ENGINE

3.27

VALVE SEAT RECONDITIONING CONT”D

8. Clean all filings from the area with hot soapy

water, rinse, and dry with compressed air.

WARNING

Wear eye protection or a face shield when

working with compressed air during cylinder

head disassembly and reassembly.

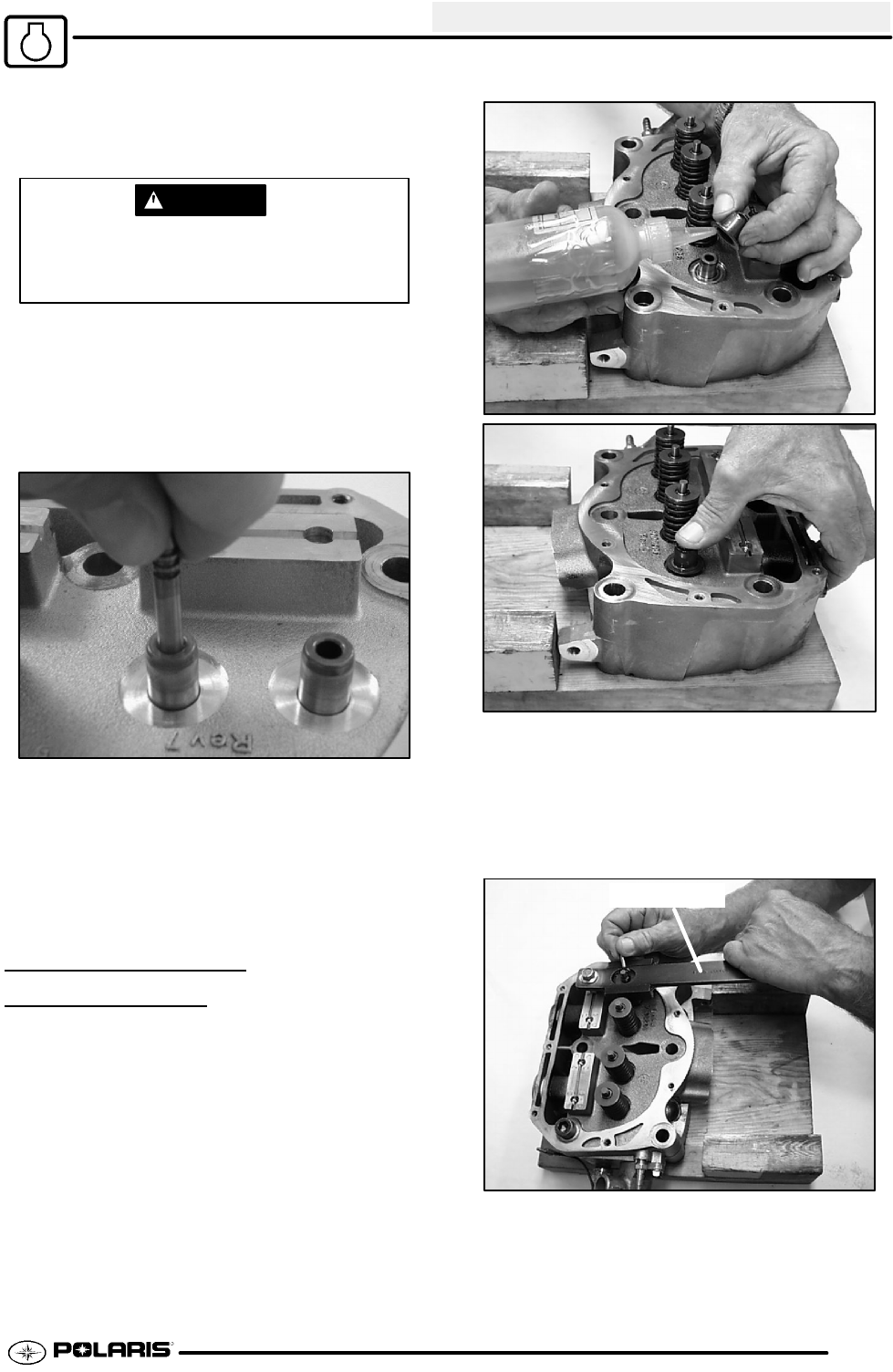

9. Lubricate the valve guides with clean engine oil,

and apply oil or water based lapping compound to

the face of the valve. NOTE: Lapping is not

required with an interference angle valve job.

10. Insert the valve into its respective guide and lap

using a lapping tool or a section of fuel line

connected to the valve stem.

11. Rotate the valve rapidly back and forth until the

cut sounds smooth. Lift the valve slightly off of the

seat, rotate 1/4 turn, and repeat the lapping

process. Dothis four to five times untilthe valve is

fully seated, and repeat process for the other

valve(s).

12. Thoroughly clean cylinder head and valves.

CYLINDER HEAD

REASSEMBL

Y

NOTE: Assemble the valves one at atime tomaintain

proper order.

1. Apply engine oil to valve guides and seats.

2. Coat valve stem with molybdenum disulfide

grease or 0W--40 Synthetic oil.

3. Install valve carefully with a rotating motion to

avoid damaging valve seal.

4. Valve seals should be installed after the valves

are in the headto avoid valve sealdamage. Install

new valve seals on valve guides.

5. Dip valve spring and retainer in clean engine oil

and install.

6. Place retainer on spring and install Valve Spring

Compressor (PU--45257). Install split keepers

with the gap even on both sides. NOTE: A small

parts magnet can aid in installation of the

keepers.

(PU--45257)

7. Repeat procedure for remaining valves. When all

valves are installed, tap lightly with soft faced

hammer on the end of the valves to seat the split

keepers. NOTE: To prevent damage to the valve

seals, do not compress the valve spring more

than necessary to install the keepers.