ENGINE

3.35

4. Measure piston ring to groove clearance by

placing the ring in the ring land and measuring

with a thickness gauge. Replace piston and rings

if ring-to-groove clearance exceeds service

limits.

Piston

Ring

Feeler Gauge

Piston Ring-to-Ring Groove Clearance

Refer To Engine Service Data

Pg. 3.12 -- 3.14

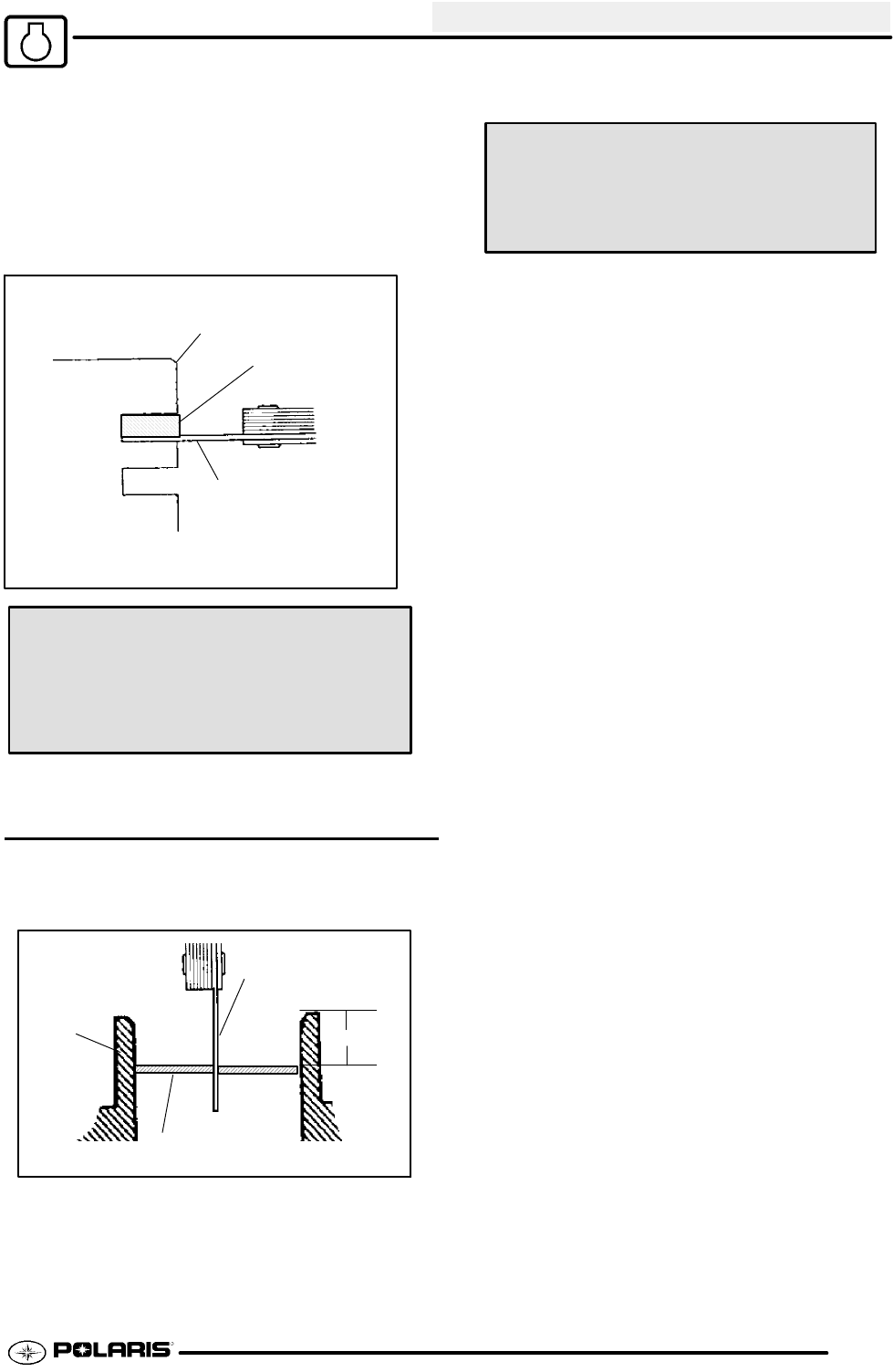

PISTON RING INSTALLED GAP

1. Place each piston ring (A) inside cylinder (B)

using piston to push ring squarely into place as

shown. (See next page)

25-50mm

B

A

C

Piston Ring Installed Gap

Refer To Engine Service Data

Pg. 3.12 -- 3.14

NOTE: Ring should be installed with the mark facing

upward.

2. Measure installed gap with a feeler gauge (C) at

both the top and bottom of the cylinder.

REMINDER: A difference in end gap indicates

cylinder taper. The cylinder should be measured

for excessive taper and out of round.

3. If the bottom installed gap measurement exceeds

the service limit, replace the rings. If ring gap is

smaller than the specified limit, file ring ends until

gap is within specified range.

NOTE: Always check piston ring installed gap after

re-boring a cylinder or when installing new rings. A

re-bored cylinder should always be scrubbed

thoroughly with hot soapy water, rinsed, and dried

completely. Wipe cylinder bore with oil immediately to

remove residue and prevent rust.