CI-ControlWave EFM Appendix C - Hardware Installation Guide / C-3

Step 1. Hardware Configuration (Continued)

2. Remove the System Controller Module (SCM) and after configuring its configuration

jumpers, install it in chassis slot 1, i.e., the first slot from the left end of the Base

Assembly Chassis (see Section 2.3.2).

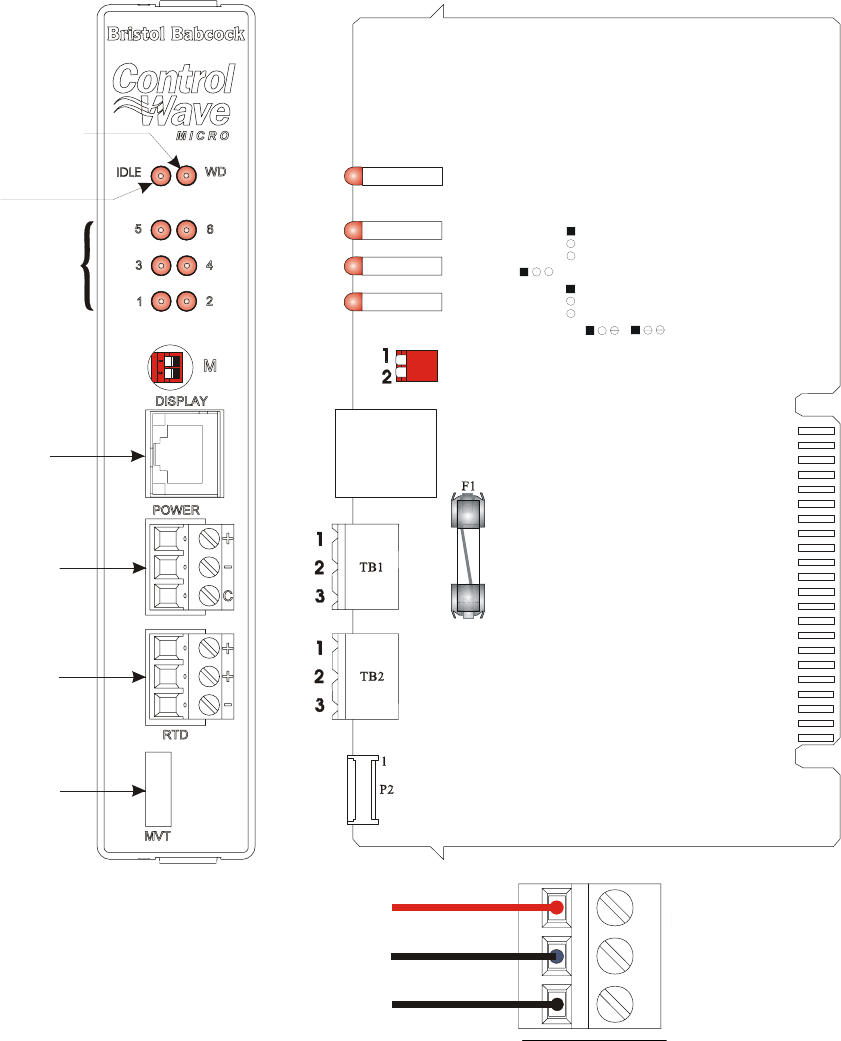

JP5, JP6, JP7, JP8 & JP9

1-to-2 Installed = 12V Bulk System

2-to-3 Installed = 6V Bulk System

P1

1

1

2

JP9

JP8

JP6

JP5

JP7

1

1

1

CR27

CR26

CR25

CR24

(Red)

I DLE LED

(Red)

Sta us LEDs

TB1

Input Power

Connector

(Red)

WATCHDOG LED

TB2

RTD Interface

Connector

P2

MVT Interface

Connector

J2

Display Intf.

Connector

1A

J2

RJ- 4 5

TB 1- 1

TB 1- 2

TB 1- 3

(+4.5/4.9Vdc to +16.0Vdc for +6V supply)

+VIN (+9.6/10.3Vdc to +16.0Vdc for +12V supply)

-VIN (Supply Ground)

Chassis Ground (CHASSIS)

+VIN

1

3

-VIN

CHASSIS

Bulk Supply #1 Pos. Term.

Bulk Supply #1 Neg. Term.

Chassis Ground

SW1 = Mode Switch

Figure C-2 - SCM Component Identification and TB1 Wiring Diagram

3. Remove the CPU Module. Make sure that the Lithium Backup Battery has been

enabled, i.e., Backup Battery Board Jumper JP1 should be installed (on its jumper

posts). After configuring the CPU Module’s DIP-Switches (see Section 2.3.3), install it

into ControlWave EFM Base Assembly, chassis slot 2, i.e., the second slot from the left

end of the Base Assembly Chassis. Tables C-1, C-2 and C-3 provide an overview of

switch settings (see Tables C-1, C-2, C-3 and Figure C-3).