CLUTCH

6.21

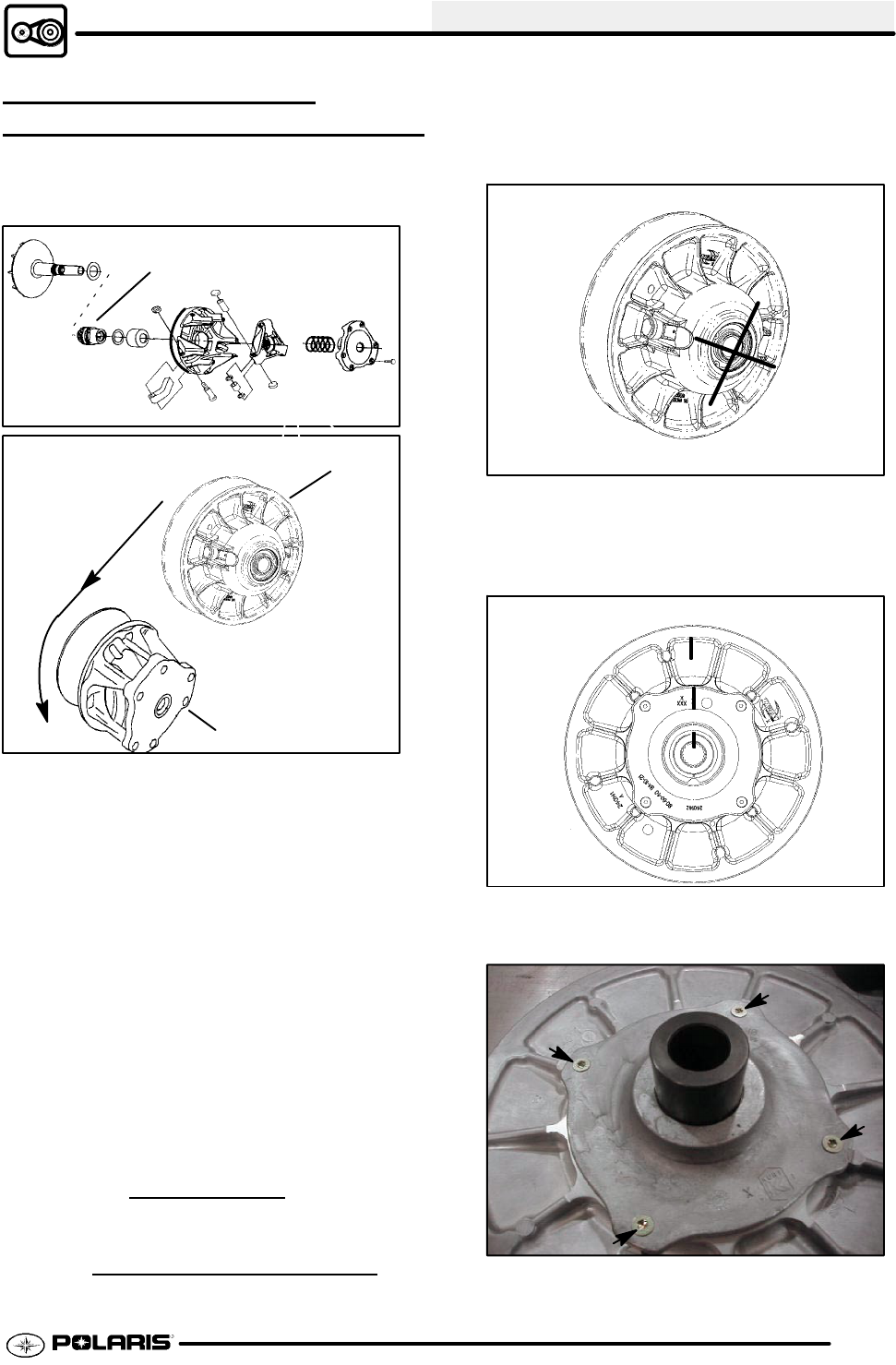

EBS DRIVEN CLUTCH

DISASSEMBLY/INSPECTION

-

EBS Driven Clutch Operation

This EBS driven clutch provides the same engine

braking abilities as the earlier EBS driven clutch.

One--way Clutch

Drive Clutch

Belt Rotation

Downhill

Drive

Driven

When the ATV is moving downhill the drive train turns

the driven clutch, belt, and one way clutch in the

direction of engine rotation. When the one--way

clutch (see exploded viewof drive clutch) exceeds the

drive clutch rotational speed, the one--way clutch

locks to the drive clutch shaft and engine braking

occurs. Essentially the driven clutch has become the

“driving” clutch. The spider assembly with the two

rollers, that is fixed to the transmission shaft rotates

in the pockets of the sheave, allowing the stationary

sheave to rotate with the moveable sheave as the

rollers move to the other side of the ramp, providing

instant EBS braking. Engine braking (EBS) continues

until the drive clutch speed exceeds the one--way

clutch speed, or until the throttle is applied and the

engine reaches clutch engagement speed, lifting the

belt off of the one--way clutch.

CAUTION: The driven clutch must be

disassembled from the helix end

to reducespring

pressure. Review all information below before

proceeding.

DRIVEN DISASSEMBLY/ASSEMBLY

1. Remove driven clutch from the transmission input

shaft. Do not attempt disassembly of the driven

clutch from the outside snap ring. The driven

clutch must be disassembled from the helix side.

Do not disassemble from this side

2. It is important to mark the position of the shaft,

cam cover, and sheave before disassembly or

use the “X”s on the components for reference.

This will aid in reassembly and helps to maintain

clutch balance after reassembly.

Mark Components Before Disassembly

3. Remove the four torx screws that secure the cam

assembly (helix) using a T25 torx.

4. Place the driven assembly intothe Clutch Holding

Tool (PU--47086). Install the compression