11.40

Measuring big end bearing play

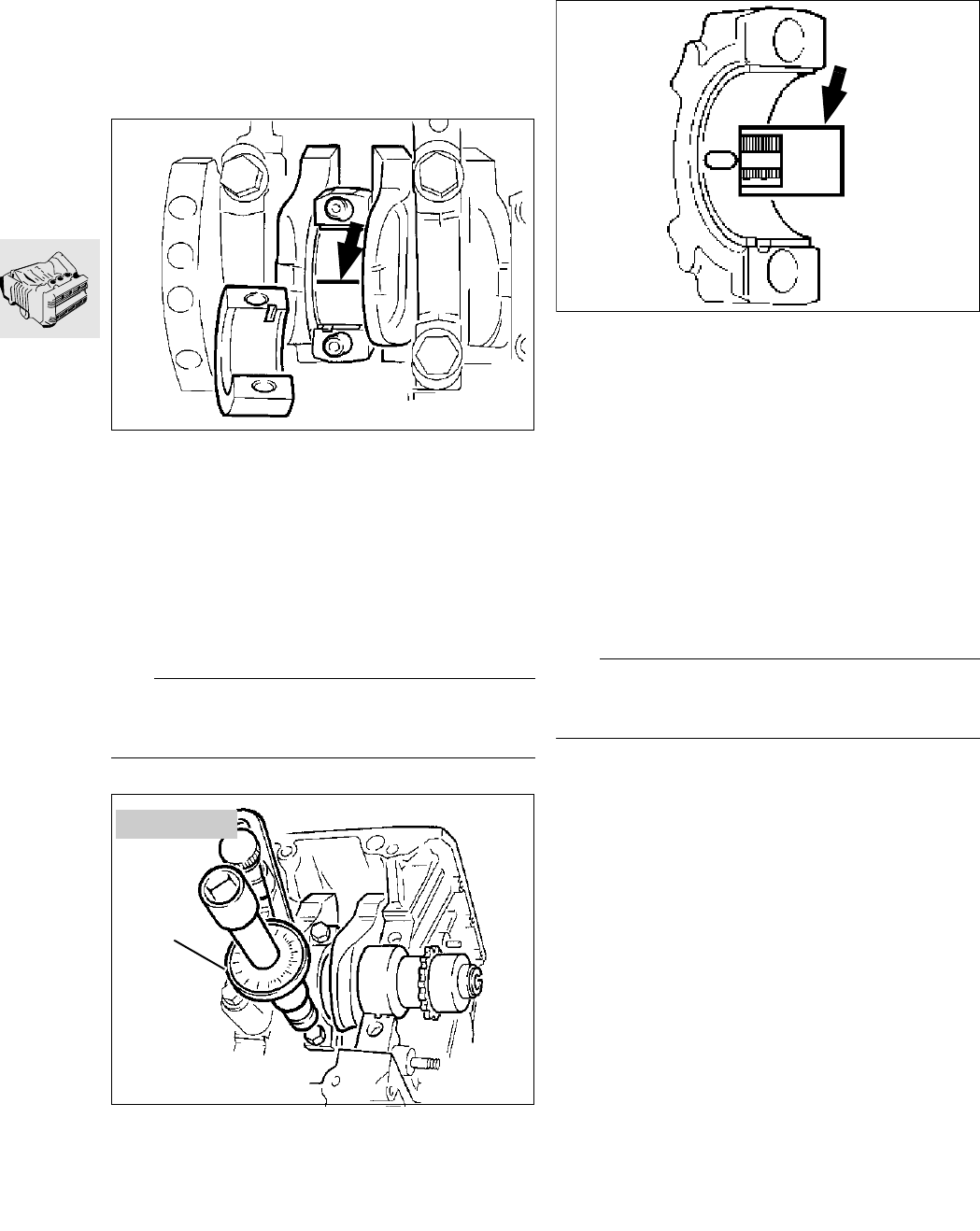

•

Turn the crankpin 30° away from bottom dead

centre.

•

Wipe oil off crankpin and bearing cap.

•

Place Plastigage strip (arrow), Type PG-1,

BMW No.002590, over the entire width of the

bearing, 6…8 mm (0.24…0.32 in) away from the

centre of the crankpin.

•

Attach the bearing caps with the joint lines

aligned, and tighten them.

X Tightening torque:

Big end bearings.......................................... 30 Nm

L Note:

The crankshaft must not be turned any more at this

stage.

•

Tighten the big end bearings with wrench angle

indicator (1), BMW No. 11 2 210.

X Tightening torque:

Wrench angle .................................................. 80°

•

Unscrew and remove the bearing cap.

•

Determine bearing play against comparison

scale (arrow).

Bearing

play.............0.030…0.066 mm (0.0012…0.0026 in)

Wear limit.............................. 0.130 mm (0.0051 in)

•

If bearing shells are renewed, note paint marks

on crankpin and on big end bearing.

•

Regrinding stages “0” and “1” are available; the

crankpins are marked with a corresponding

number of paint spots.

•

If there are no paint spots, this indicates regrind-

ing stage “0”.

L Note:

The crankshaft can only be reground in stage “0”,

and must be hardened and finished afterwards.

Installing big end bearing

•

Move the crankpin of the cylinder concerned to

bottom dead centre.

•

Oil the crankpin and attach the conrod.

•

Pull the protective tubes off the bolts.

•

Attach the bearing caps with the joint lines

aligned, and tighten them.

X Tightening torque:

Big end bearings.......................................... 30 Nm

•

Using wrench angle indicator,

BMW No. 11 2 500, tighten the big end bearing.

X Tightening torque:

Wrench angle.................................................... 80°

LT110610

LT110620

11 2 210

1

LT110630