Troubleshooting

Introduction

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 105

7/08

Troubleshooting

Introduction

Troubleshooting procedures can be followed when inaccurate or faulty actuator operation is detected. In

this section, troubleshooting procedures consist of a few simple flow charts to test for proper function of

various actuator components. Component replacement is at the PWA or assembly level.

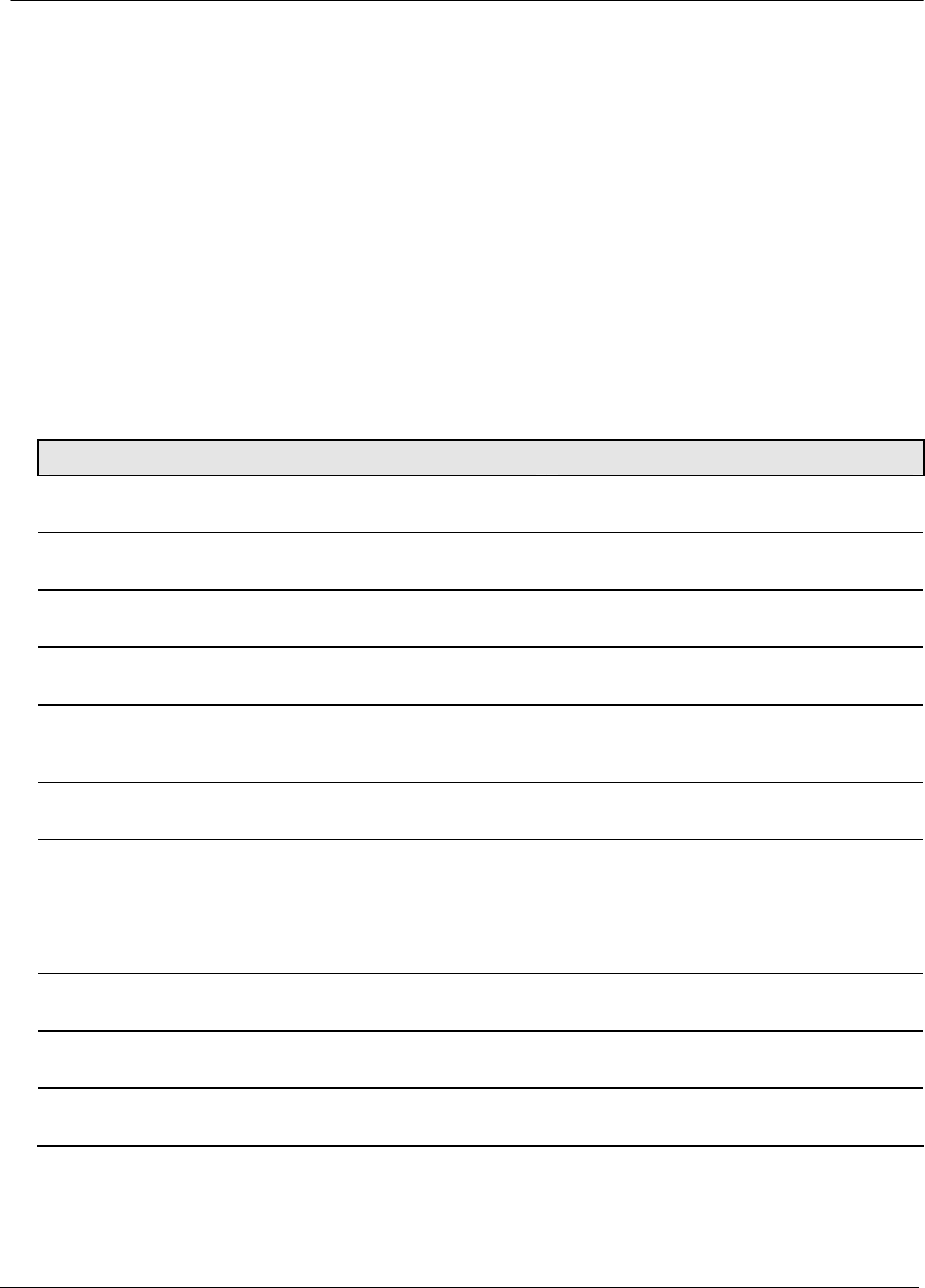

Table 39 indicates some of the observable symptoms of failure that can be identified by noting the faulty

actuator operation.

Table 39 Observable Symptoms of Failure

Symptom Procedure

No Actuator current output.

Replace CPU Assembly

No Actuator slidewire output.

Replace CPU Assembly

Local display does not light.

See

Figure 42

Actuator fails one or more power up diagnostics.

See

Figure 43

Actuator motor does not drive in response to input signal.

Perform input calibration.

See

Figure 42

Actuator motor does not drive to proper position.

Perform motor calibration.

Actuator Motor is “Hunting”

(Motor does not drive to a position and stop.)

Process control loop is not tuned correctly.

Refer to the Instruction Manual for your

controller on how to tune a loop.

Increase the Deadband in the Actuator

and/or in the control loop.

Position sensor position is not correct.

See page

85.

Auto/Manual Switch does not operate correctly.

See

Figure 45

Relay(s) does not operate.

See

Figure 46