FUEL SYSTEM / FUEL INJECTION

4.12

FUEL PRESSURE REGULATOR TEST

Refer to the Fuel Pump Test procedure.

FUEL PRESSURE REGULATOR

REPLACEMENT

The regulator is a sealed, non--serviceable assembly.

If it is faulty, the pump assembly must be replaced.

Refer to the Fuel Pump/Tank Assembly Replacement

procedure.

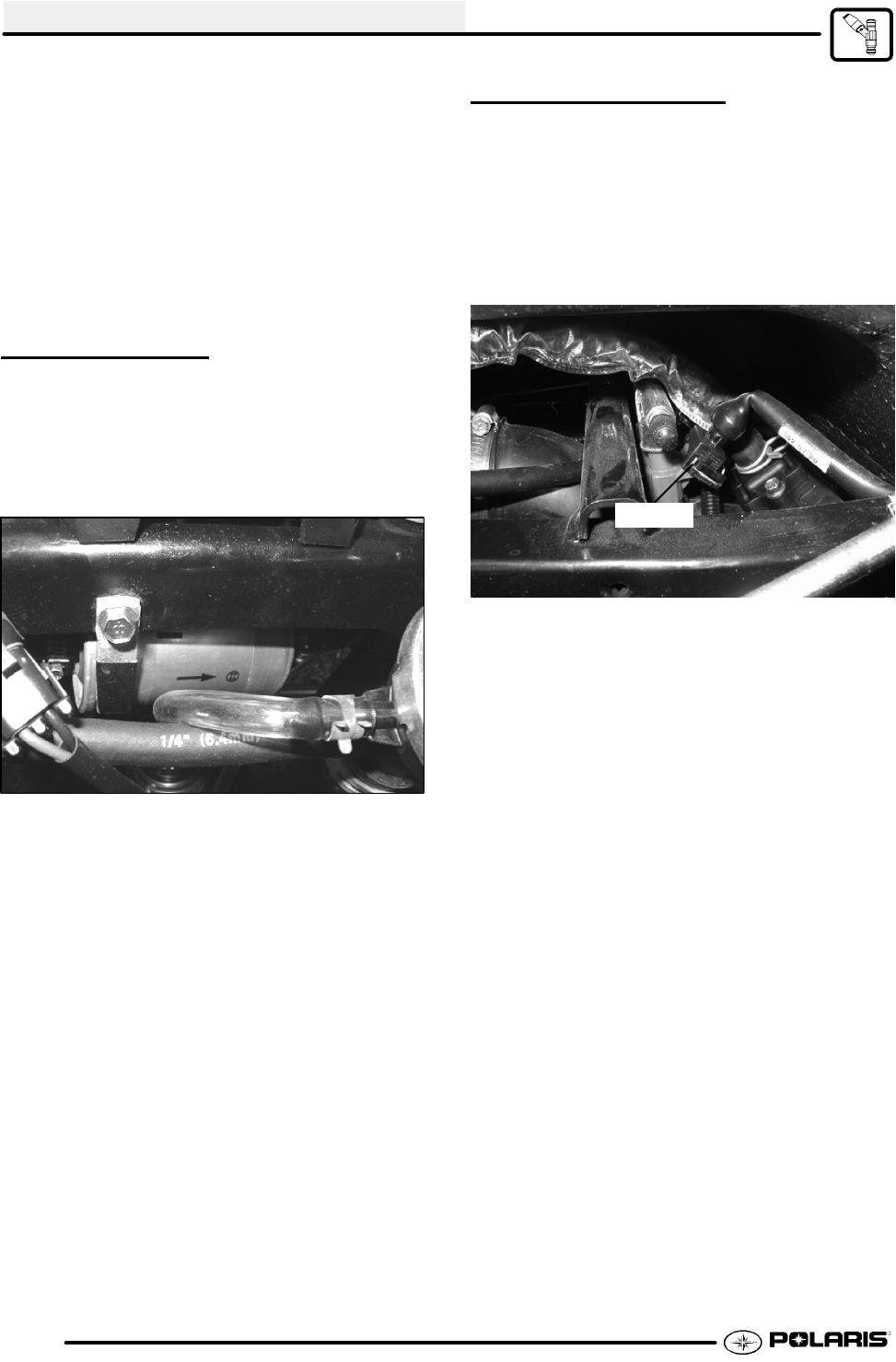

FUEL FILTERS

NOTE: 800 EFI fuel connections are quick--connect

couplings vs 700 EFI connections.

EFI Engines use a non--serviceable, high--volume,

high--pressure, 30--micron internal fuel pump filter

and a replaceable 10--micron, in--line fuel filter.

700 EFI Shown

FUEL FILTER SERVICE

In line filter replacement is recommended every 2

years of operation or more frequently under extremely

dusty, dirty conditions. Use only the specified filter,

and install it according to the directional arrows. DO

NOT use an aftermarket filter, as operating

performance and safety can be affected.

FUEL FILTER REPLACEMENT

To replace the filter:

1. Relievesystem pressure through the test valve in

the fuel rail before servicing.

2. Loosen clamps and slide hose off the filter ends.

3. Install new filter with arrow pointing to the fuel line

connected to the injector rail.

NOTE: When replacing the fuel filter, wet the interior

of the new filter with gasoline before installation to

ensure high pump pressure doesn’t tear the filtering

material.

FUEL INJECTORS

NOTE: 800 EFI fuel connections are quick--connect

couplings vs 700 EFI connections.

The fuel injectors mount into the intake manifold, and

the fuel rail attaches to them at the top end.

Replaceable O--Rings on both ends of the injector

prevent external fuel leakage and also insulate it from

heat and vibration.

Injector

When the key switch is on, the fuel rail is pressurized,

and voltage is present at the injector. At the proper

instant, the ECU completes the ground circuit,

energizing the injector. The valve needle in the

injector is opened electromagnetically, and the

pressure in the fuel rail forces fuel down through the

inside. The ”director plate” at the tip of the injector (see

inset) contains a series of calibrated openings which

directs the fuel into the intake port in a cone--shaped

spray pattern.

The injector is opened and closed once for each

crankshaft revolution, however only one--half the total

amount of fuel needed for one firing is injected during

each opening. The amount of fuel injected is

controlled by the ECU and determined by the length

of time the valve needle is held open, also referred to

as the .’injection duration” or”pulse width”. It mayvary

in length from 1.5--8 milliseconds depending on the

speed and load requirements of the engine.