3.35

ENGINE

3

9923142 - 2011 RANGER RZR / RZR S / RZR 4 Service Manual

© Copyright 2010 Polaris Sales Inc.

Cylinder Hone Selection and Honing

Procedure

Cylinders may be wet or dry honed depending upon the hone

manufacturer’s recommendations. Wet honing removes more

material faster and leaves a more distinct pattern in the bore.

Honing To Deglaze

A finished cylinder should have a cross-hatch pattern to ensure

piston ring seating and to aid in the retention of the fuel/oil

mixture during initial break in. Hone cylinder according to hone

manufacturer's instructions, or these guidelines:

• Honing should be done with a diamond hone. Cylinder

could be damaged if the hone is not hard enough to

scratch the nicasil lining.

• Use a motor speed of approximately 300-500 RPM, run

the hone in and out of the cylinder rapidly until cutting

tension decreases. Remember to keep the hone drive

shaft centered (or cylinder centered on arbor) and to

bring the stones approximately 1/2” (1.3 cm) above and

below the bore at the end of each stroke.

• Release the hone at regular intervals and inspect the

bore to determine if it has been sufficiently de-glazed,

and to check for correct cross-hatch.

NOTE: Do not allow cylinder to heat up during honing.

• After honing has been completed, inspect cylinder for

thinning or peeling.

If cylinder wear or damage is excessive, it will be necessary to

replace the cylinder. The cylinders are lined with a nicasil

coating and are not repairable. Hone only enough to de-glaze the

outer layer of the cylinder bore.

IMPORTANT: Clean the cylinder after honing

If cylinder wear or damage is excessive, it will be necessary to

replace the cylinder. The cylinders are lined with a nicasil

coating and are not repairable. Hone only enough to de-glaze the

outer layer of the cylinder bore.

Cleaning the Cylinder After Honing

It is very important that the cylinder be thoroughly cleaned after

honing to remove all grit material. Wash the cylinder in a

solvent, then in hot, soapy water. Pay close attention to areas

where the cylinder sleeve meets the aluminum casting (transfer

port area). Use electrical contact cleaner if necessary to clean

these areas. Rinse thoroughly, dry with compressed air, and oil

the bore immediately with Polaris Lubricant.

CAUTION

A hone which will straighten as well as remove

material from the cylinder is very important.

Using a common spring loaded glaze breaker

for honing is not advised for nicasil cylinders.

Polaris recommends using a rigid hone or arbor

honing machine. Cylinders may be wet or dry

honed depending upon the hone manufacturer's

recommendations.

Wet honing removes more material faster and

leaves a more distinct pattern in the bore.

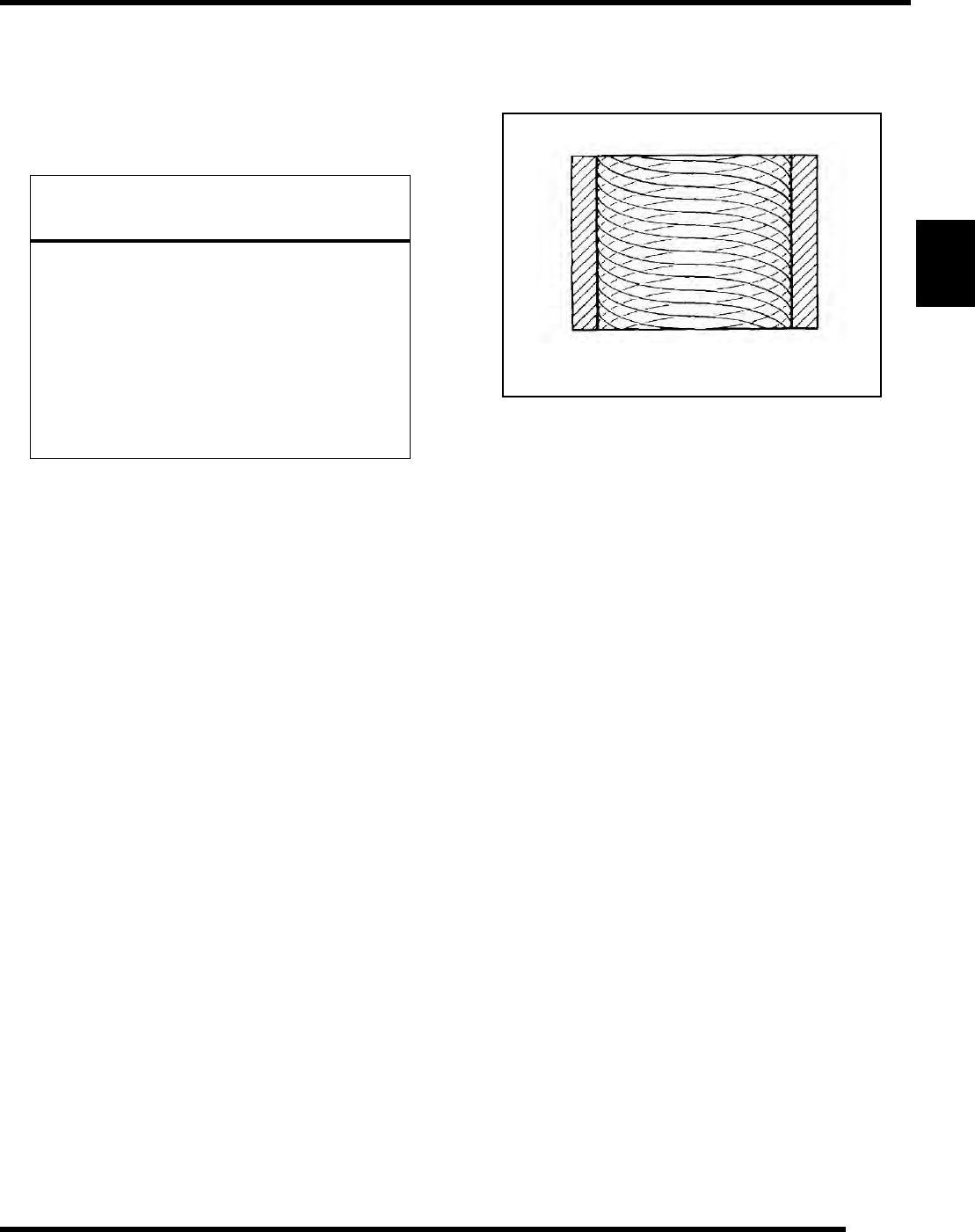

Example of Cross Hatch Pattern