Section 4

Page 83

Downlook Ultrasonic Sensor

4.10.2 Ultrasonic Senor (Downlook) Installation Troubleshooting

Convection Currents

Convection components between the sensor and target will change the

velocity of sound. If these conditions are present, install a shield around the

sound beam to eliminate temperature variation due to convection currents.

The system is designed with averaging routines to help mitigate this problem.

The acoustical impedance of foam and oil is low relative to air. While the 980

is designed with an AGC (Automatic Gain Control) scheme to reduce these

factors it is recommended that sites without these anomalies be selected.

Obstructions

Through the use of an Invisible Range, the 980 Flow Meter can select targets

beyond peripheral obstructions. In establishing this exclusion zone, care must

be taken to set the exclusion zone higher than the maximum expected level.

Echo Loss

It is normal to report some temporary echo loss due to environmental effects

mentioned above. The 980 will determine if the sound intensity is below

recommended values and automatically initiate subsequent measurements to

provide an accurate reading. If echo loss events are in excess of two per hour,

site conditions should be reexamined for convection currents caused by

sunlight or thermal gradients at the water ambient interface. Foam on the

liquid’s surface may also cause echo loss.

Transducer Ringing

Ringing can occur if the transducer is operating within the deadband.

Transducer ringing means that the transducer may not have finished

transmitting a pulse of sound when the echo returned. Sufficient distance

between the sensor and the target will eliminate transducer ringing.

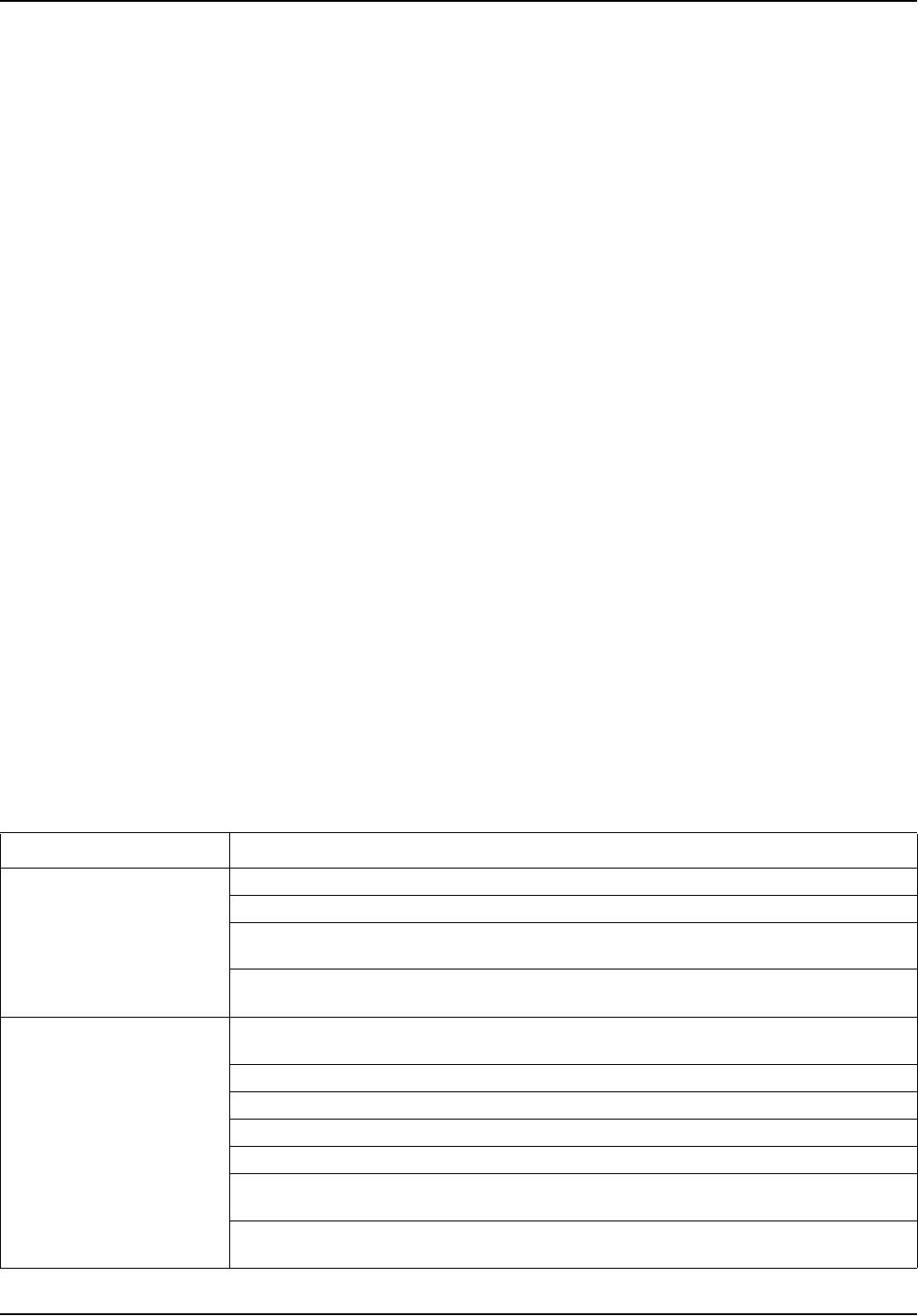

Problem/Error Message Possible Causes and Solutions

Ultrasonic Failure

(No signal from sensor)

Check the connection between the flow meter and the sensor.

Check the sensor cable. The cable may be cut or broken.

Recalibrate the sensor. Look for unusual temperature or the inability for a new calibrated level

to be read.

Try a different sensor on the same flow meter to rule out instrument problems and try a

different flow meter with the same sensor to rule out sensor problems.

Echo Loss

(Flow meter is not getting a

return signal from the sensor)

Check for excessive foam on the water surface. Foam may cause sound waves to be

absorbed rather than reflected.

Check the sensor cable for cuts or nicks.

Check the connection between the flow meter and the sensor.

Make sure that the sensor is level. The sensor must be level for proper return of the signal.

Try shielding the transducer from convection currents.

Repeat the temperature calibration procedure. If the unit reads extreme high or low

temperatures, the sensor may have a bad temperature sensor.

Try a different sensor on the same flow meter to rule out instrument problems and try a

different flow meter with the same sensor to rule out sensor problems.