46.22

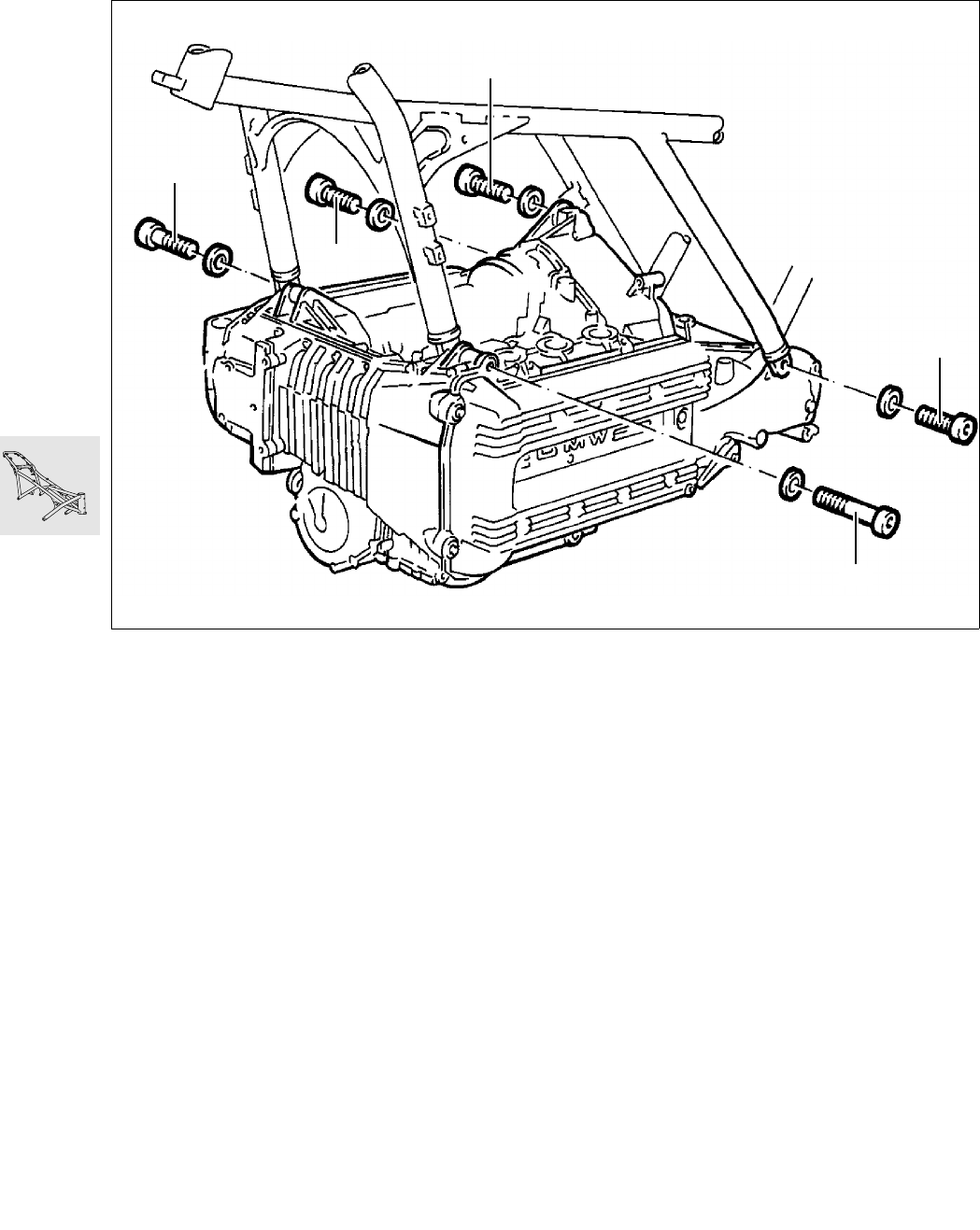

Installing frame

•

Installation basically takes place in the reverse

order of removal.

•

Place frame on drive train and firmly tighten

screws and bolts in the specified order.

1. Screw in all 5 screws loosely, i.e. not as far as

they will go. Fit a 1 mm thick spacer ring, inner

support ring at the front right between the cylin-

der head and frame strut.

2. Firmly tighten screws 1,4 and 3.

3. Measure distance at front left and fit outer sup-

port ring, firmly tighten screws.

4. Measure distance of mounting point on interme-

diate flange and firmly tighten screw.

X Tightening torque:

Frame to engine ........................................... 45 Nm

•

Install telescopic fork and adjust steering.

Setting torque:

Hexagon nut................................................ 12 Nm

New bearing adjustement procedure:

Pre-tighten hexagon nut to........................... 25 Nm

Move steering from stop to stop several times,

loosen hexagon nuts, retighten .................... 12 Nm

X Tightening torques:

Locking tube................................................ 65 Nm

Hexagon nut ................................................ 65 Nm

Clamping screws of fork bridge.................... 15 Nm

Clamping block for handlebar ...................... 22 Nm

Setting dimensions:

Clutch play at handlebar

lever....................... 4 ± 0,5 mm (0.157 ± 0.0197 in)

Cable length at clutch release

lever............................ 75 ± 1 mm (2.953 ± 0.04 in)

Accelerator cable play............. 0,75 mm (0.0295 in)

•

Carefully fill and bleed brake system

X Tightening torques:

Brake line to handbrake cylinder.................. 11 Nm

Brake line to distributor................................ 11 Nm

Brake line to brake caliper.............................. 7 Nm

Bleed screw................................................... 7 Nm

[ABS II] Pressure modulator to holder ......... 17 Nm

LT460300

2

3

4

1

5