4.17

ELECTRONIC FUEL INJECTION

4

9923142 - 2011 RANGER RZR / RZR S / RZR 4 Service Manual

© Copyright 2010 Polaris Sales Inc.

Fuel Injector Service

Injector problems typically fall into three general categories-

electrical, dirty / clogged, or leakage. An electrical problem

usually causes one or both of the injectors to stop functioning.

Several methods may be used to check if the injectors are

operating.

• With the engine running at idle, feel for operational

vibration, indicating that they are opening and closing.

• When temperatures prohibit touching, listen for a

buzzing or clicking sound with a screwdriver or

mechanic's stethoscope.

• Disconnect the electrical connector from an injector and

listen for a change in idle performance (only running on

one cylinder) or a change in injector noise or vibration.

NOTE: Do not apply voltage directly to the fuel

injector(s). Excessive voltage will burn out the

injector(s). Do not ground the injector(s) with the

ignition on. lnjector(s) will open/turn on if relay is

energized.

If an injector is not operating, it can indicate either a bad injector,

or a wiring/electrical connection problem. Check as follows:

Injector leakage is very unlikely, but in rare instances it can be

internal (past the tip of the valve needle), or external (weeping

around the injector body). The loss of system pressure from the

leakage can cause hot restart problems and longer cranking

times.

Injector problems due to dirt or clogging are unlikely due to the

design of the injectors, the high fuel pressure, the use of filters

and the detergent additives in the gasoline. Symptoms that could

be caused by dirty/clogged injectors include rough idle,

hesitation/stumble during acceleration, or triggering of fault

codes related to fuel delivery. Injector clogging is usually caused

by a buildup of deposits on the director plate, restricting the flow

of fuel, resulting in a poor spray pattern. Some contributing

factors to injector clogging include; dirty air filters, higher than

normal operating temperatures, short operating intervals and

dirty, incorrect, or poor quality fuel. Cleaning of clogged

injectors is not recommended; they should be replaced.

Additives and higher grades of fuel can be used as a preventative

measure if clogging has been a problem.

Fuel Injector Test

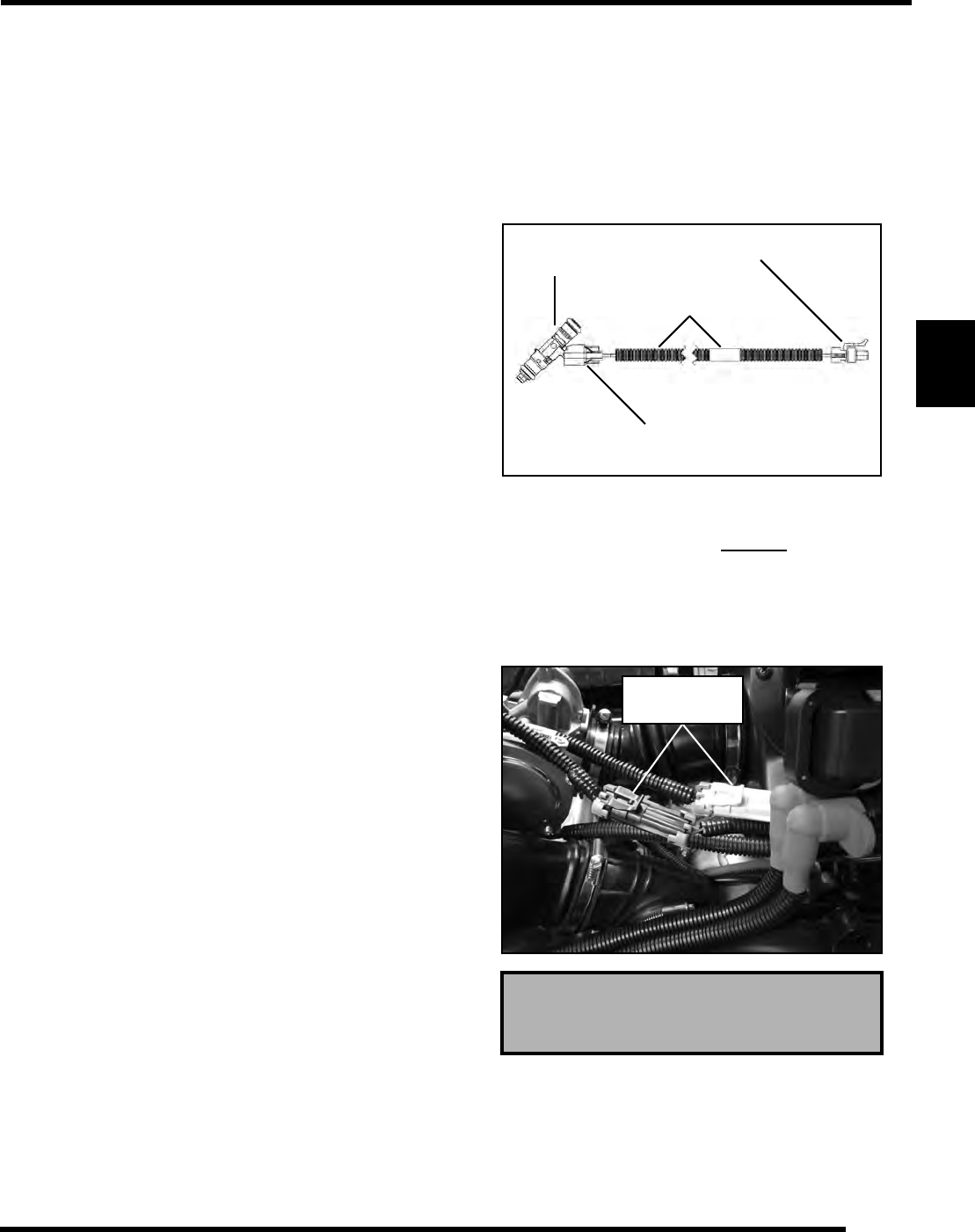

NOTE: The harness connector and locking spring is

bonded to the fuel injectors with an epoxy. DO NOT

attempt to disconnect the connector from the fuel

injectors. Damage will occur to the injector and/or

harness if attempting to separate at that location.

Separate the fuel injector from the vehicle harness

as shown in the illustration below.

IMPORTANT: Take note of PTO and MAG fuel injector

harness connectors before disconnecting them. The

harnesses are different and can not

be connected

incorrectly (PTO - Gray; MAG - Black).

The fuel injectors are non-serviceable. If diagnosis indicates a

problem with either injector, test the resistance of the fuel

injector(s) by measuring between the two harness pin terminals:

NOTE: Be sure to connect like colored fuel injector

connectors for proper engine function (PTO = GRAY,

MAG = BLACK).

Fuel Injector Resistance Specification:

11.4 - 12.6

Disconnect Here

DO NOT

Disconnect Here

Fuel

Injector

Harness

Disconnect

and test here