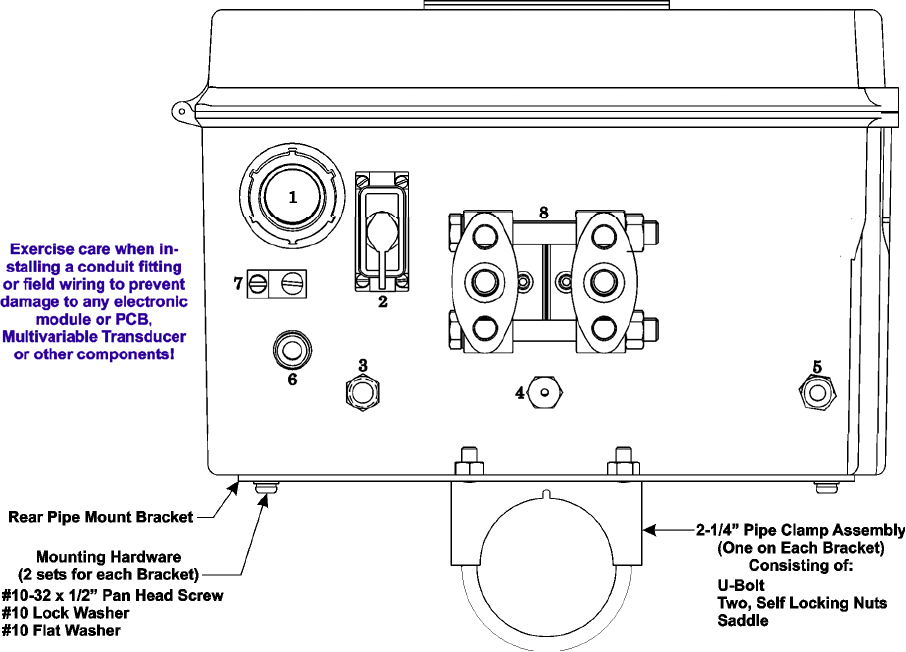

(1) 1” NPT Conduit Hub (2) Local Port D-Type Jack

(3) RTD Cable Assembly or Sealing Plug Male D-Type Jack or

(5) 5” Liquid Tight Conduit Fitting or Plug Circular Female Jack

(7) Solderless Ground Lug (4) Battery Ventilation Assembly

(8) Multivariable Transducer (6) Ant. Cable Fitting, Polyphaser,

or Plug

Figure 2-3 - ControlWave EFM Bottom View

- The Multivariable Transducer (MVT) is bolted to a process manifold which in-turn is

connected to the main (meter run) directly or via two pipes (see Figures 2-5 - 2-7).

- The unit must be positioned so that the front of the assembly is visible and the unit is

accessible for service, i.e., installing an option or replacement of the Lithium Battery,

or installation/removal of any ControlWave EFM Module.

- Make certain that the LCD Display/Keypad is accessible and visible to the on-site

operator.